Re: PLA doesn't stick

Question: have any of the things you used to clean the bed been used to clean anything else? The nail brush, for example.

My experience was EVERYTHING used to clean the bed must be brand new, never used. So I now use only new paper towels for each step. To save trees and the amount of alcohol I have to use, I cut a towel down for the rinse steps. I even had problems using alcohol from a bottle I had around for a while because it had soaked up too much moisture and other contaminants from dipping q-tips into it for cleaning.

Acetone is the LAST step in the process. It dissolves the Polyethylene surface giving it a fresh tack. Sort of like a tack rag does for painting.

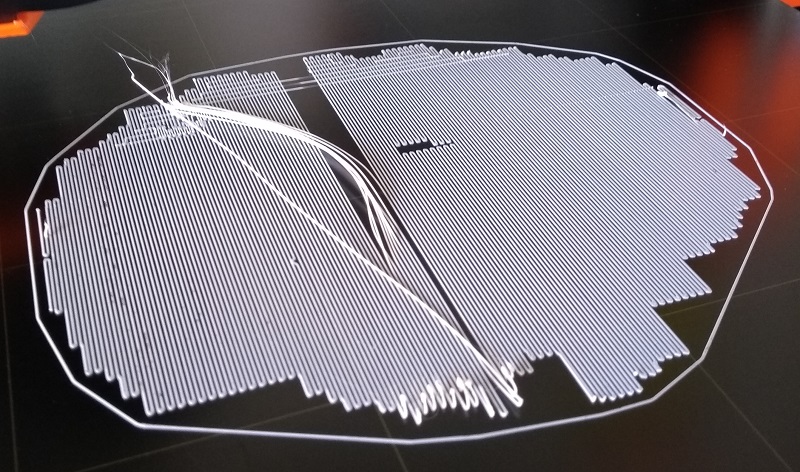

As for filament - here's an image of Prusa Beige. The first layer of the SPOOL was contaminated -- it simply would not stick to the bed. Once I had wasted the entire first layer (several meters of filament), it began working fairly well, sticking like any other PLA does. I suspect but can't prove whoever packed it had used hand lotion before handling the full spool. Taught me the lesson to not touch ANYTHING associated with PLA printing with my hands. Yes, the filament "looked" like it was almost sticking, but the second layer simply ripped the first layer right up.

ps: This was the triceratops skull I had sliced to price larger. The first layer is all support structure.

Re: PLA doesn't stick

Just for fun I swapped the orange Prusa PLA for grey Prusa PLA and reprinted the 20x20x20 calibration cubic.

It kept on the bed until the end 😯 ❓

It did not need much force to break loose from the bed, but it kept in place until the end ....??!!

btw, I have done the cleaning multiple times and also used aceton as last option. Nothing has helped, not even a bit, to keep the orange in place.

Re: PLA doesn't stick

It's funny, in threads where after several people saying finger prints are bad, to read posts like "the part came off as I rubbed my finger across it." You can lead a horse to water ...

