Underextrusion

I'm wondering if a lot of people's issues with adhesion aren't related to, or at least confounded by, under-extrusion. I played with z height, and I was never happy with the way the layers looked. To get good coverage the layer would be too thin. I was getting edge peeling too as prints passed about 1mm. I started to think that the print was under extruding. I started bumping by 0.1 or 0.05 extrusion.

That way I could move the z a bit higher and maintain god coverage, and the edges started to stay put better.

Problem is that it looks like I needed to bump it to 1.2 to 1.25. At least for the thinner test prints I'm making (15 x60 mm plaques with circles and posts in them).

Having just put my Mk3 together, that small set screw for the extruder is a joke. I guess it could be slipping, but it is kind of odd that it was so consistent.

I've had a fair amount of experience with Printrbots, and calibrating the extruder was a key performance driver. I'm surprised that thesubject rarely gets talked about here.

Anyone calibrating their Mk3 extruders?

ETA:

I think I need to rejuvenate my PC board with acetone and that 1.2 might be a bit much. Probably closer to 1.15 or less.

Re: Underextrusion

that seems pretty unusual to have to bump by 20% with a direct drive. I've never, ever been more than 1 or 2% off.

Re: Underextrusion

I'm guessing that based on your screen name you are in Denver or at least at altitude. I've been experiencing the same problem and was curious if altitude was playing a role in the equation as I'm in Denver. Anyone have information if there are differentials for settings based on altitude increases?

Re: Underextrusion

I'm guessing that based on your screen name you are in Denver or at least at altitude. I've been experiencing the same problem and was curious if altitude was playing a role in the equation as I'm in Denver. Anyone have information if there are differentials for settings based on altitude increases?

I think that moisture would be the main issue and its effect on filament and maybe heat coming off the print bed (much less of an effect). I don't think that the altitude would effect much. Lower BPs would be offset with lower humidity, I'd think.

I did some soap&water and then acetone cleaning and I'm still not getting great adhesion with the included PLA.

I want to calibrate the extruder, but I'm struggling to find the right software to send commands directly to the extruder to get a measurement done on the filament extrusion.

Re: Underextrusion

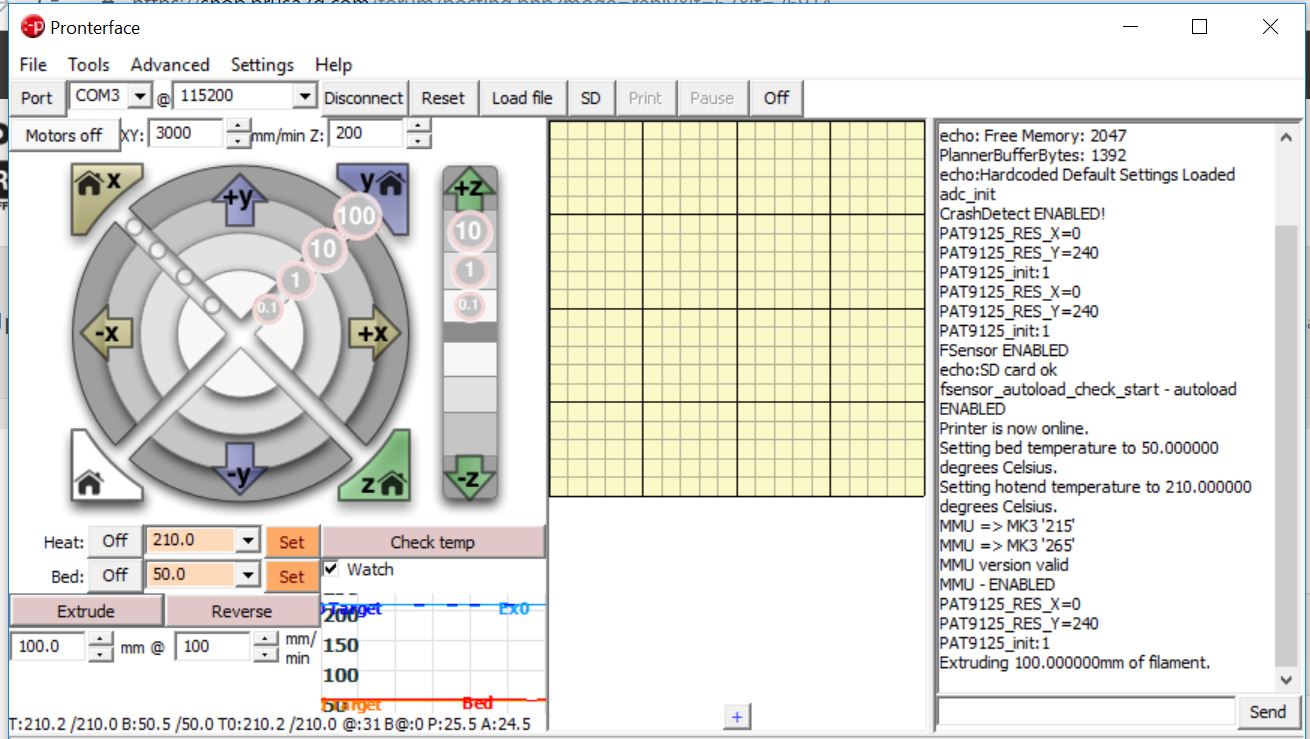

Use Prontaprint, which should be in the Prusa menu on your PC...

