Re: Print bed low in center

Lower the live Z a little bit. It should be a negative number like -0.68 and maybe you can try -0.70

It will help others if you can give some history - is this the first print? what have you tried so far?

within reason - the mesh bed levelling routine that runs at the beginning of every print will account for small imperfections in flatness. It is very unlikely that the rods are bent.

Re: Print bed low in center

The Z is not the problem. It adheres fine around the edges, and poorly in the center. The Z is already at -1.50.

This isn't the first thing I've printed; I've had successful prints, but anytime the print needs to start in the center, it fails.

Re: Print bed low in center

With live Z at -1.50 it indicates the Pinda sensor is not at the correct height ** edited from my way-too-early-in the morning ** post. I suggest studying this area and possibly change the height. mine has been working really well at ~ -0.7 offset which is where it was when I built it.

Re: Print bed low in center

once you have adjusted your pinda, if the low centre issue persists, Try bed level correction you can use positive numbers to reduce the squish around the edges, relative to the centre.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Print bed low in center

OK, should I move the probe up or down?

Re: Print bed low in center

Hi William,

as I understand the situation, you currently have all of the bed level setting at 0

when you do your concentric square print, the squish is good all round the outside of the heatbed but there is insufficient squish in the centre

this leads you to believe there is a dip in the centre of the bed

there are nine screws holding the bed down, each should have a spacer between the heatbed and the Y axis frame, have you checked that these are all in position (if the middle spacer was missing, you could get the issue you are seeing) check and correct if necessary.

if the middle is still too low, changing the front, left, right and back 'bed level adjustments' to say 20 (positive number)

will reduce the squish around the outside of the heatbed, then,

if you then adjust live Z, to restore the squish around the outside (make Live Z number, more negative)

this will also increase the squish in the middle of the heatbed.

if there is still insufficient squish in the middle, re adjust the bed level adjustments to say 30 and again adjust your Live Z value

geek adjusting until satisfied, or until you run out of adjustment

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Print bed low in center

Would it make sense to try putting one of the spare nylon/teflon (I don't know which--I've seen them called either) washers over or under that center spacer?

That's "MISTER Old Fart" to you!

Re: Print bed low in center

Before making any mechanical change, you should do two things.

1. Adjust the Z level (I think it looks too high)

2. Clean the bed with detergent and water

Bear MK3 with Bondtech extruder

Re: Print bed low in center

Hi William,

as I understand the situation, you currently have all of the bed level setting at 0

when you do your concentric square print, the squish is good all round the outside of the heatbed but there is insufficient squish in the centre

this leads you to believe there is a dip in the centre of the bed

there are nine screws holding the bed down, each should have a spacer between the heatbed and the Y axis frame, have you checked that these are all in position (if the middle spacer was missing, you could get the issue you are seeing) check and correct if necessary.

if the middle is still too low, changing the front, left, right and back 'bed level adjustments' to say 20 (positive number)

will reduce the squish around the outside of the heatbed, then,

if you then adjust live Z, to restore the squish around the outside (make Live Z number, more negative)

this will also increase the squish in the middle of the heatbed.

if there is still insufficient squish in the middle, re adjust the bed level adjustments to say 30 and again adjust your Live Z value

geek adjusting until satisfied, or until you run out of adjustment

regards Joan

Joan, do you think that before doing this manual adjustment that the height of the Pinda should be changed? I haven't found that people understand what those manual adjustments are for so I'd have a hard time helping. Mesh leveling should do the sensing for you and if some other adjustment is required - why?

Maybe the math of the mesh level gets messed up if the numbers are not the correct magnitude?

Re: Print bed low in center

Good morning Themzlab,

William believes he has followed the configuration and arrived at a position that he cannot correct. he has the option of moving the Pinda, but that is unlikely to address unevenness across the bed. in it's self. one of my printers has a live Z of -0.80 and the other -1.012, they are working and I am happy to leave the pinda where it is in both instances

I choose to ensure that the pinda is always about 60mm above the bed before I start a print, because that works for me... other people have other methods that work for them.

