RE: Underextrusion and noise issues - newly assembled i3MK3S+

@marvin

That is not enough to lubricate. I would recommend that you add a little lube.

--------------------

Chuck H

3D Printer Review Blog

RE: Underextrusion and noise issues - newly assembled i3MK3S+

It's pretty amazing just how much people want to avoid help after they ask for it ... lol.

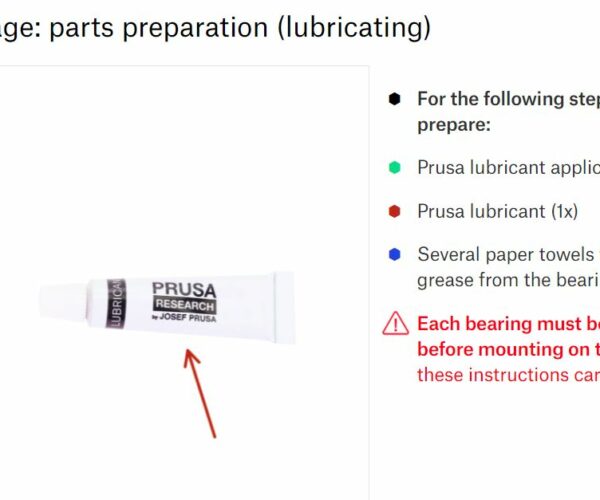

Marvin, read this info from Misumi, please. Then read what Prusa is now telling Mini owners to do that they aren't yet telling Mk3 owners. That triangle with ! mark.

RE: Underextrusion and noise issues - newly assembled i3MK3S+

Thanks again for the input Tim. I will look into setting the idler tension, there is a video by Prusa where they adjust it online, while extruding filament. Probably gonna give that a shot, as the instruction of "screw head should sit flat or up to 1mm below the surface" is useless in my opinion. I already set it on the tighter side during the built, based on the instructions.

I set up the smooth PEI sheet for PLA for the printer and the adhesion is much, much better. Adjusted the live-Z to -1.250 as compared to the -1.605 with the textured sheet, and the test prints stick like glue already. Almost having a tough time getting the calibration prints off of the bed.

What's concerning me the most right now is the drag/friction on the X-axis. Even with fully loosened screws on the backplate, I can barely get the extruder to move under gravity, it only starts at around 60-80 deg. by itself. And even then it moves in fits and starts. The belt test reads 244 for X and 280 for Y, despite the fact that I tightened up the Y-belt in the meantime so the tension gauge sits exactly in between the two limits, while the X-belt tension is still on the lower end of the tension spectrum when tested with the gauge. I also decreased torque on the bolts holding the Y-axis bearing clips a little bit, to try and decrease drag on the axis. Not sure if it did anything though, going by feeling the drag is pretty much the same as before - the motor's pole/step increments make it hard to tell what's going on exactly.

How would you adress the high friction on the X-axis? I already checked the seating of the smooth rods in the printed parts on either side at the Z-axis mounts, visually they are all fine/fully seated. Although I don't have much faith in the tolerances of the printed parts, so crooked/non-parallel smooth rods due to low precision rod seats comes to mind... The bearings are brand new and fully packed with lithium grease, so I doubt that they are the problem. Maybe their seating/positioning in the backplate is bad? Should I try to remove the belt and see if I can locate the issue more precisely then?

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@thomas-d

So you are saying you did clean and grease the bearings? Grease is what reduces drag the most -- it avoids the whole dry rubber seals grabbing the rods thing. Have you tried a few drops of oil and working the extruder back and forth, just as a check?

The bearings can be poorly seated. Taking the rear plate off and ensuring they are properly in their little alcoves is a good idea - especially the lower bearing. They can ride up on the lips that are supposed to hold them in place, and if that happens they are a few degrees off parallel.

The 3 parts making up the X axis can have different sizes, the most common issue is the extruder is smaller that the end brackets. You end up with this ... and the seals wear and leave black goo at either end of the stroke, lower bearing seals go first.

Belt tension has little to do with drag - that is until you get to a point you are scoring the motor and idler bearings, bending motor shafts, that sort of thing. Motor fields can add drag - but, they are part of the system and when the fields aren't active offer little drag. Think about it - X and Y motors and belts are identical, so if it's motor / belt drag, they should be equal, right?.

So it comes down to bearings, lubrication, and just how well they are mounted. That's why fully loosening the extruder back is a good start. If the back is flopping around and the bearings are still dragging ... remove the extruder housing, test each bearing for free movement. Even inserting the rods can cause bearing damage if it isn't done smoothly (the ball bearing retainers are tiny and fragile).

RE: Underextrusion and noise issues - newly assembled i3MK3S+

It's pretty amazing just how much people want to avoid help after they ask for it ... lol.

Marvin, read this info from Misumi, please. Then read what Prusa is now telling Mini owners to do that they aren't yet telling Mk3 owners. That triangle with ! mark.