Re: PLA doesn't stick

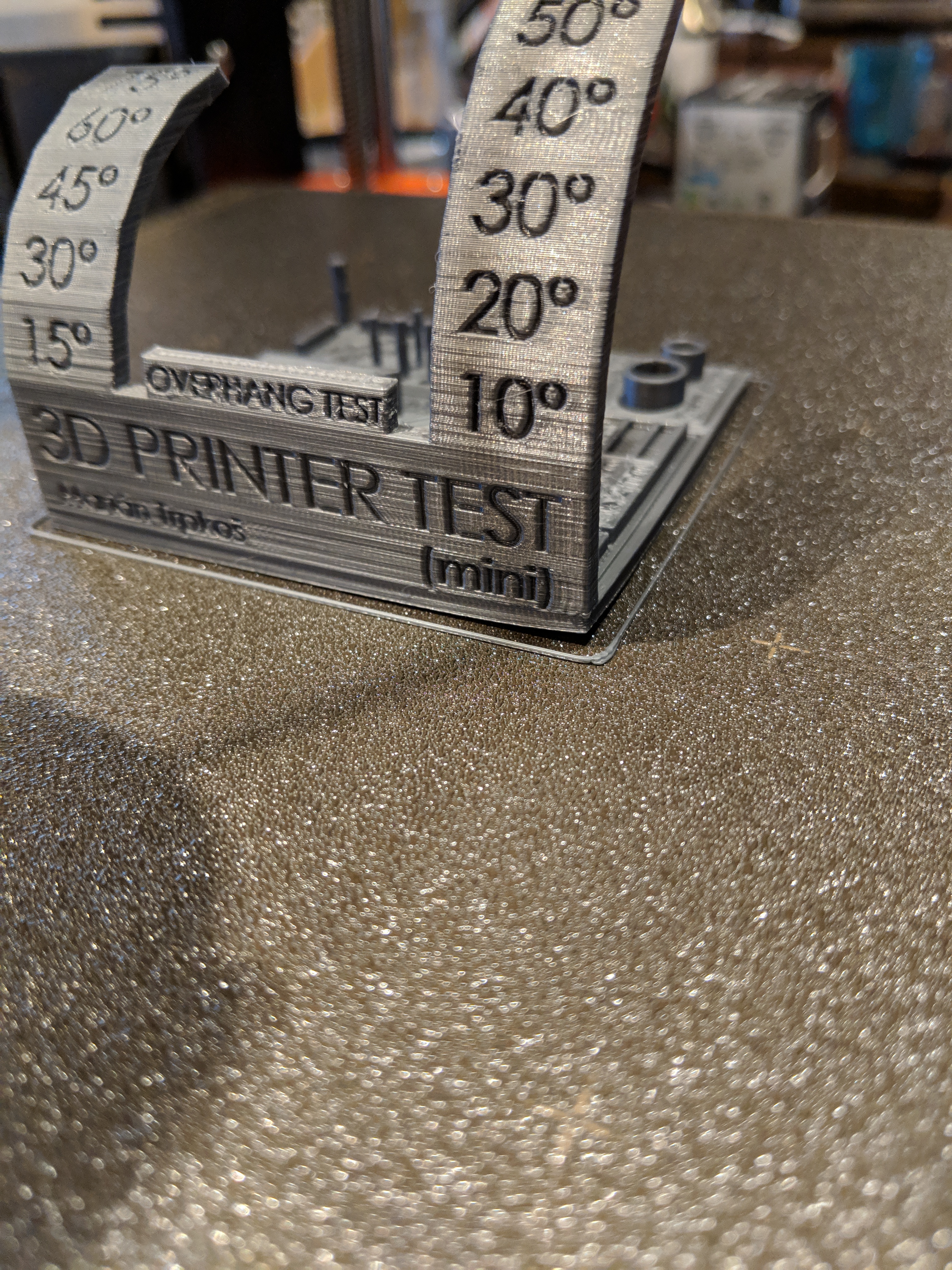

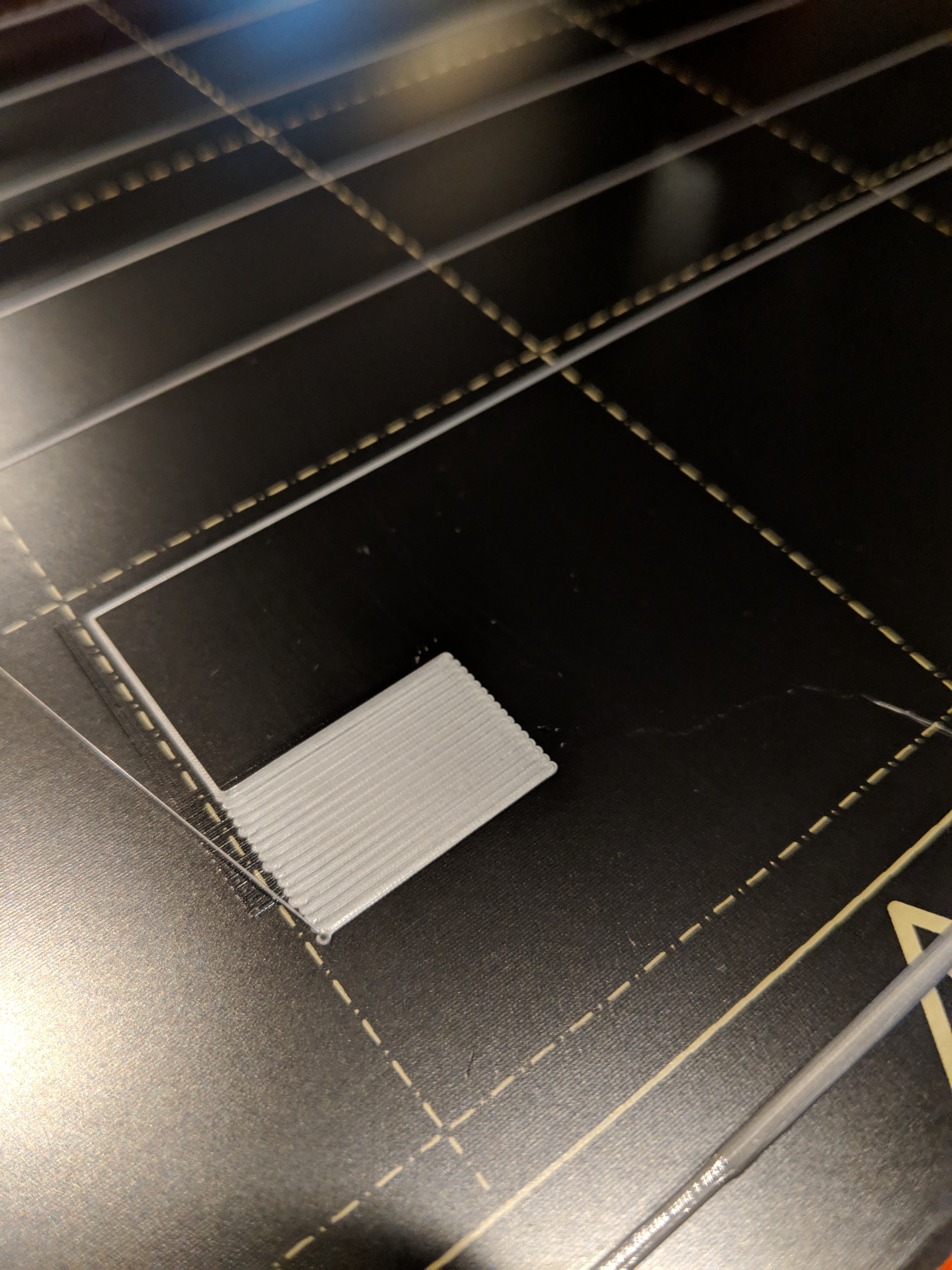

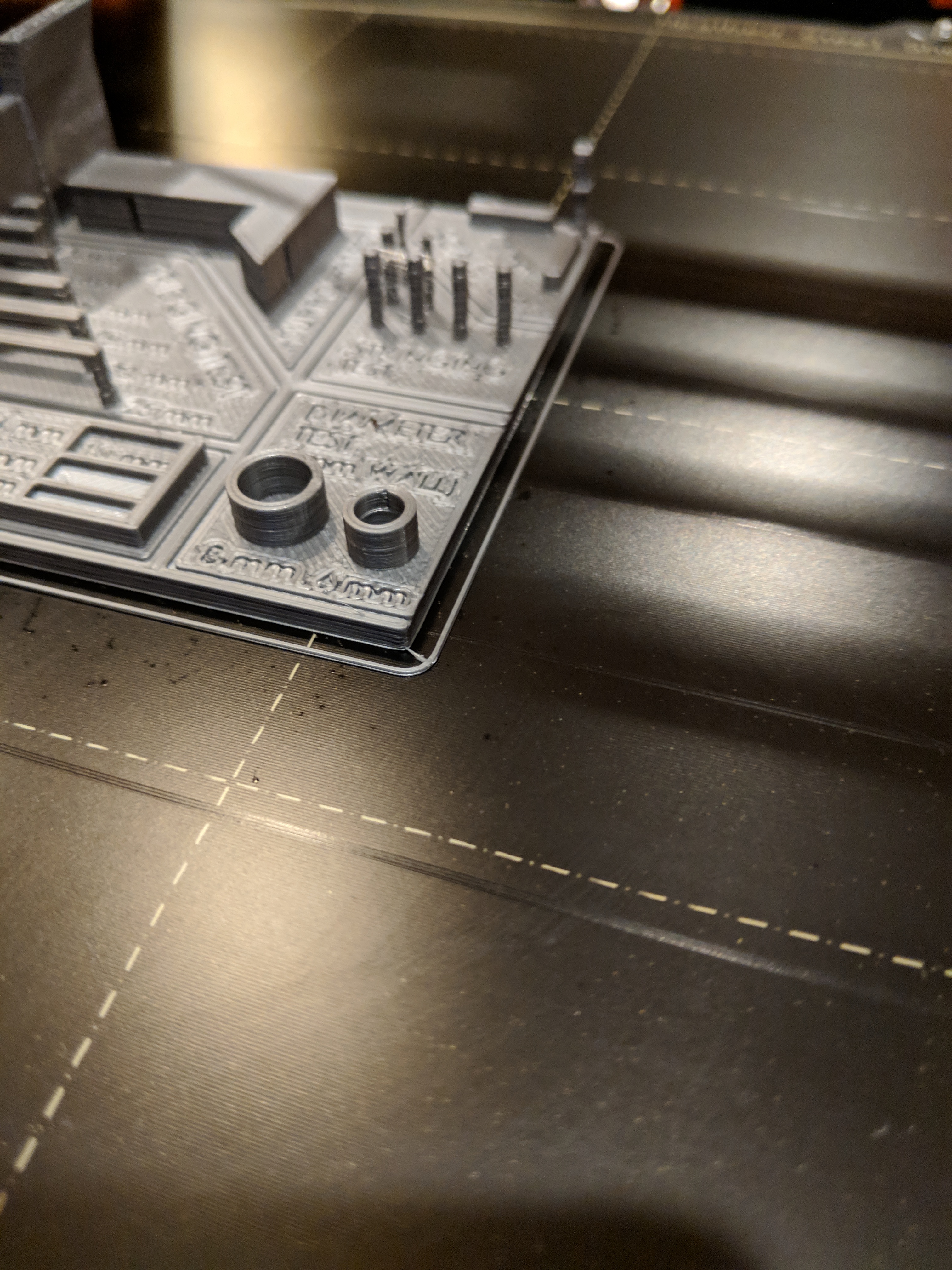

Ok, today I adjusted the z height again using the Prusa First Layer calibration. This time I moved it down more than I had in the past. It's much more smooshed to the bed. I'd say it's too far but I wanted to try it. You can see from the pic that the last line is where I ended and it's much flatter than the others. After doing this my test print stayed connected to the bed throughout the print. I'm now on my 4th print of the day (carabiners) and they are all sticking to the bed until the print is complete!!!! 😀 So now that they are sticking to the bed, I do see on every print that at least 1 or 2 corners of the print are curled up or disconnected by the end of the print. Is PLA suppose to curl at all? I thought not.

I'm getting closer! At least the I can complete a print and with just a little curling it's not affecting what I'm printing. I would like to know why PLA is curling on me. My next step is to try PETG for my Ikea Lack enclosure.

