Prints failing often

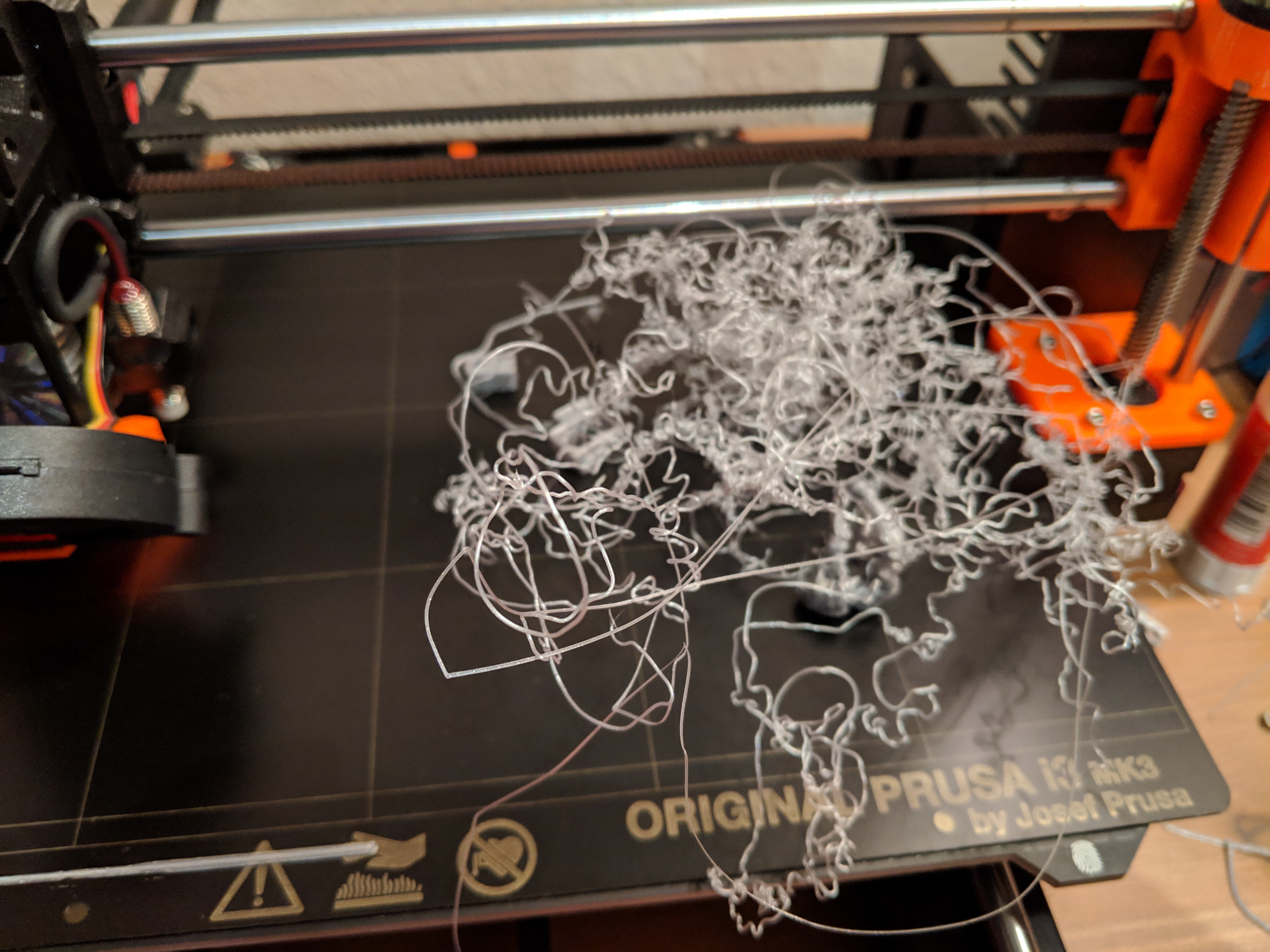

I got a MK3 a few months ago. From the beginning it has had problems on most of the prints (MK3 smooth, Prusa Slic3r, default 0.15mm settings). I have not printed on it much as I have not had much time to play with it and deal with the problems. The first problem was that from the beginning I have had to turn off collision detection on every print as otherwise it would stop printing every five to ten minutes even though nothing was wrong as far as I could see. About 25% of the prints since then have been perfect with no problems (Castle and Frog from original card and 3d Benchy). However, most prints fail. Some fail on the first layer and get stuck to the nozzle, some go perfect and then halfway the printer starts making a mess and puts out spaghetti. Some get stuck to the nozzle and get moved around the bed. I have tried everything I can think of but it is still very unreliable and there is no one issue. I have dropped the speed to 20% with no effect other than the printer taking longer. I make sure that the hot end and the bed are both perfectly clean. I run the XYZ calibration between every few prints. I have moved the printer onto the floor to make sure that a shaky table is not messing it up.