That's not news to me. I've read that data sheet and even though I must admit that I find it a bit difficult to follow at times I take it to mean that the option of having the bearings lubricated with lithium based grease does not apply the the bearings delivered with our printers. However, Misumi has that as an option, at least for some of it products. A big customer would likely be able to request it for any product. I doubt that Prusa would be nearly big enough to do such a request, but I don't know and the datasheet will not always tell you everything.

What I found interesting was your description of the applied liquid as amber and sticky. That does not match what was on my bearings. So either all bearings aren't delivered with the same grease or you and I have very different ideas about those two words.

Not that it matter, but I can add that I didn't regrease my bearings. I now have some play in the Y-axis and have ordered new bearings that I will clean and grease before mounting.

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@Marvin

While there will always be a question mark because I did not open the packets of bearings you or anyone else who is having bearing issues actually received - the fact remains you are having bearing issues. Does clear and oil-like fit what you received? Colors are fun sometimes. So are descriptions of a film of tacky or sticky or grimy or greasy something. All I know is unless you ordered bearings prelubricated with one of the greases Misumi offers, and anyone can order them that way, they come in preservative. And they look something like this:

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@Marvin

While there will always be a question mark because I did not open the packets of bearings you or anyone else who is having bearing issues actually received - the fact remains you are having bearing issues. Does clear and oil-like fit what you received? Colors are fun sometimes. So are descriptions of a film of tacky or sticky or grimy or greasy something. All I know is unless you ordered bearings prelubricated with one of the greases Misumi offers, and anyone can order them that way, they come in preservative. And they look something like this:

I put all waste back in the the box as I assembled the printer. Turns out that I still have that box hid away in the basement, including the bags that contained the bearings. Clear and oily would be a reasonably good description. Maybe a hint of a yellow tint. It's difficult to say since its just a thin layer, but your picture seems to show something with more color. As I said, it feels and smells very much like the Prusa lubricant.

Regardless of the lubrication, I don't think that's what's caused problems with my bearings. I've found the sound of the Y-axis to be a bit strange from the very beginning. The printer hasn't been running that much and we're not talking any heavy load or speed. Just guessing though.

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@marvin

Let's accept for a moment you got greased bearings. So getting 30 days service life isn't surprising to you? Your experience of short service is quite common with folks who didn't clean and grease - you only need to scan the forums and start counting the complaints.

As a data point: myself and others have seen metal bits fall out in the cleaning solvent when cleaning new 'greased' Prusa bearings.

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@tim I'm not claiming that my bearings were greased, but yes lets put that a side for a moment.

Yes as non expert I find it surprising how much bearing problems there seems to be. Are linear bearings really that much more fragile than rotating bearings? I've seen bearings in cars and cheap power tools that's been running dry or full of dirt and that's been holding up quite a long time. As you say, the forum is full of stories about bad bearings on relatively new printers, could that really be due to bad lubrication? In a few instance sure, and certainly for printers that have seen a lot of use, but I suspect there's more to the story.

Metal chips(?) in new bearings is something I'd only expect in the absolutely cheapest product. Are the Misumi bearings currently delivered by Prusa really that bad? If so there's no wonder that they give up.

As for my Y-axis. The reason I don't think it's the (lack of) grease that's causing issues is that I suspect something has been wrong from the start. Could be something I did wrong during assembly or bad parts. I really don't know and don't make any strong claims either way. Might change opinion once I get replacements and disassemble the printer. Of course, any problem might very well have been amplified by bad lubrication.

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@technical-ted

how to setup two sheet profiles? do you do that in octoprint or on the printer? or in prusaslicer?

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@blackbird11

You do it right on the printer. See this article:

https://help.prusa3d.com/en/article/steel-sheet-profiles_1955/

Ted

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@blackbird11

You'll also most likely need to adjust your Live Z for each sheet/profile.

Ted

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@marvin

Were your bearings clearly marked with the Misumi logo? If not, they were not Misumi bearings. I've never had Misumi bearings wash out debris, only the cheapos Prusa ships. But my personal experience is limited. Misumi does say their preservative is compatible with all grease systems, implication you don't need to clean them, but in the fine print they do say clean then grease.

RE: Underextrusion and noise issues - newly assembled i3MK3S+

@marvin

Were your bearings clearly marked with the Misumi logo? If not, they were not Misumi bearings. I've never had Misumi bearings wash out debris, only the cheapos Prusa ships. But my personal experience is limited. Misumi does say their preservative is compatible with all grease systems, implication you don't need to clean them, but in the fine print they do say clean then grease.

OK, you didn't talk about Misumi, sorry, misunderstood that one. I'm not sure about the markings on my bearings. I'll report back.

RE: Underextrusion and noise issues - newly assembled i3MK3S+

Apologies for being idle for so long, the situation at work has kept me from dedicating time to fixing up the printer. Also huh, where did @Tim-2 go...? Looks like his profile is suddenly inactive, what a shame.

In response to his last post concerning the increased x-axis drag (in case anyone else has input on that): My bearings are all cleaned and fully greased and also I made sure all bearings are properly seated in their cavities in the backplate. So I'm at the end of my wits when it comes to locating the issues. As this thread has deviated quite a bit from the original question, I will open a new one dedicated specifically to troubleshooting the x-axis drag.

Thanks for all the help thus far!