Ideally, after mesh levelling, the Bed will not need Live Z adjustment or Bed Level Correction,

we are not in an ideal world at the moment, and we have no way ourselves of re defining the mesh bed levelling algorithm,

so what we need to do is work with what is available.

what is available, is mesh bed levelling, Live Z adjustment and Bed level correction.

William is reporting the fact that the centre of his build plate is lower than the edges... If there is no obvious mechanical cause for that (for example missing out the spacer), then to arrive at a consistent first layer thickness we need to use the above tools. (he could also consider raising the centre of his bed relative to the edges. other threads discus this option.

the Pinda is not easily adjustable in vertical height, so it is almost impossible to adjust it such that you get an absolutely correct first layer thickness, without needing Live Z adjustment, and even if we could, it is likely that changing material would result in need to adjust the PINDA again.

so at the moment I believe we are stuck with Live Z,,, additionally Mesh bed levelling and Live Z don't always provide a bed wide solution. this is where Bed level correction is available. (Other options are also offered by other makers, for example TPU Washers, Spring washers and Mould release springs. I don't have those items and I suspect William doesn't either. however there is nothing to preclude him trying those methods. )

In William's scenario, If we suggest driving the Live Z down until the centre level is Ok, we might end up scratching the PEI around the edges, which is why I suggested Raising the Extruder towards the outside of the bed before adjusting the live Z down to address the middle.

however we are restricted to William's evaluation of what is hapenning on his machine.

On My machines I seem to have the middle of the bed marginally higher than the edges and have adjusted live Z and Bed level correction to suit.

I did try mechanically adjusting one of my heatbeds but had disappointing results.

William is free to consider these suggestions and adopt or ignore them.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Print bed low in center

Hi William, first let me qualify myself as being quite new to all of this; so take this advice accordingly.

Let me also say that I have consistently found Joan's myriad input to be some of the best I have found.

I had a situation similar to yours, but my problem was that areas of the bed perimeter being lower than the center. I wasn't able to improve it much using just the "bed level correction" feature; but then I discovered that I could achieve the changes I needed by relieving the bed screws by fractions of turns around the perimeter and tightening the center screw a fraction.

So, using this method in concert with "bed level cor", I was able to adequately level the bed.

Hope this helps.

Steve

Re: Print bed low in center

Good morning,

my bed if flat, but my spring steel plate is bent, the center is higher than the edges. if I lay it on the desk and turn it with the center "hump" down, I can easily rotate the spring steel sheet (it keeps rotating). Ruler measurement also shows the spring steel is not flat.

My problem is, that when I put the spring steel on the magnetic heatbed, it is attracted to the magnets, thus the Bed Mesh Leveling points are in the same height. That "hump", however, must go somewhere - so when the steel sheet is on the heated bed, the "hump" is between the magnets = not reachable by the PINDA probe since it does only 9 points and the hump is between them.

it's only a minor issue because the overall effect is that my first layer is not perfectly squished between left side and center of the steel sheet. Is this to be considered a lower quality product like I'm considering it? I already contacted support with this, just wanting to hear your opinions

Re: Print bed low in center

Wow, that is an odd one!! About the only way I can see that happening is if something heavy fell on the center of the steel sheet. Seems to me like it needs to be replaced.

One thing I would try is placing the steel sheet in between two pieces of plate glass that completely cover the steel, and then place weights on the top piece of glass

Good luck.