I will assume that you already have filament loaded, if not, please load a suitable filament, preferably a light colour so that it is easy to mark it, and see the mark.

Connect your PC to your printer using a USB cable,

make sure the internal Raspberry pi interface is turned off,

open Prontaprint,

set the baud rate to 115200,

select the appropriate Com port,

click on connect

wait for the printer to respond,

you should start seeing information in the right hand window

put a mark on your filament 120mm above the top of the extruder.

click on the 'Heat' drop down box, and choose the correct temperature for your chosen filament, ( I have chosen 210Centigrade)

Click on 'SET' and your extruder should begin to heat up... whilst you are waiting ensure that your extruder is well above the build plate so that there is somewhere for the extruded filament to go to...

If not click on the '+10' circle under the '+Z' arrow, the extruder should raise 10mm per click

while the extruder is heating look for the extrude button, underneath this is a selection box which probably shows 10mm, reset this to 100mm

when the extruder has reached proper temperature (visible on the temperature graph in prontaprint, and on the LCD Display, click on the extrude button

assuming all is well, the extruder will feed 100mm of filament into the top of the extruder, as the extruder probably has a 0.4mm nozzle fitted at the bottom, you will get a lot more than 100mm length of extrusion at the bottom, the volume of material extruded should equate to the volume of a 100mm tall cylinder of 1.75mm diameter. when the extruder has finished extruding, measure the distance from the top of the extruder, to the mark that you made earlier,

if it is 20mm, you are spot on,

if it is less than 20mm you are over extruding,

if it is more than 20mm you are under extruding

If you need to revise the extruder calibration, you will need to find the relevant thread and follow that procedure, (I have never adjusted my Mk1, mk2 , Mk2 MMUv1, mk3 or Mk3 MMUv2 extruders, from standard)

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Underextrusion

Thanks, about 3% underextrusion. Printing out some test boxes and such. Seem to be getting better adhesion. Also did a fair amount of soap and water followed by acetone wiping with some short 'soaks' with paper towels.

I printed a square with on perimeter. What should the width of that wall be with a .4 nozzle? I'm getting about .44 thickness. One wall is thicker, about 0.5+0.05

Re: Underextrusion

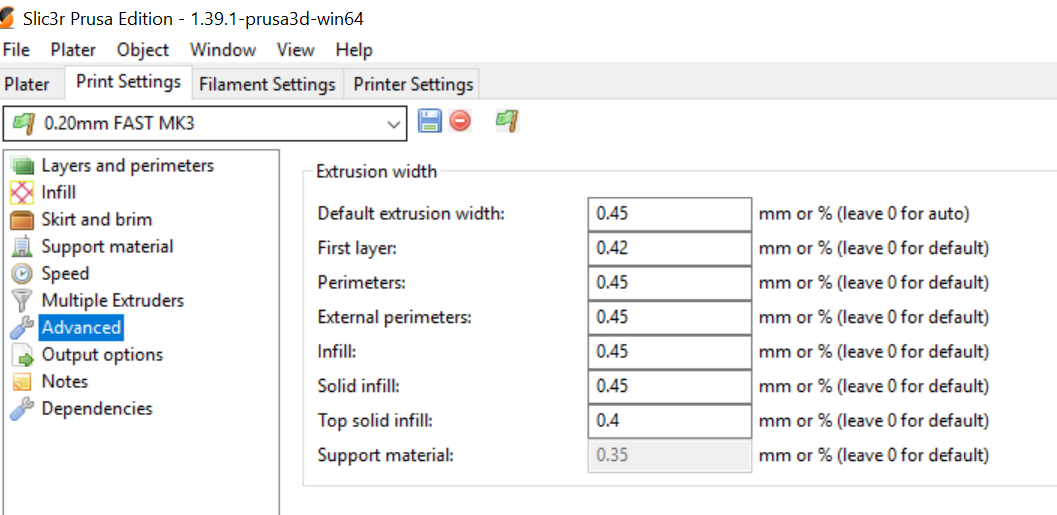

the expected wall thickness depends upon the Slicer settings

see below

as you will see, the perimeters are set for 0.45mm extrusion width

so if you are getting 0.44 you are pretty close!

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Underextrusion

Can I also suggest setting the extruder speed to 50 mm/min as this is more like normal printing speed (100%) with a 0.4 nozzle because if your extruder tension is a bit on the low side, you may slip at 200% extrusion and think you have an under extrusion problem.

Although I believe a correctly adjusted extruder should be able to manage faster than this and should repeatably extrude 100mm even with a speed of 250 mm/min, but you are better off aiming for reliable extrusion up to 100mm to get a good balance between grip on the filament and loading on the motor / bearings.

Also more load = more current = more heat in the motor = more heat in the extruder gears conducted from the motor, I see people putting fans on their extruder motor and stating how hot it gets yet mine only gets warm after 24 hrs continuous printing.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Underextrusion

I'm guessing that based on your screen name you are in Denver or at least at altitude. I've been experiencing the same problem and was curious if altitude was playing a role in the equation as I'm in Denver. Anyone have information if there are differentials for settings based on altitude increases?

I've got a freshly self-assembled MK3 and live in the Denver area.

I did a extrusion measurement test, and to the accuracy of my markings, it was extruding exactly the amount of filament specified - marked 100mm, extruded 100mm.