Re: PLA doesn't stick

yaaa.. nice. not sure with the fancy powder coat on the curling. im still every once in a while fighting it myself.

but at least you are going.

I have a Prusa,therefore I research.

Re: PLA doesn't stick

gvt:

Good point to switch filaments and glad you got it sorted. Yeah, sometimes a filament is finicky and switching to a new roll is good for diagnosis. Do not give up on the other roll, it will just require more adjustment. Save it for after you get everything else sorted first and then come back to it. I have 5 different colors from a manufacturer and two of them are nightmares. The other three are great, but those two gave me fits.... make sure to dry the filament too, i find it helps a lot, even PLA...

The first layer cal in the life Z adjust thread is the go to for testing the first layer. The first layer cal is too fast and too small to get a good picture of what is going on.... It does however, 'stick' the live z adjustment in your settings...

tim.m30:

I only use a half of a brand new paper towel with dish soap to clean the bed and cold water. I use a new clean microfiber cloth/paper towels to dry (all of the pics in my post show the yellow Costco microfiber cloths - $15 for 36 of them - quite the deal!) and only touch the edges when washing. I then wipe with 91% IPA with a quarter of a new paper towel. I cut and use quartered paper towel sheets to clean the bed between prints making sure not to touch it.

I do run my finger over the top only of the calibration squares to feel for raised bumps and texture while printing or after. Never the bed. it is a good test to see if the live z is too high or low while printing. I agree that hand lotions, soaps with additives, and other contaminants can effect the prints. I am almost clinical in my treatment of the process as I see you appear to be as well. I wash my hands before handling the sheet or filaments with plain non additive soap and am careful what i touch.

JB

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

Re: PLA doesn't stick

Resolved - printing successfully again!