Steve

Re: Print bed low in center

I'm not alone: https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/inconsistent-first-layer-calibration-t23840.html#p103017

RE: Print bed low in center

Hi William,

as I understand the situation, you currently have all of the bed level setting at 0

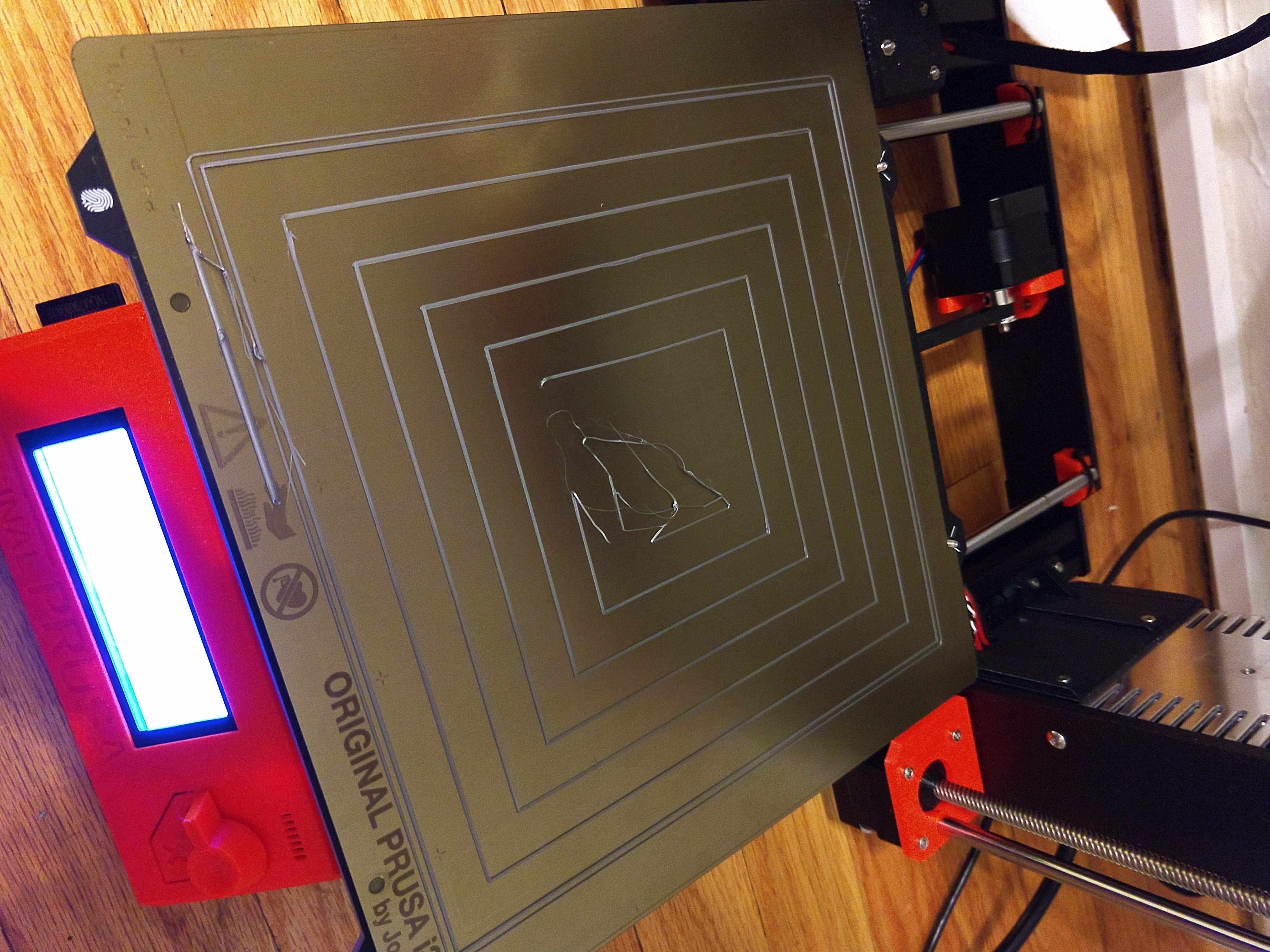

when you do your concentric square print, the squish is good all round the outside of the heatbed but there is insufficient squish in the centre

this leads you to believe there is a dip in the centre of the bed

there are nine screws holding the bed down, each should have a spacer between the heatbed and the Y axis frame, have you checked that these are all in position (if the middle spacer was missing, you could get the issue you are seeing) check and correct if necessary.