I am not sure what to do to improve it as I would love to get consistently good prints. I can get photos if you need.

Re: Prints failing often

sounds like you may have several issues, but may need to work on them one at a time.

pics would be helpful.

Re: Prints failing often

I would first make sure the hotend is in correctly. (there is a spot that should be flush on the bottom of the heatsink). then check the belts.

can your printer lay down the first layer on the whole bed?

I have a Prusa,therefore I research.

Re: Prints failing often

Start off by decreasing your build plate with dish wash detergent and water solution. I take my mk3 build plate to the kitchen sink. Ute a clean paper towel to rub Dawn or fairy liquid or similar into the surface. Dilute with water rub in really well. And wash off with clean water

Then dry with a fresh paper towel.

DO NOT GET FINGER PRINTS ON THE BUILD PLATE WHEN PRINTING PLS.. ..

Print the first layer of the prusa logo. And let us see a picture of the first layer

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Prints failing often

Thank you for your responses. I have tried to fix the problem. I do not know what to check on the hotend as it looks the same as in the Build Guide.

I first cleaned the build plate with dish soap and warm water and made sure to only touch the edges.

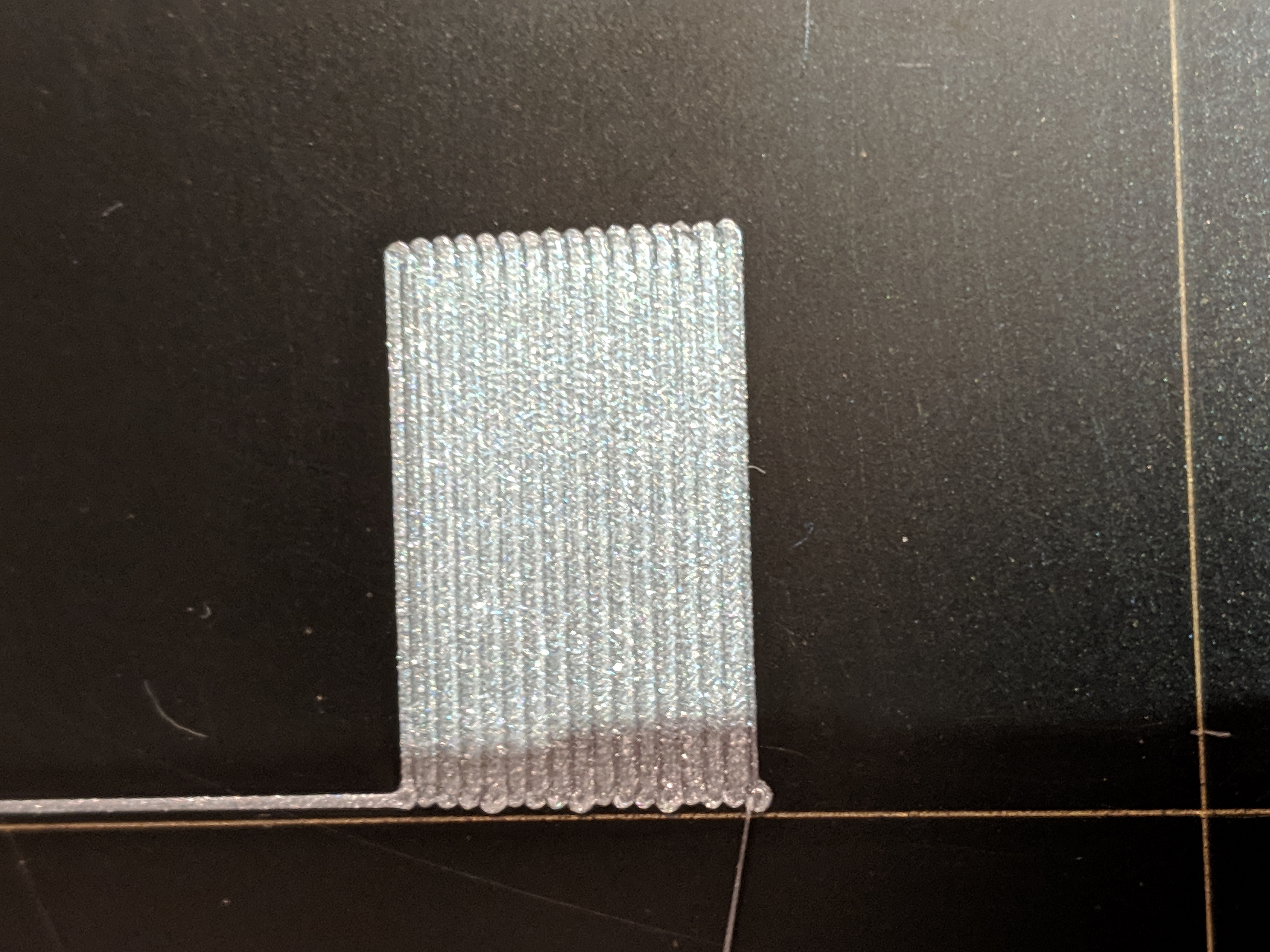

I printed out the first layer calibration.