It came down to a -proper- wash, using DAWN dish soap. The preceding wash was with a ‘septic safe’ detergent, that apparently does not do the job well enough. Using DAWN dish soap, drying with paper towels, then pouring on a puddle of IPA 91% and wiping away with paper towels... prints stayed down again.. First couple prints had slight lifting, and after each, recalibrated down a bit more (.003 or .004 down each time) and now dependable attachment and completed prints are again the norm. Also... humidity had dropped a bit to 32%...maybe that helped, maybe not. But working still today ... and another proper wash after several prints. Only removing completed prints by pushing off with a small screwdriver. Not getting fingers anywhere near printing area! Nice to be able to get on with the job.. just 15 more pieces to go, now... Hooray! Thank you to those who educated my abou the power-coat being PEI, and about just how invasive fingerprint oils can be and how particular a wash needs to be. Cheers!

Re: PLA doesn't stick

This is not good. I think you are lucky that you have such a big base that keeps the part connected to the bed.

I do see on every print that at least 1 or 2 corners of the print are curled up or disconnected by the end of the print. Is PLA suppose to curl at all? I thought not.

Re: PLA doesn't stick

Today there was a post on the Facebook Prusa group about PLA not sticking to a textured bed. Specifically the corner edges are raising up, sound familiar 😕 One of the replies said...

“That is the textured plate. PLA really doesn't like to stick to the textured plate. I eventually just gave in and started using blue painters tape if I'm printing PLA. I've had zero problems since.”

I’m going to test this theory soon. I just ordered a smooth PEI bed from Prusa. I’ll recalibrate (because of the difference in thickness) and see if this fixes ALL of my PLA adhesion issues.

Re: PLA doesn't stick

I just add a 10mm brim with the pc sheet but mostly I use smooth for PLA and PC for PGTE and ABS

Re: PLA doesn't stick

I just add a 10mm brim with the pc sheet but mostly I use smooth for PLA and PC for PGTE and ABS

My first PETG prints held very well to the pc bed.

Re: PLA doesn't stick

Would be nice if Prusa would mention that on their website 🙄

I also ordered the PEI sheet this weekend. It will be here on Thursday

Today there was a post on the Facebook Prusa group about PLA not sticking to a textured bed. Specifically the corner edges are raising up, sound familiar 😕 One of the replies said...

“That is the textured plate. PLA really doesn't like to stick to the textured plate. I eventually just gave in and started using blue painters tape if I'm printing PLA. I've had zero problems since.”

I’m going to test this theory soon. I just ordered a smooth PEI bed from Prusa. I’ll recalibrate (because of the difference in thickness) and see if this fixes ALL of my PLA adhesion issues.

Re: PLA doesn't stick

Well, I got my smooth PEI bed in from Prusa. All I can say is that it's night and day difference for me for PLA sticking. The PLA sticks beautifully on the smooth bed. Now, I am a newbie but I can tell you that going forward I'll be using the smooth bed for PLA and the textured bed for PETG and other types going forward.

Re: PLA doesn't stick

What is that dripping all over your bed? I think you just identified your adhesion problem.

Re: PLA doesn't stick

Thanks for all of the patient and detailed advice. Much of it is way over my head, since I'm not a hardware guy and I have neither the expertise nor the equipment to do much in the way of tweaking my printer.

I'm feeling pretty stuck. I've tried every suggestion that's been made and I still can't get a print to stick. Several people mention adjusting the Z. How do you do that? I do a "calibrate Z" but I don't recall it giving me an option for an offset - it just goes and does it.

Also, my printer is strange: it is not a kit, but every time I turn it on it says "your printer has not been calibrated...". The only calibration indicated for non-kits is the calibrate-Z. I do that and (a) it doesn't affect PLA non-sticking, and (b) my printer still doesn't think it has been calibrated. It is possible that this is the source of my trouble, but I haven't a clue. Might it make sense to pack up the whole thing and ship it back to Prusa to be calibrated and adjusted [and presumably, make to work 🙂 ) ? It'd be a hassle (and probably costly), but right now I don't know what to do/try next.

Re: PLA doesn't stick

Thanks for all of the patient and detailed advice. Much of it is way over my head, since I'm not a hardware guy and I have neither the expertise nor the equipment to do much in the way of tweaking my printer.

I'm feeling pretty stuck. I've tried every suggestion that's been made and I still can't get a print to stick. Several people mention adjusting the Z. How do you do that? I do a "calibrate Z" but I don't recall it giving me an option for an offset - it just goes and does it.

