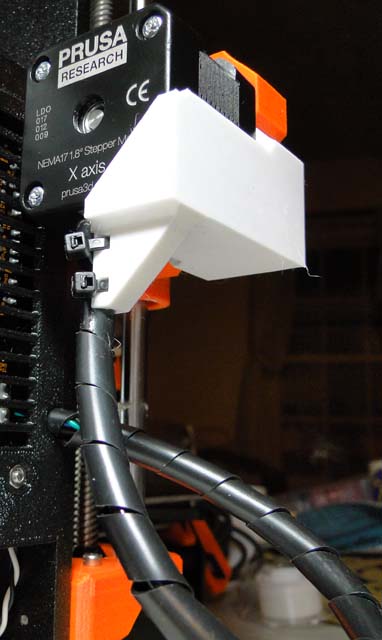

Spiral wrap on X axis motor

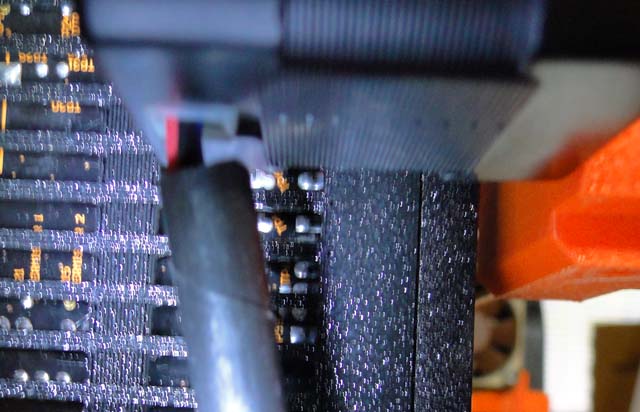

After I got the printer assembled and tested, I came to the conclusion that the spiral wrap on the wiring to the X axis motor is unnecessary and in fact harmful.

Normally, spiral wrap is a good thing because it prevents wires from being bent back and forth with a very small radius. Such bending leads to wire fatigue and failure. However, in this case, the effect is perversely exactly the opposite of the intended one. The spiral wrap does indeed stiffen the wires where it covers them, but unfortunately the spiral wrap is not anchored to the motor. Thus, there is a small, unsupported millimeter or two of wire that ends up absorbing most of the bending - exactly the formula for fatigue failure. As a result of this observation, I have completely removed the spiral wrap from my X-axis motor cable. This allows the bending to be spread out over a greater length of the wires, reducing the probability of fatigue failure.

Re: Spiral wrap on X axis motor

I made a plate with a tapered tongue out of 98a flexible TPU that i attached to the back of the X motor. That anchors the end of the cable wrap and provides strain relief.

