Uneven prints, is this the inconsistent extrusion problem?

Hi,

These are prints from my Prusa Mk3s+, the bearings move nice and are greased, the frame is aligned, the screws are nice and tight and the belts are within the range. one of the cubes is over a table and the other over a big ceramic tiled floor, so is not the vibration from the table.

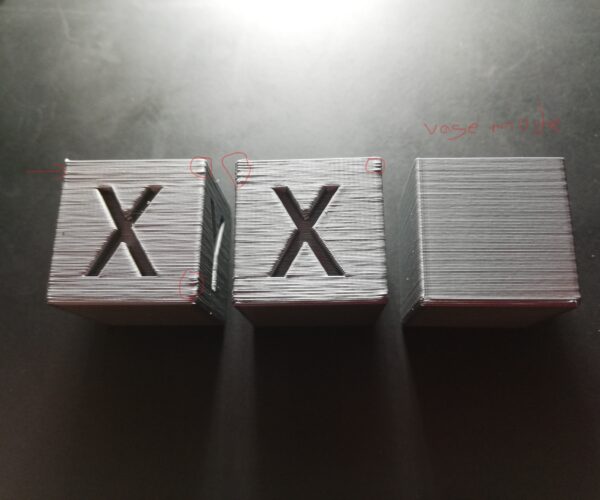

The top layers and bottom layers are fine, but not the vertical walls, with strong light, the issue is evident. however, is almost not present in vase mode.

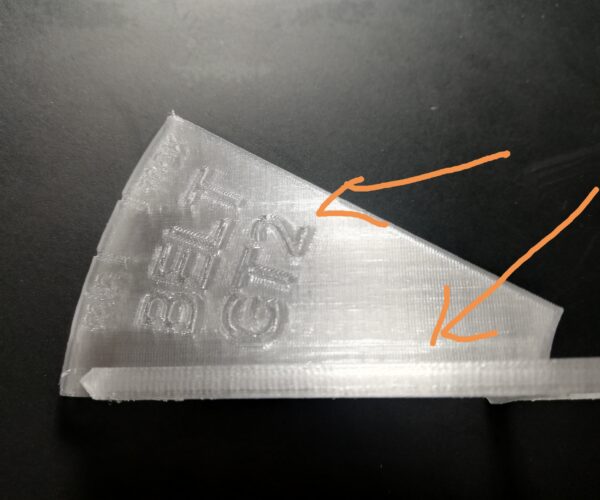

The same issue is also present in other filaments, like PETG (look at the belt tensioner tool I just print with a brand new filament). This does seem like the extrusion inconsistency problem, was this solved ( https://github.com/prusa3d/Prusa-Firmware/issues/602 )? seems it is not by looking at other posts! (uneven prints, walls, etc), where the calibration cubes have the most prominent defects in similar locations.

Is there a real explanation of this issue? or how to solve it?, (other than blaming mechanical problems) I have seen much better pictures of calibration cubes from the ender 3 and other printers.

I am a little disappointed at this point, tweaking any mechanical thing in this printer is a considerable effort, but no changes in the quality so far, any idea of how to improve this?

First be aware that it is possible to overtighten the X carriage.

For each axis:

With the power off, move the axis by hand; is is smooth? Does the resistance stay the same over the whole range?

Clean and lubricate the smooth rods, check they are not damaged/scratched. Check the idler pulley is not clogged, out of line, or damaged (loosen the belt and try turning it with your fingertip, is it smooth?)

With the belt loose try turning the stepper motor by hand; is is smooth?

Retighten the belt until it just begins to make a low musical note when plucked...

Then use your tension meter.

Cheerio,

everything is smooth

This is a brand new printer with less than 10h prints, everything is smooth and lubricated with prusa lube, and everything is pristine, no scratches. The X axis belt value is around 253, Y belt value around 278.

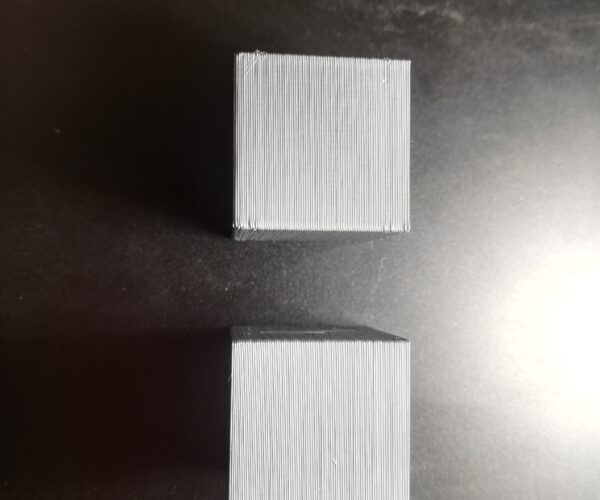

So No clue of what could be wrong, I even disassembled and realign/lubricate the X-axis (it was smooth anyways). After that the two cubes look almost identical with the same issues!

The only thing is that the belt tensioner tools were printed with overture PETG but with the same Prusament settings, the values are close to the minimum (I know the differences between materials) but the belt-test throws the values above consistently. I will try in any case to release a little bit of the X-axis belt, but I will need to disassemble the cover of the extruder, I cannot release it more at this point.

To be honest, this printer has a lot of design issues, maybe because I am an engineer I can see it very clearly. For example, just a couple, the X motor screw tensioner is a joke, basically, one contact point crushing, drilling, and removing the paint of the motor, really? Also, the idler pulleys with rollers are narrower than the belts and are held by a screw, which tilts the pulley making it almost in all cases to touch the walls of the pulley.

I am still scratching my head how I paid $800 for these subpar component's quality. However, the things that I am satisfied with are the support here, customer service, and the software.

Ease back the X carriage mounting screws until they are just firm, not fully tight.

Any better?

Cheerio,

X carriage mount

I have not tested it yet, but I did some changes yesterday, mine is fully tight now, I will try releasing a little and then will report it back.

Thanks for the help @Diem

no improvements

I got no improvements after all the mechanical adjustments! the perimeter edges got a little bit better when I change from nearest to aligned, in all edges except where the seams are, which seems normal. Apart from that, I am wondering if the vibrations from the spooler mounted on top or the table could be affecting the quality. Is there a setting in Prusa slicing to reduce the overall speed? does it help to reduce vibrations?

RE: the pictures

After seeing the pictures carefully, there are some slight improvements, the old cube at top, the new at bottom, mostly at edges but I wonder if this is just because I selected the seams aligned vs nearest, notice the X face.

Is there a setting in Prusa slicing to reduce the overall speed? does it help to reduce vibrations?

Yes, but for a quick check you can dial down the speed in the LCD menu. If you have a resonance problem quite a small change will shift the frequency. Try moving the printer to a different surface as a test.

In case your extruder is *just* slipping a little you can tweak the idler pressure: The screw at step 34 on https://help.prusa3d.com/en/guide/5-e-axis-assembly_169235

Cheerio,

I am not sure what my calibration cubes would look like if they were photographed so well and in that light (I would be happy to send you some for comparison purposes if you are in the UK)? You haven't mentioned a PID tune so it would be worth doing this although it probably won't help. Please keep this thread updated with any progress that you make because I am intrigued.

extruder slipping test?

Is there a test to see if the extruder is slipping? mine seems positioned pretty good!

Just try changing by one half-turn, if better try another, if worse go the other way. Repeat until you find your optimum.

Cheerio,

RE: Uneven prints, is this the inconsistent extrusion problem?

Any progress on this?