Also, my printer is strange: it is not a kit, but every time I turn it on it says "your printer has not been calibrated...". The only calibration indicated for non-kits is the calibrate-Z. I do that and (a) it doesn't affect PLA non-sticking, and (b) my printer still doesn't think it has been calibrated. It is possible that this is the source of my trouble, but I haven't a clue. Might it make sense to pack up the whole thing and ship it back to Prusa to be calibrated and adjusted [and presumably, make to work 🙂 ) ? It'd be a hassle (and probably costly), but right now I don't know what to do/try next.

Run a calibration via the settings. This has to be done after any significant move of the printer, so sending back would not help.

Then make sure your print bed is clean

https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f69/cleaning-the-build-plate-t26442.html

At this stage probably only isopropyl alcohol is needed.

Then run a live z adjust. This is done when a print has been started and while it is laying down filament

https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html

Only once a print starts to lay down filament you can find the live z adjust setting (not visible unless printing)

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: PLA doesn't stick

Run a calibration via the settings. This has to be done after any significant move of the printer, so sending back would not help.

Then make sure your print bed is clean

https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f69/cleaning-the-build-plate-t26442.html

At this stage probably only isopropyl alcohol is needed.

I've done that several times. My printer is a on very stable platform, but I still do the z-calibrate every now and then

Then run a live z adjust. This is done when a print has been started and while it is laying down filament

https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html

Only once a print starts to lay down filament you can find the live z adjust setting (not visible unless printing)

Aha. the things we non-kit folks never learn about. I wonder if I should ask Prusa for a copy of the kit-building manual so at least I'll have a reference for things like that. Thanks very much -- the reference to the adjust -Z page is very helpful . I have no hope of measuring the thickness, but I can compare the photos with my prints.

One thing I think I don't understand -- I always "preheat [the nozzle I guess]. But the adjust-Z page seems to indicate that you don't need to do that: you can just start printing and the printer will wait until everything is warmed up. Is that correct?

Re: PLA doesn't stick

get a good 6" Digital caliper in the $17 to $25 range such as this one

https://smile.amazon.com/VINCA-DCLA-0605-Electronic-Fractions-Conversion/dp/B017KUC6XQ/ref=sr_1_4?s=industrial&ie=UTF8&qid=1545003463&sr=1-4&keywords=digital+caliper&refinements=p_72%3A1248921011

or this one

https://smile.amazon.com/Neiko-01407A-Electronic-Digital-Stainless/dp/B000GSLKIW/ref=pd_bxgy_469_2?_encoding=UTF8&pd_rd_i=B000GSLKIW&pd_rd_r=388a5a88-0185-11e9-bba3-df00a3acce5e&pd_rd_w=PifKQ&pd_rd_wg=fYiHl&pf_rd_p=6725dbd6-9917-451d-beba-16af7874e407&pf_rd_r=PR7MRYX5G69NNP8DV2XX&psc=1&refRID=PR7MRYX5G69NNP8DV2XX

While they not the same quality of a Starratt or Mitutoyo instrument they are fine for this hobby

avoid the ones you might see under about $15 in general and especially the under $10 units.I expect that all of these are made in the same asian factories and the ones that don't inspect quite so well get the bargain branding... (I grabbed one marked Fondral at a yard sale and with fresh batteries it would measure with about a ±0.2 mm repeatability I can do better with a ruler and if you forget to turn it off it would kill the batteries over night. I use it as a scriber that I set with a much better instrument...)

You will find it quite useful in general.

btw the assembly manual is on line for all of Prusa's machines at https://manual.prusa3d.com/c/Original_Prusa_i3_MK3_kit_assembly

I use actual old fashioned micrometers but to use one well takes quite a bit of training and practice to develop the feel and working to ±0.001mm is not needed in this hobby but I am also a machinist and have lots of this sort of fancy metrology stuff in my workshop so I use it.

Re: PLA doesn't stick

What is that dripping all over your bed? I think you just identified your adhesion problem.

Not sure what that is. But my last picture that looks like there's some droplets of stuff on it, is actually working. I need to clean it again.

So, to sum up again what works for ME.... PLA on Prusa smooth PEI steel sheet. PETG on Prusa textured steel sheet.

Re: PLA doesn't stick

One thing I think I don't understand -- I always "preheat [the nozzle I guess]. But the adjust-Z page seems to indicate that you don't need to do that: you can just start printing and the printer will wait until everything is warmed up. Is that correct?

Correct. During warm you might get some extrusion. Just pull it away

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]