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Spiral wrap on X axis motor

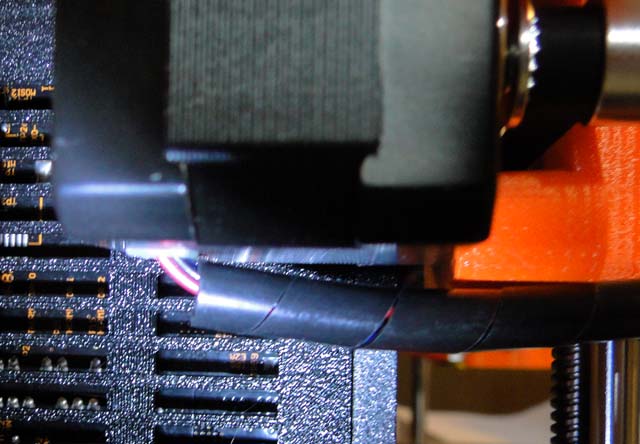

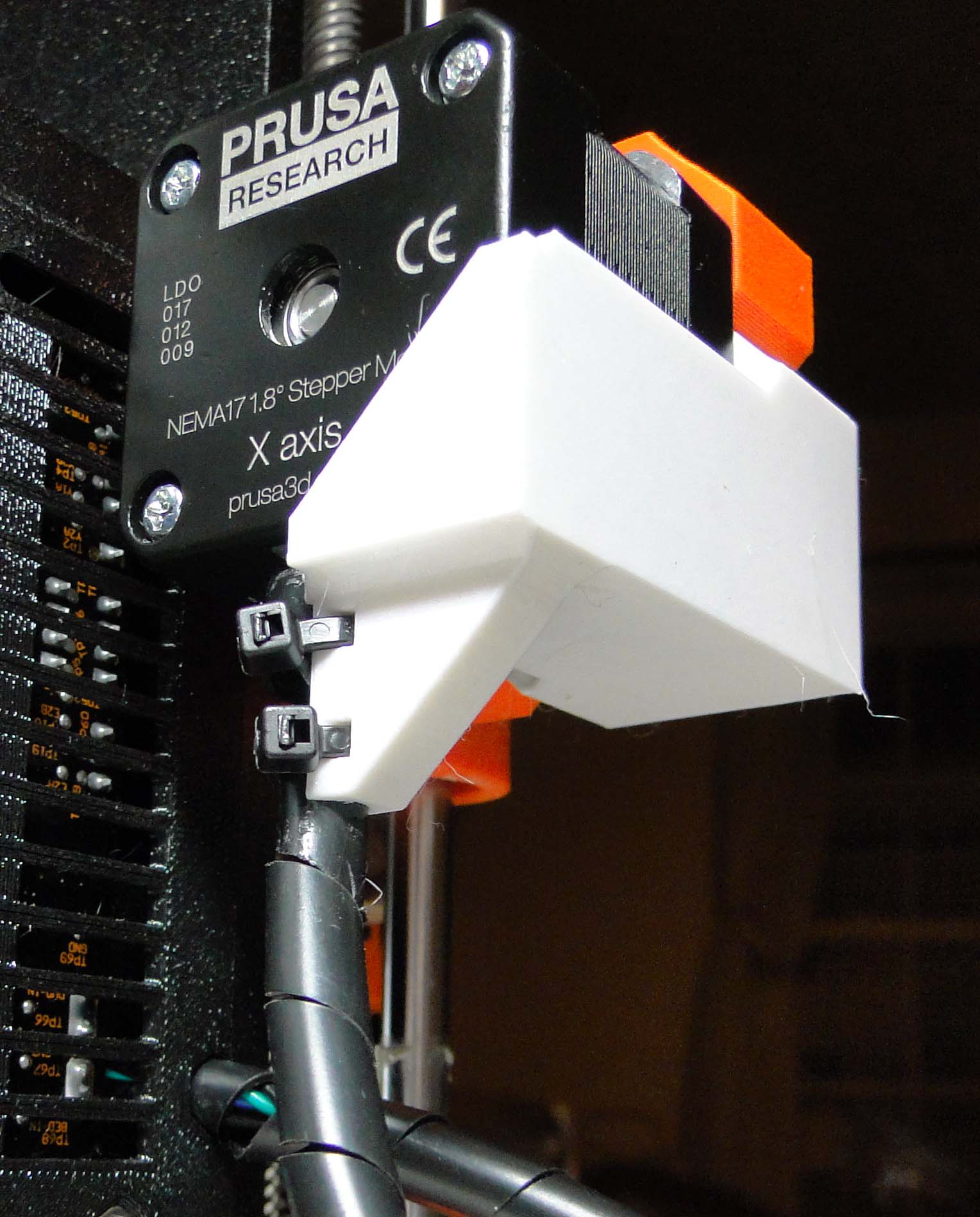

I took Wapameepto's suggestion, but as an exercise I designed my own fixture similar to the one on Thingiverse. It can be printed with no support. It turned out to be a really tight fit onto the motor, but it worked. Now the motor cable is supported at the motor end by this fixture, and it travels to the port in the electronics enclosure inside spiral wrap additionally stiffened with a length of 3mm PET filament, just like the other cables on the printer.