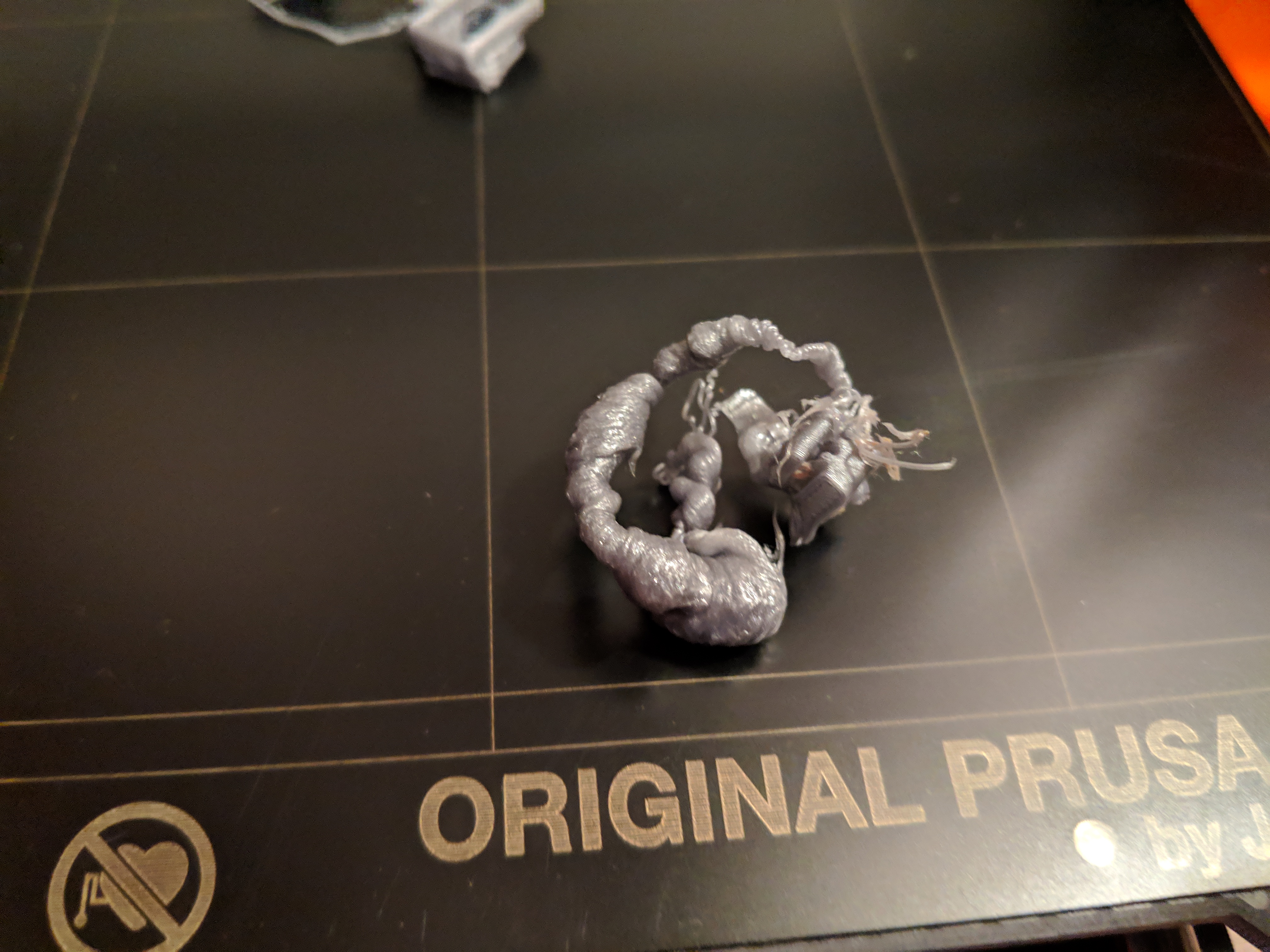

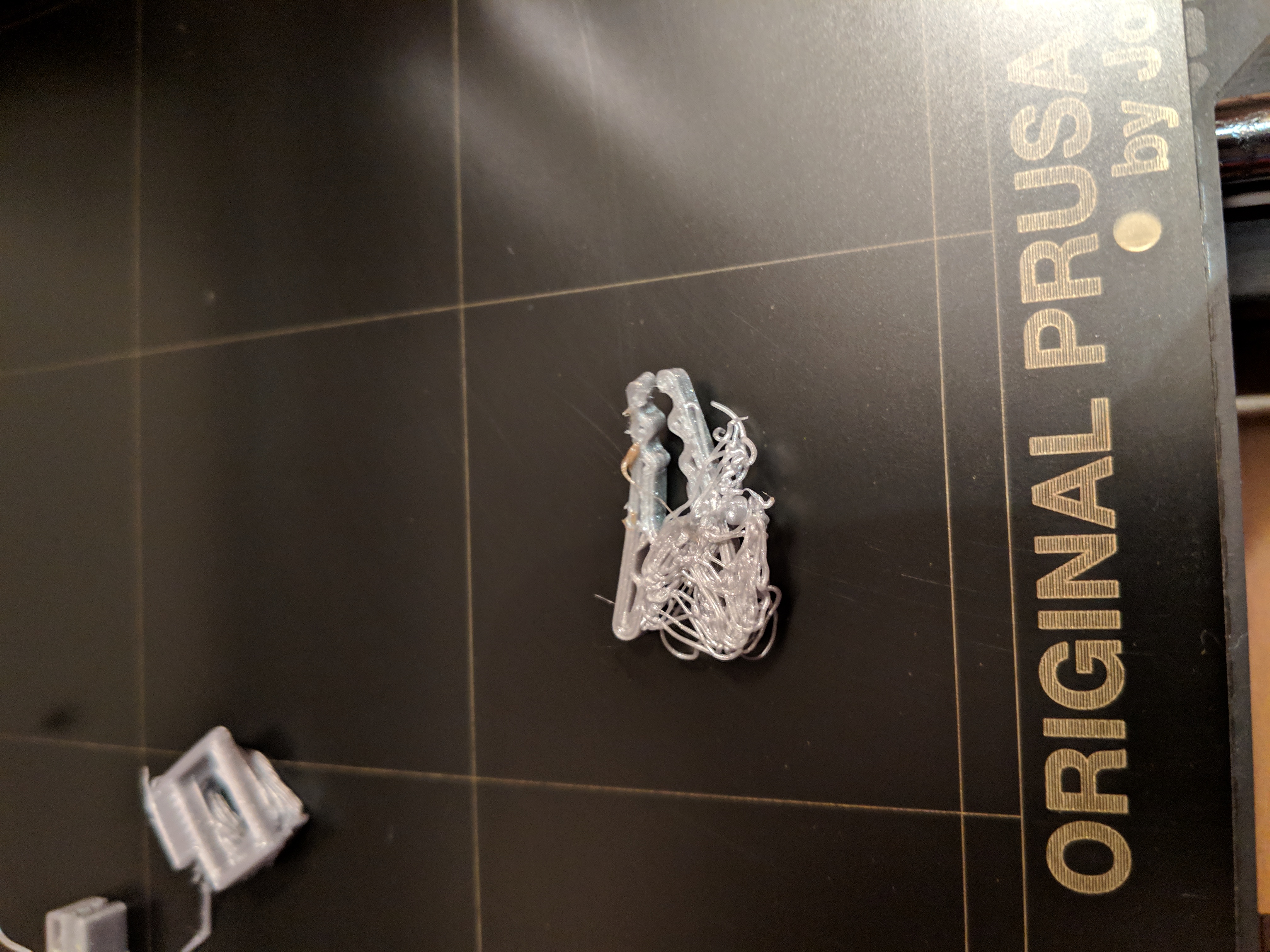

Each of the shown prints had the bed cleaned in between.

This mess was stuck to the nozzle.

This piece had three on the plate and the other two came out perfect.

Re: Prints failing often

I am not sure what to do to improve it as I would love to get consistently good prints. I can get photos if you need.

Sounds like you just need to get some 100% pure acetone and do a bed refresh...alcohol will remove contaminants but to return the surface to "like new" it's best to give it a good solid wipe with acetone.

Try that, and also, you should never need to re-run Calibrate XYZ unless your machine has undergone some mechanical adjustments, "Calibrate Z" however can be used after moving the machine - or just whenever - to ensure your X Axis is properly aligned with the frame, which is always best.