odd layer issue

Hi all,

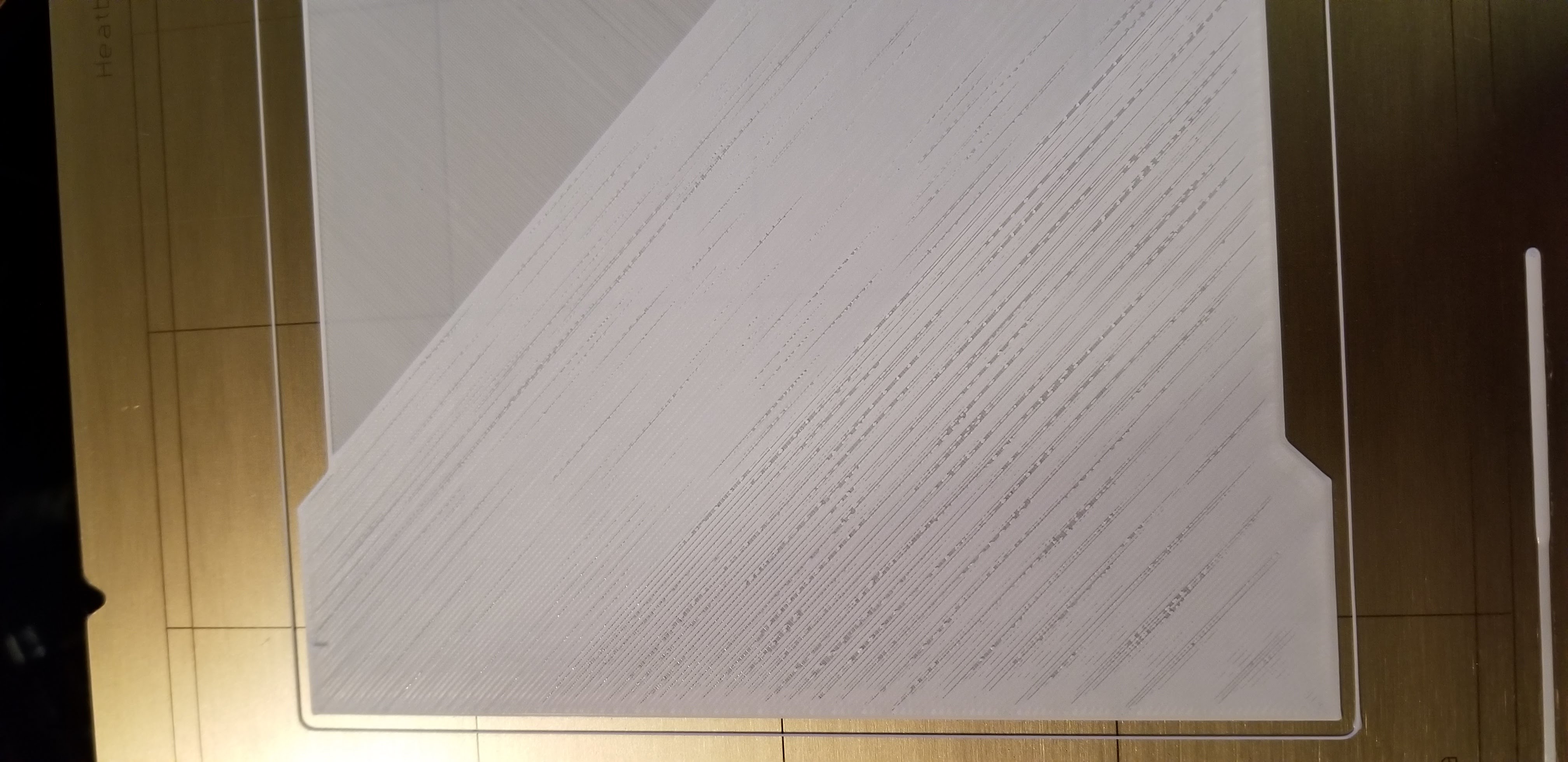

I'm hoping someone with more 3D printing experience can give me a bit of guidance. I'm having issues with top and bottom layers. It seems like some of the material (PLA in this case) is being ripped up as the nozzle moves to the next line. Any insight would be appreciated. This all seemed to start when I received a replacement assembled hot end from Prusa. I thought maybe it was a clog so I did a cold pull then with the nozzle heated up I used the needle tool included with the printer to try and clear it. Filament seems to flow OK when I extrude some through the menu. I also re-ran Z offset calibration and ended up with a value of -900. The first layer seems to go down fine, maybe a little on the squished side, but the 2nd layer just sucks.

Re: odd layer issue

Overextruding and/or too low a z-height can lead to 2nd layer print issues. Also, what layer height are you printing at (.1 mm requires a well tuned machine).

Re: odd layer issue

Overextruding and/or too low a z-height can lead to 2nd layer print issues. Also, what layer height are you printing at (.1 mm requires a well tuned machine).

I think you're right about over extruding. I thought I had it ironed out but it looks like I need to take another look at it. I was printing at 0.2mm. Thank you for the response.