Request Recommendations - Resolving Failed Print Aftermath

I am not new to 3d printing, however I am new to Prusa. This is my third 3d printer.

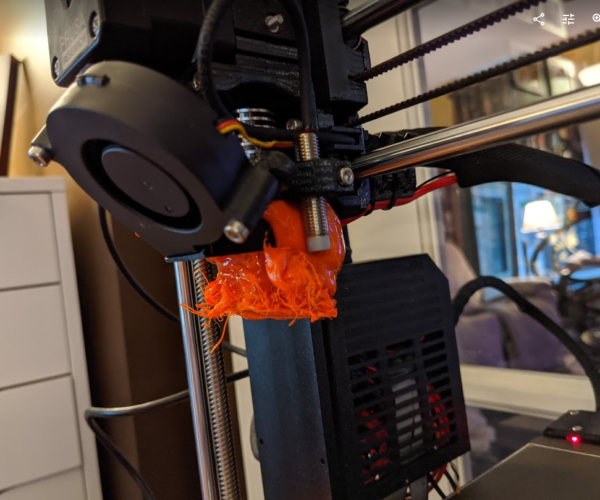

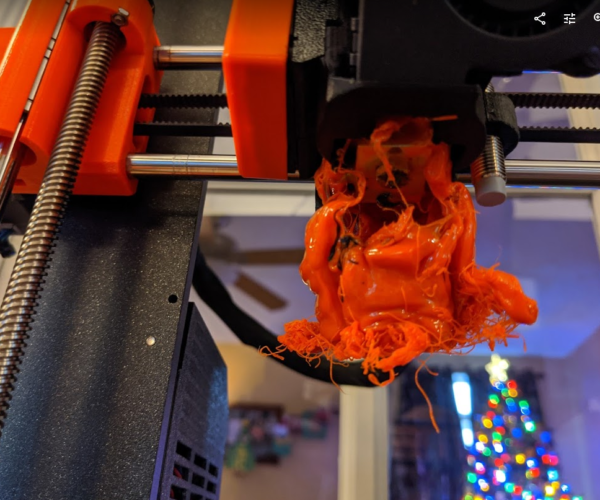

This morning I woke up to six hours worth of PETG stuck to the print head. Prints fail, no big deal, I'm not in a panic - but this is the first time this has happened to me on a Prusa and I'm wondering what the forum's recommendations are on resolving this.

I started by heating the nozzle and I let it sit for a while. That enabled me to gently pull the larger body away from the print head - but there is still a lot of adhesion. I'm done pulling on it, it's going to need to be dealt with more surgically. It seems possible that the failed print is all but welded to parts of the print head at this point.

I plan to take apart the print head when I get home from work and clean this up properly - but here is my biggest question:

If I get in there and find that my fears are correct and too much of the PETG is stuck to 3d printed parts of the assembly, at what point should I bail out on trying to clean it up and just reprint those assembly parts? I've never used a printer that relied this heavily on 3d printed components and I'm trying to gauge if this is one of those times I should make use of this "feature".

I should also note that the strongest material I'm capable of printing right now is PETG, I don't have anything rigged up for ASA/ASB.

Thanks for looking at my post -

RE: Request Recommendations - Resolving Failed Print Aftermath

Are any of the 3D printed parts damaged? In your 2nd picture, it looks messy but mostly from PETG stuck around the hotend. If you can get it clear enough to open the extruder up and remove the hotend, you may be able to clean it up just by heating it up and carefully pulling away filament with a toothpick or strip of cardboard. I had a less disastrous result with PETG and was pleasantly surprised that a bit of cleanup did the trick.

Be very careful around the thermistor and heater cartridge wires. If those break, you may be looking at replacement. In my case, my (original) stripped out heater block had lots of baked on and caramelized filament entombing the heatbreak, heater cartridge and thermistor, so I wound up replacing most of the hotend, although I was later able to recover the heatbreak. I recommend keeping spares of most of a hotend available on hand. Also consider using a silicone sock to (hopefully) keep stuff off the block and delicate wires.

Good luck with it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Request Recommendations - Resolving Failed Print Aftermath

@bobstro

Thanks again for your sage advice. I was studying the photo more and I hope you are right and I will be able to take care of the remaining PETG cleanly, because I am concerned about the wiring and the more important components.

My first thought when I saw this mess was "I should have ordered that thermal sock"! Something black did melt into the orange, it's difficult to see in the photo. I think it is possibly part of the cooling fan shroud. That's when I decided to stop trying to ease the melted filament away and take the thing apart to finish nicely (I'll cut away the large part of the blob with cutters).

I hope my next post is to announce that it all worked out -