newly assembled MK3S issues - z-leveling enforced, and printing curls

I just finished assembling my MK3S kit last night and tried printing the sample prusa logo on the SD card.

After a number of runs of "some problem encountered. z-leveling enforced" and it performing z-calibration multiple times, it gets around to printing.

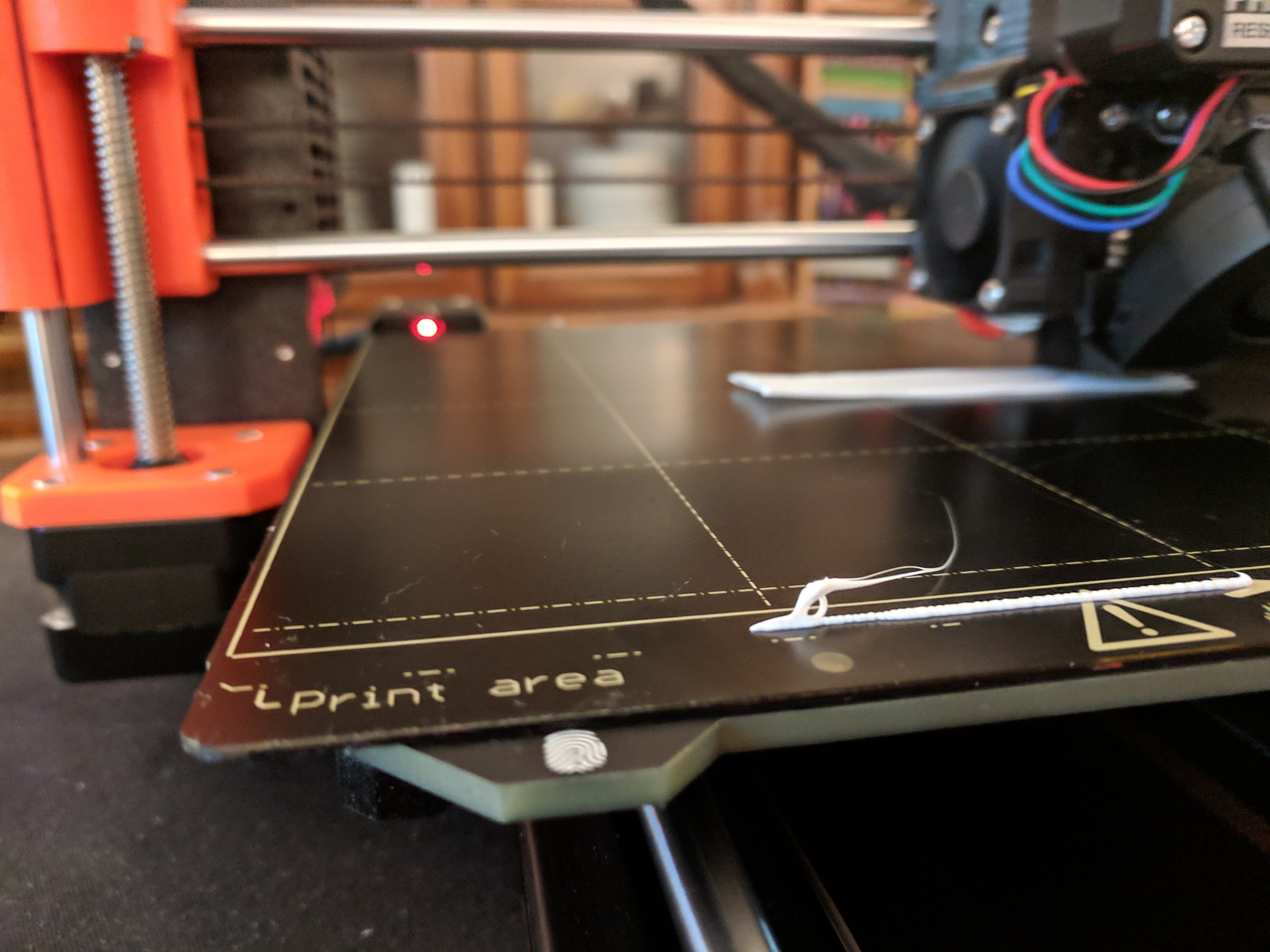

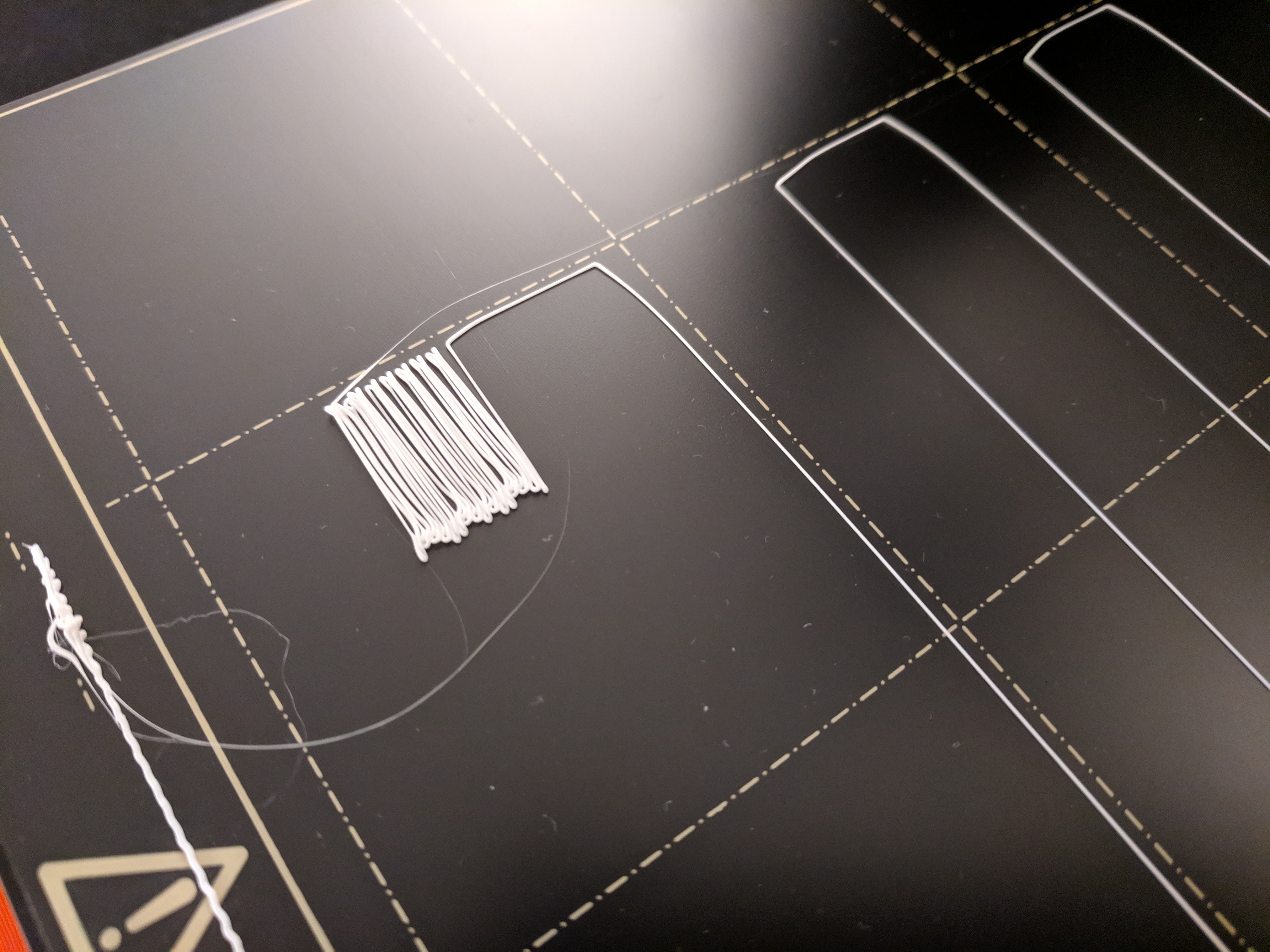

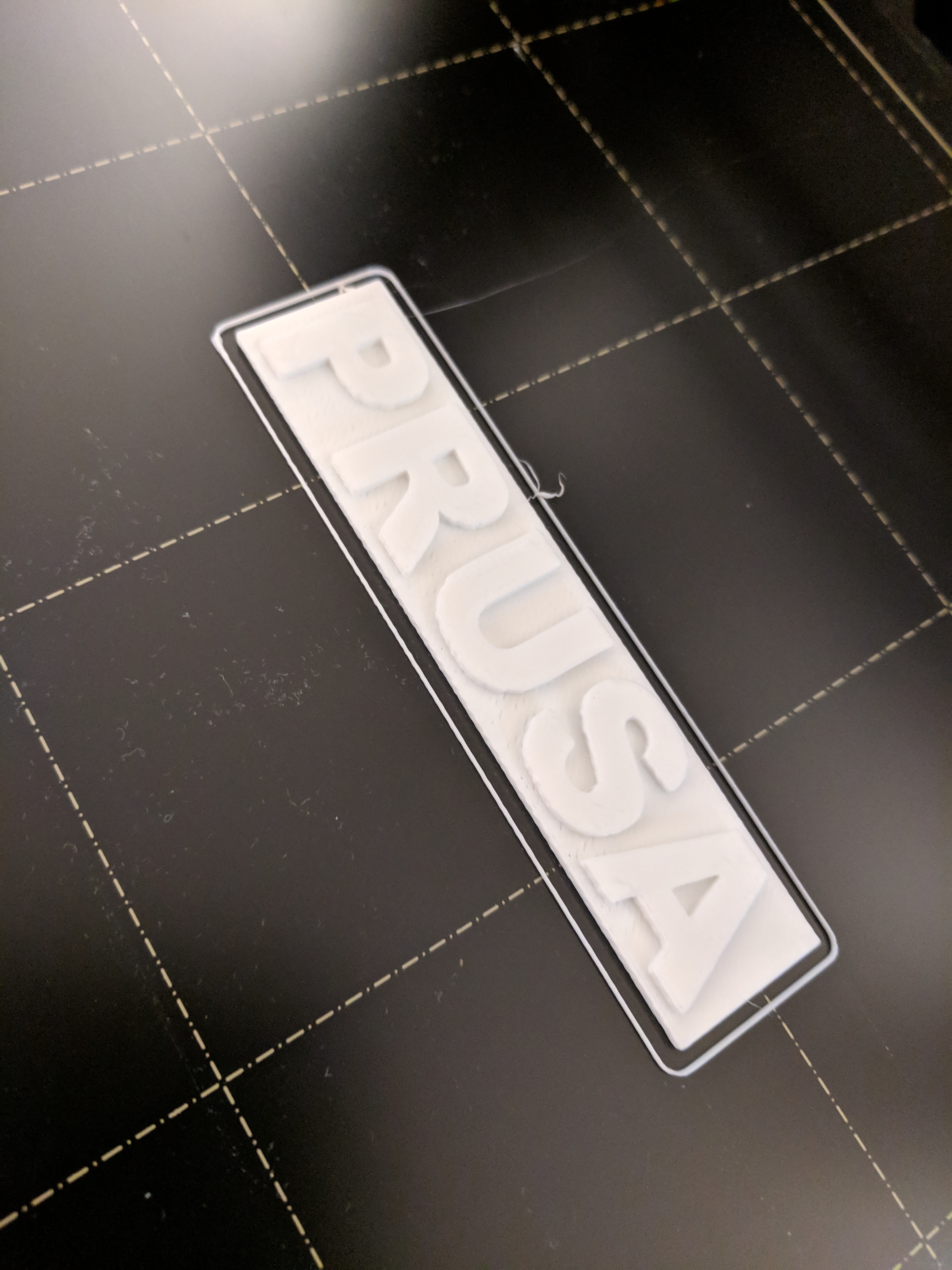

First layer seems okay. Second layer seems okay. By the third layer, one end of the material is starting to curl up off the bed. By the fourth layer, the curl is worse. By the fifth layer, the nozzle catches it and knocks the entire thing loose from the bed, and I stop the printing.

