Textured plate

Just tried the textured plate with PETG for the first time. Ran a first layer calibration. Basically performed like a non-stick frying pan. The filament was just pulled along by the extruder.

Reran it on the smooth plate, worked fine.

Is there anything "special" I need to do to use the texture plate?

RE: Textured plate

The textured sheet is (roughly) 0.300 thinner than the smooth sheet. Does that about agree with what your new live z value for the textured sheet came out to be?

RE: Textured plate

Nothing special; just a z adjustment and patience. For some reason this sheet is more sensitive than the PEI.

RE: Textured plate

@vintagepc

I did adjust it but not by that much! about 0.05.

I have started the print on the PEI sheet and its looking fine so when that finally finishes (not a small print!) I'll play again with the textured sheet.

RE: Textured plate

I've found that the textured sheet needs to have the Z lower, by quite a bit, to print properly.

It also seems to be more sensitive to dirt and such things as finger smears than the smooth sheet. It needs to be Really Most Sincerely clean to work.

I've also found that PLA is the most tricky to print on the textured sheet. The most tricky are small PLA parts and PLA parts that need supports.

There's also anecdotal evidence here on the forum that there are 'good' and 'bad' textured sheets, possibly having to do with the supplier. Mine has the code of WA-15 (upper right corner) and I apparently have one of the 'good' ones.

There's also anecdotal evidence that some of them have a coating that's uneven across the surface, and switching to the 7x7 (I would suggest 7x7 with 5 samples) bed auto-level is the work-around for that.

RE: Textured plate

So yesterday I also tried to print some smaller PLA parts on the textured sheet and it didn't work.

I've cleaned the thing thoroughly with 99% IPA, I've adjusted the Z axis and even re-calibrated it but to no avail.

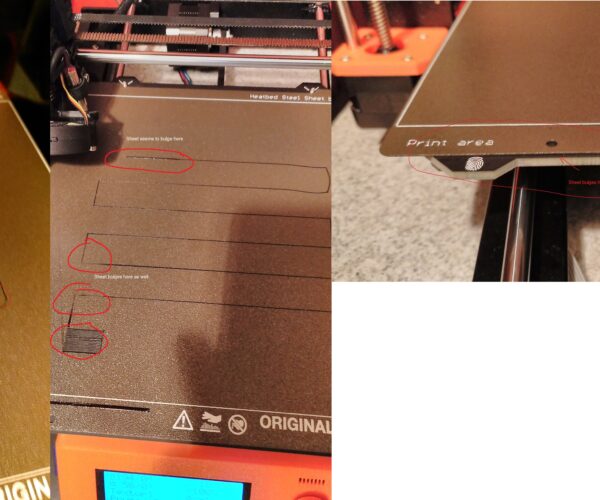

The sheet (mine has the code TF-26) is uneven across the whole sheet, it bulges up at some spots which causes the nozzle to be to close to the sheet which causes the material to be overextruded so it creates blobs of material, where as there are spots where the material can't stick because the sheet seems to be dented on these spots. I think the powder coating is causing these uneven spots, though in the last picture you can see that the lower left corner is actually bulging up, so it might even be the sheet itself.

IMHO my sheet has been manufactured improperly and I asked the support for a replacement as this sheet is not within any margin of error. I think Prusa's QA should enforce some stricter quality requirements for their testing process.

My smooth PEI sheet for example is perfectly level, there is one spot where both, the textured and smooth sheets, are a little bulged up (second image left corner where the printed line gets thinner, happens with both sheets), but I can still print perfectly fine on the smooth sheet without issues whereas the textured sheet screws up every print, except when I put it into the top-right corner of the sheet (first picture).

RE: Textured plate

Are you using the 7x7 bed leveling, or the default 3x3?

If it is misbehaving on the 7x7, I would suggest going back to support, being assertive if needed, and getting a replacement. You appear to have documented the issue well.

RE: Textured plate

Clean sheet with dish soap, and dry after cleaning, no alcohol needed.

Adjust first layer calibration.

If you switch pla to petg or petg to pla, clean again with dish soap.

RE: Textured plate

I haven't tried 7x7 bed leveling yet, I'll try later. I expected the sheet to be as even as the smooth sheet but I guess it often isn't.

Can somebody explain me on a more "scientific" level why I should prefer cleaning with dish soap over 99% IPA?

I've read it on many threads but nobody really explained why dish soap cleaning would improve adhesiveness. Is it that the dish soap leaves some residue that increases adhesiveness?

RE: Textured plate

@shawly

I'll take a shot at that question:)

The main thing that stops adhesion is oil/grease. The natural skin oils from your fingers for example when you touch the sheet.

IPA dissolves the oils into suspension and in effect moves then around. Unless you use LOTS of IPA what you are actually doing is making a thinner more even layer of oils on the plate.