Re: Spiral wrap on X axis motor

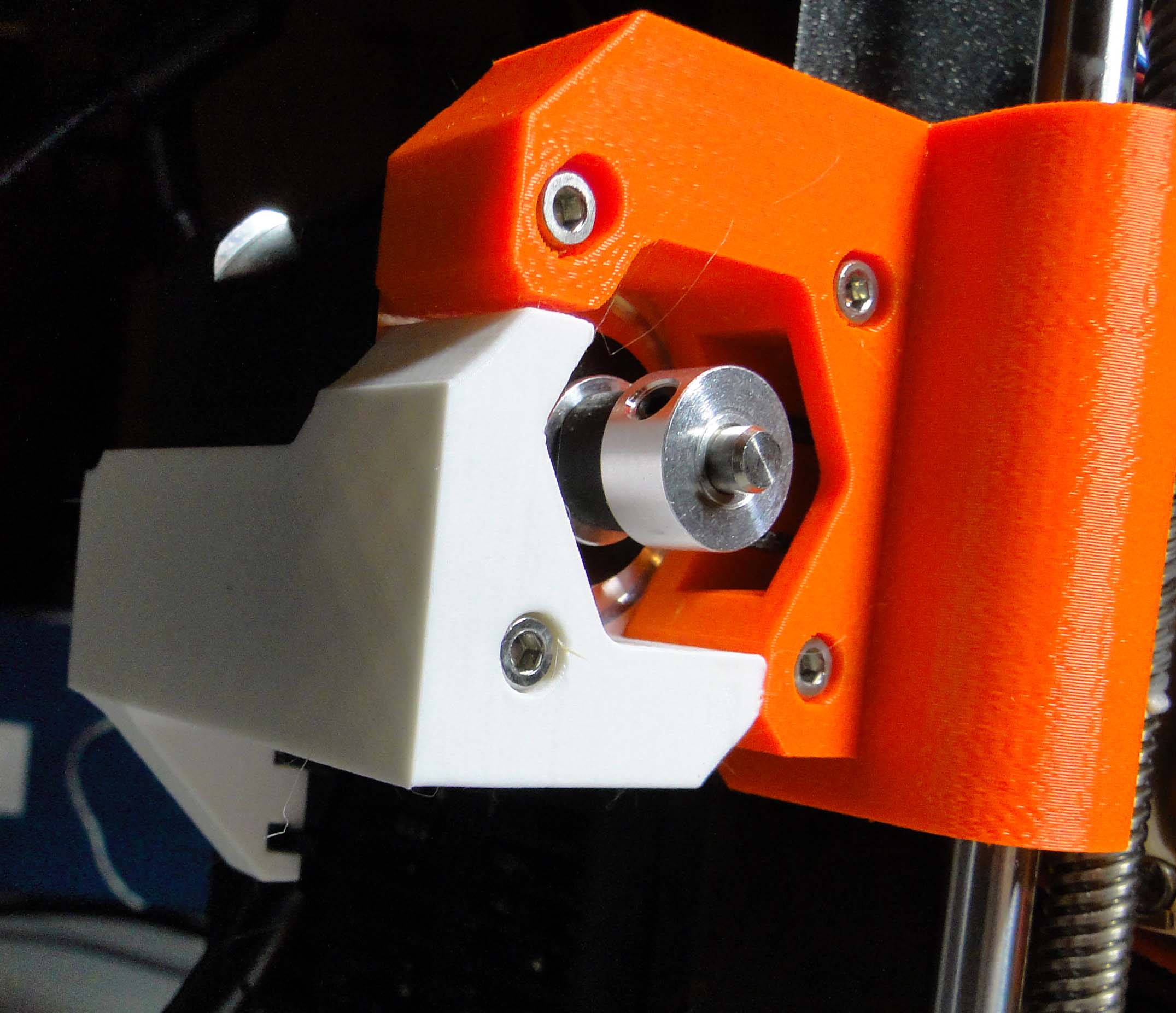

Jakub Dolezal asked for pictures. Although this strain relief is attached with only one screw, it does have a "nub" on the other end of the motor that engages with the corresponding motor screw. And the whole thing is a very tight fit on the motor, so it's not going anywhere. I designed the front just to match the aesthetic of the Prusa parts.

Re: Spiral wrap on X axis motor

Nice effort!

I do prefer the Thingiverse item for a couple reasons... Since it holds the cable out the back at an angle, the cable wants to form a nice loop that seems to distribute the flex consistently along the cable over the z-travel distance, instead of just at the (lack of) attachment to the stepper.

I feel like the 90 degree attachment will still want to concentrate strain at the mount, only now it’s a couple cm lower where the coil meets the zip tie, which is still a huge improvement over the coil alone. Your part will be better at the top of the Z-range, but very few of my prints make it up there, so optimizing for the bottom seems like the better call.

Aesthetically, it looks great from the front. The bottom corner is a bit of an eyesore though. Try making a chamfer to match the Prusa parts. You may be able to cut the size a bit too. Still, a very nice part.

When someone asks you if you're a god, you say, "YES!"

Re: Spiral wrap on X axis motor

Thanks for the comments. This is one of the first parts I printed on the MK3. You are right about the sharp corner. If anyone ever asks for the design, I'll tweak that.

Actually, as you can see in the picture, the cable forms a nice loop when the axis is near the bed.

Re: Spiral wrap on X axis motor

Hi Jay,

thanks for sharing 😉

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: Spiral wrap on X axis motor

Normally, spiral wrap is a good thing because it prevents wires from being bent back and forth with a very small radius. Such bending leads to wire fatigue and failure

Just for clarification, spiral wrap is not used for strain relief. It is used to prevent abrasion to the enclosed material.

Strain relief is an entirely different category in IPC620 specifications. It's especially useful/required near solder joints and crimped connections.

That being said, the cables (as shown in the pictures) would absolutely benefit from the strain relief added by the printed mounts. Nice catch.

Re: Spiral wrap on X axis motor

Hi,

I think this is a useful solution. Would you consider sharing a stl or gcode file with me?

With kind regards

Bengt Wannerheim

Re: Spiral wrap on X axis motor

I find this very interesting; with over 300 Mk3s running 24-7 you would think this is exactly the sort of fatigue posable fault they would have rectified with a rolling update like the raspberry pi 0 mod to the ensi case last week

Re: Spiral wrap on X axis motor

Fixing problems that don't exist is the best.🙂

Re: Spiral wrap on X axis motor

I have now published the file.

https://www.thingiverse.com/thing:3149251