if the middle is still too low, changing the front, left, right and back 'bed level adjustments' to say 20 (positive number)

will reduce the squish around the outside of the heatbed, then,if you then adjust live Z, to restore the squish around the outside (make Live Z number, more negative)

this will also increase the squish in the middle of the heatbed.if there is still insufficient squish in the middle, re adjust the bed level adjustments to say 30 and again adjust your Live Z value

geek adjusting until satisfied, or until you run out of adjustmentregards Joan

Hi Joan,

Thanks for your amazing input across the forum.

I have the exact same "dip in the middle" issue. No mechanical issues. I've even loosen the center screw a bit with little effect.

I would like to find clarification on the Bed level adjustment workings, as I am not getting the results expected when adjusting the front, back, left and right hight

Does the bed react to adjustments like a solid plane, i.e. raising all sides by the same number also lifts the middle up by that same number, or is the center fixed at your Live Z adjustment height and the sides can go "up" or "down" independently of the middle, where the middle is not "moving" making the bed virtually convex or concave? Hope my question makes sense...

Kind regards,

Wietsche

RE:

I've been following and added a few Nylock nuts. Took me like 2h to insert and now my bet is completely level!

Hope you get to that also!

Update: What I forgot, I tried the Prusa MK3S software compencation but this was too complicated for me and it did not understand what the basic assumptions were like P.I.N.D.A probe, z-level adjustment via calibration and so on. Basically added the Nylock nuts, readjusted the outer 8 nuts heights and then did a "normal" z-level adjustment which is discussed around here!

Hi all,

My Prusa seems to have a concave bed, or else a curved x-axis rod. Unlike the edges, I can't change the software to move the center closer to the nozzle. Suggestions? The center is too low.

Sorry for the rotation.

RE: Print bed low in center

Given that this is a top google result for the low center of bed issue I am resurrecting this thread to add how I solved this issue.

I had a similar issue described in this thread where the center of the bed was seeming lower than the rest of the bed. Whether or not is actually is I don't know. I had adhesion issues near the center of the bed and when printing a full bed of parts the first layers in the center were terrible, not sticking or large gaps in the lines.

Like OP after a few nozzle changes and hot end reassembly's the live Z adjust was just about -1.45.

I tried doing the 7x7 grid of probes instead of the 3x3, I tried over extruding the first layer to try to get it to stick and it would then stick but look awful near the edges.

The issue was solved by moving the super-pinda away from the bed one half to one full turn. My live Z adjust is now -0.910 and the MK3S+ prints an even first layer at any part of the bed. It seems the Pinda probe is not accurate enough when getting near -1.5, I personally will make sure my unit stays somewhere close to -0.9 and not letting it go past-1.25.

RE: Print bed low in center

The issue was solved by moving the super-pinda away from the bed one half to one full turn. My live Z adjust is now -0.910 and the MK3S+ prints an even first layer at any part of the bed. It seems the Pinda probe is not accurate enough when getting near -1.5, I personally will make sure my unit stays somewhere close to -0.9 and not letting it go past-1.25.

Oh my god this is wonderful. I was extremely frustrated by prints popping off because the center of my bed suddenly seemed lower than the sides after a hotend change, and my live Z adjust values were around -1.7 (prior to hotend change they were around -1.4).

Following your advice, I slightly loosened the screw securing the SuperPINDA and then rotated the SuperPINDA 180° to move it slightly away from the bed. I then ran a first layer calibration to get to around -1.1, and on printing the 3x3 bed leveling calibration print, I'm getting a significantly more even print.

RE: Print bed low in center

Hello,

We are having the same issue as outlined above (center of bed is low in Z). After moving the PINDA sensor, a half turn upwards, we are seeing the same issue, although our Z offset has changed from -1.35 to -0.83, there is still strong cratering, to the point where it's dragging in the corners, yet delaminating in the center.