Dish soaps (dawn/fairy etc) are surfectants (not sure I spelt that correctly). These are designed to surround the oils and greases and so when you rinse it away it carries the oils away too. This leaves a cleaner surface behind. You are basically using far more volume using hot water than you would ever use with IPA too, unless you buy it by the drum 🙂

The main objection to using dish soaps and HOT water rinsing are the fact that the print sheets are steel under the PEI coatings. The textured particularly when looked at under a microscope clearly has steel in the bottom of the texture. Steel plus water can equal rusting. However if you are careful about drying the sheet thoroughly and immediately (clean paper towels and then baking it on your heat bed) then rust forming is not an issue.

There are also sometimes residues from filaments (manufacturer additives) that IPA has difficulty breaking down and cleaning.

If you are careful (some would say obsessive) in only touching the bed by the edges you can go quite a few prints between cleanings.

RE: Textured plate

A very satisfying explanation, makes sense to me, thank you!

RE: Textured plate

@neophyl

You can see the effect when cleaning the PEI sheet as, if its cleaned properly, then when rinsing virtually all the water runs off leaving very little drying required. Had good success with this sheet even printing small parts one after the other only cleaning a few times.

Still not tried the textured sheet again as busy turning out parts but will do when I get a moment.

Glad to see the topic spurred on a good conversation. 🙂

RE: Textured plate

I think we're probably going to have to agree to disagree whether water-based solvents or organic solvents are better for cleaning the plates.

However, the point still stands that the plate must be absolutely and 'really most sincerely' clean for a print to stick. It also appears to be 'settled law' that the oils from human fingerprints are the most common impediment to a print properly sticking.

I do believe, however, that there are some cases where a jump-to-conclusion has pointed the finger at an alleged lack of cleanliness as the cause of a difficult-to-stick case where other factors were more significant.

There's also evidence that some (how many? not sure), but definitely not all, of the textured sheets from Prusa and other vendors are defective to the point that consistent reliable prints are not possible. I think what was most revealing along this line were two recent reports of the coating being inconsistent across the plates. I know one was worked-around by switching to 7x7 bed leveling.

Yes, I agree that this is some very good conversation on the topic.

RE: Textured plate

Oh I agree about the differences in textured plates. Never said otherwise, I was just answering the question about the differences in cleaning with IPA/detergent.

I have 2 prusa smooth sheets and an off brand smooth sheet and a single prusa brand textured sheet. Its absolute garbage as far as getting pla to stick to it. And I know how to clean a sheet and set the z height offset properly. I also believe the users that state that they 'get better over time' with use. I just cant be bothered to spend the time or energy to 'season' the sheet that way. I haven't needed the texture on a PLA print as yet. I'll fix it when I need to. Which possibly may be never 🙂

Inconsistent thickness of the coating I can see, the coatings are sprayed on and then baked like most power coating type operations I think, so I can see there being variations due to the process used. And the z levelling is only going to be of limited use as that detects the steel below the coating, if the steel is of even thickness then the Pinda isn't going to pick up that the non metallic pei coating is different. Which is why you can adjust for one spot and other spots just don't stick as they are lower.

Basically I just never recommend a textured sheet as a first sheet to anyone who asks.

If I had to try and use mine (ie the fixing I mentioned before) the first thing I will do is to very lightly abrade the surface with a poliblock (poliblock is a rubber compound with very fine particles in that is used to clean electrical contacts, basically very very fine sandpaper equivalent). Giving any high spots a bit more attention. If that works then all good.

One other thing to try is to over-extrude the first layer only, giving more plastic to push into the lower areas. This would probably need the elephants foot compensation tweaking to match too. Ah one day i'll get round to trying it again, but that day is not today.

RE: Textured plate

Oh wow, I found the issue, it's actually a little awkward haha.

The one U-bolt on the lower left, which holds the ball bearings for the Y-axis were tightened unevenly, so one side of the U-bolt actually pushed the heatbed slightly upwards and this caused the unevenness on my pictures since the whole bed was warped slightly.

After releasing the locknut and turning the other locknut so that the threadings of the U-bolt are on equal height, remounting the bed and recalibrating XYZ I finally got a perfect first layer calibration with the textured sheet. Even without using 7x7x7 mesh bed leveling.

So to everyone with similar issues, check the U-bolts on your Y-axis carriage. Make sure when you follow the Y-axis assembly ( https://help.prusa3d.com/en/guide/2-y-axis-assembly_25488#26680 ), that you actually follow the manual properly and only turn the nuts 90 degrees instead of turning them until they are hand-tight like me 🙄.

RE: Textured plate

Very good find! Thanks. Probably a good sheet in this case.