PETG printing disease

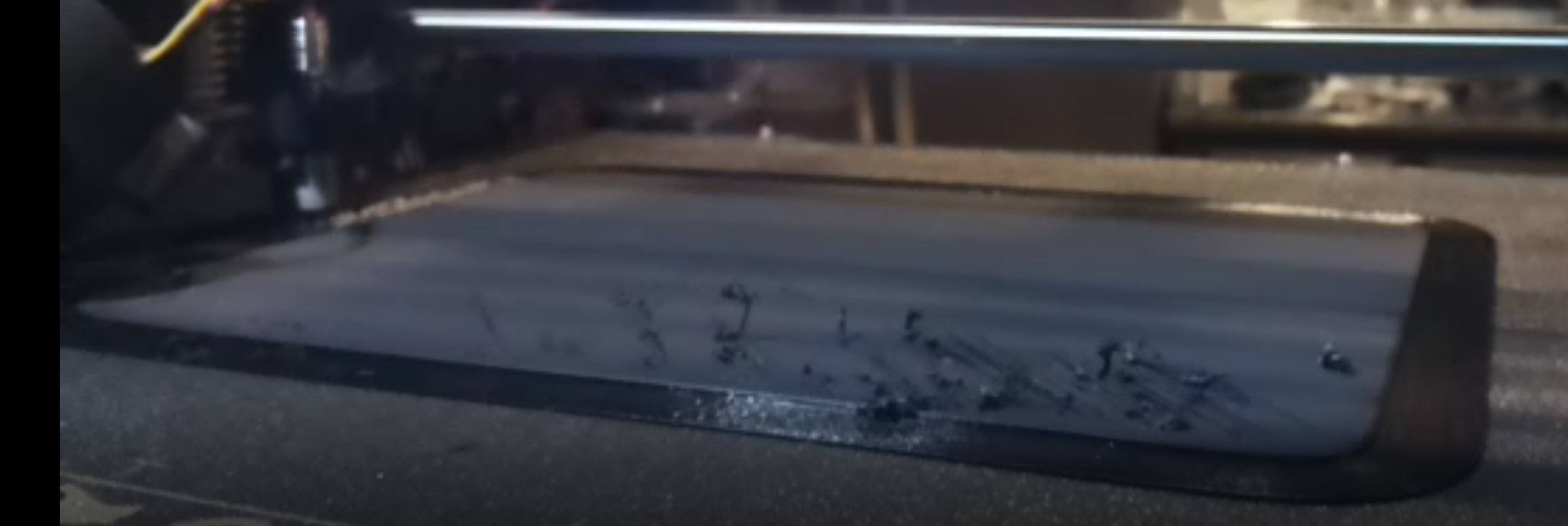

Have had excellent results with PLA but when I tried PETG got the lumpy disease as shown in pics. Tried to mess with z height and increased temps but got shite. Any suggestions welcomed.

Re: PETG printing disease

PETG likes to have room to breath, z offset looks too low. Try a large 100x100mm 1 layer test, as it prints slowly adjust z offset. What PETG brand and profile are you using? Slicer? Provide as much info as can should be able to help out more. Also make sure PINDA is at least 35C, PETG is less forgiving of this.

What this guy said. I had the same issue and it took me an afternoon to get it tuned in.

--------------------

Chuck H

3D Printer Review Blog

Re: PETG printing disease

PETG likes to have room to breath, z offset looks too low. Try a large 100x100mm 1 layer test, as it prints slowly adjust z offset. What PETG brand and profile are you using? Slicer? Provide as much info as can should be able to help out more. Also make sure PINDA is at least 35C, PETG is less forgiving of this.

Re: PETG printing disease

PETG likes to have room to breath, z offset looks too low. Try a large 100x100mm 1 layer test, as it prints slowly adjust z offset. What PETG brand and profile are you using? Slicer? Provide as much info as can should be able to help out more. Also make sure PINDA is at least 35C, PETG is less forgiving of this.

