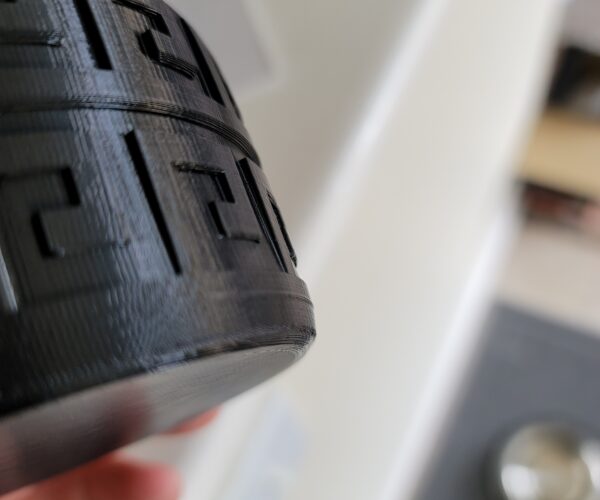

Surface Quality Issues - Rounded surface above build plate

Hi all,

I have been running into an issue with rough/poor quality surface finish on the underside of some round pots I'm working on. I have tried both with supports and without as well as using variable layer heights to make the region where the tapering occurs to have a substantially lower layer height (0.1mm compared to 0.2mm for the rest of the print) and it doesn't seem to make much of a difference. The only improvement was to reduce how much the lower section edge is rounded in favor of a nearly vertical wall but I would prefer to avoid this route if I can since I like the overall appearance of the rounded pots a lot better.

Any help would be greatly appreciated!

You can't print in mid air and at the start of a curved bottom there isn't room for support ... so this is normal for all FDM printing.

Substitute a chamfer or invert the object and print upside down.

Cheerio,

RE:

You can try one or more of these changes in the problem area (using modifiers). Increase your extrusion width to 200% of your nozzle size, slow the speed and lower the temperature. If you want, you can upload your ZIPPED .3MF file. (It needs to be ZIPPED or the forum server won't attach it) for more specific suggestions.

Mk3S+,SL1S