When you say make sure PINDA is at least 35C does that mean Bed temp is at least 35C? I am having similar problems with my PETG, (Amazon Basic, black, 230 1st, 235 rest of the layers, and 80 bed, with .9 retraction. No speed changes. It seems to always happen on infills mostly.

Re: PETG printing disease

Depending on your firmware version PINDA temp is located under menu-support-temperature.

PETG requires slower infil speeds, the default profile is too fast, in my experience. I recommend no more than 80mm/s.

Re: PETG printing disease

I've been printing PETG at 75% speed (by turning the rotary dial counter-clockwise as it starts the print), which improves the success of the print. Is there a way to put this into GCODE or in the Slic3r profile? Or is it just, look at all the speed values and set them to ~75% of what they are in the default profile?

Re: PETG printing disease

If you adjust in slic3r, just hit the save button and name it. Then it will always be there for you.

Re: PETG printing disease

I understand how to make custom profiles, is there a way to set the speed to 75% in Slic3r, as you can with the printer by turning the rotary dial?

Re: PETG printing disease

Ahh, you should be able to set in under speed, it accepts % instead of absolutes.

Re: PETG printing disease

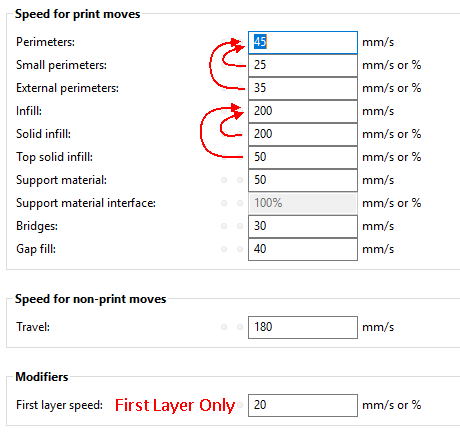

Here's what the options look like. The percentage ones are based on the previous values (as indicated below).

Here's a breakdown of how that would work.

Set Perimeters to 75% of the original (33.75).

Set Small Perimeters to 55.55%.

Set External Perimeters to 77.77%.

Set Infill to 150.

Set Solid infill to 100%.

Set Top solid infill to 25%.

Set Support material to 37.5.

Set Bridges to 22.5.

Set Gap fill to 30.

Leave travel alone I guess?

Set First layer speed to 15.

As far as I can tell, that will adjust it to 75% speed.

On the printer, I can rotate the dial counter-clockwise and it will do all of this automatically. Which is neat, but I have to do it every time. It would be nice if there was a gcode that could just set the overall speed to 75% and that would translate to the printer adjusting all of these speeds to what they need to be.

Re: PETG printing disease

ahh see what you are getting at. I don't know of a way to set overall speed at 75%.

Re: PETG printing disease

Hi,

Thanks for the insights on successfully printing with PETG. After trial and error printing 1st layer of large flat shape I found with 240C nozzle and 90C bed temps I was getting better adhesion. I also cleaned the bed with acetone instead of Iso. I started the build using -0.500 mm Z offset which worked well for 1st layer but had some material pulling up in spots to make rough surface so I adjusted to -0.475 mm Z offset and it did not happen anymore and printed smooth. For comparison I was having good results building with PLA at -0.650 mm Z offset.

Thanks,

Thomas

Re: PETG printing disease

Looks great excellent work.

Re: PETG printing disease

Just to add something not already mentioned, regarding the age of your PETG. Despite some claims to the contrary, PETG is hygroscopic. So if your filament is old, has been left out etc and you start to notice problems with the first layer (not sticking to the bed etc like it used to) then it is quite possible this will be the reason. An easy way to test is to load up a fresh role of PETG with the same settings and see if there is a difference.

Re: PETG printing disease

Just to add something not already mentioned, regarding the age of your PETG. Despite some claims to the contrary, PETG is hygroscopic. So if your filament is old, has been left out etc and you start to notice problems with the first layer (not sticking to the bed etc like it used to) then it is quite possible this will be the reason. An easy way to test is to load up a fresh role of PETG with the same settings and see if there is a difference.

Same experiences here.

Lots of issues with stringing and burned blobs until I started storing my filament in watertight boxes with big sackets of silica gel.