I tried this three times, getting the z-calibration issues and the curl issues each time.

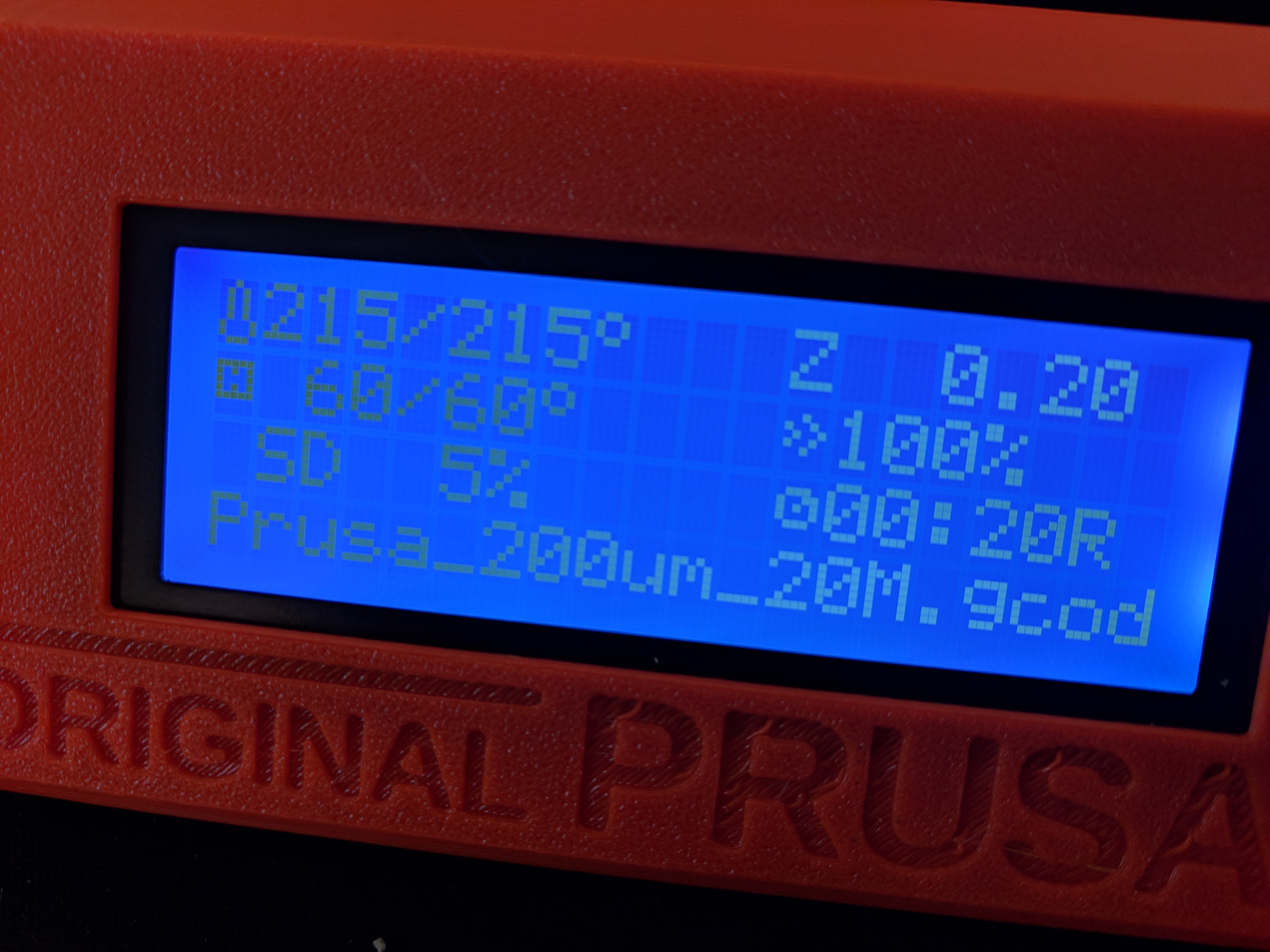

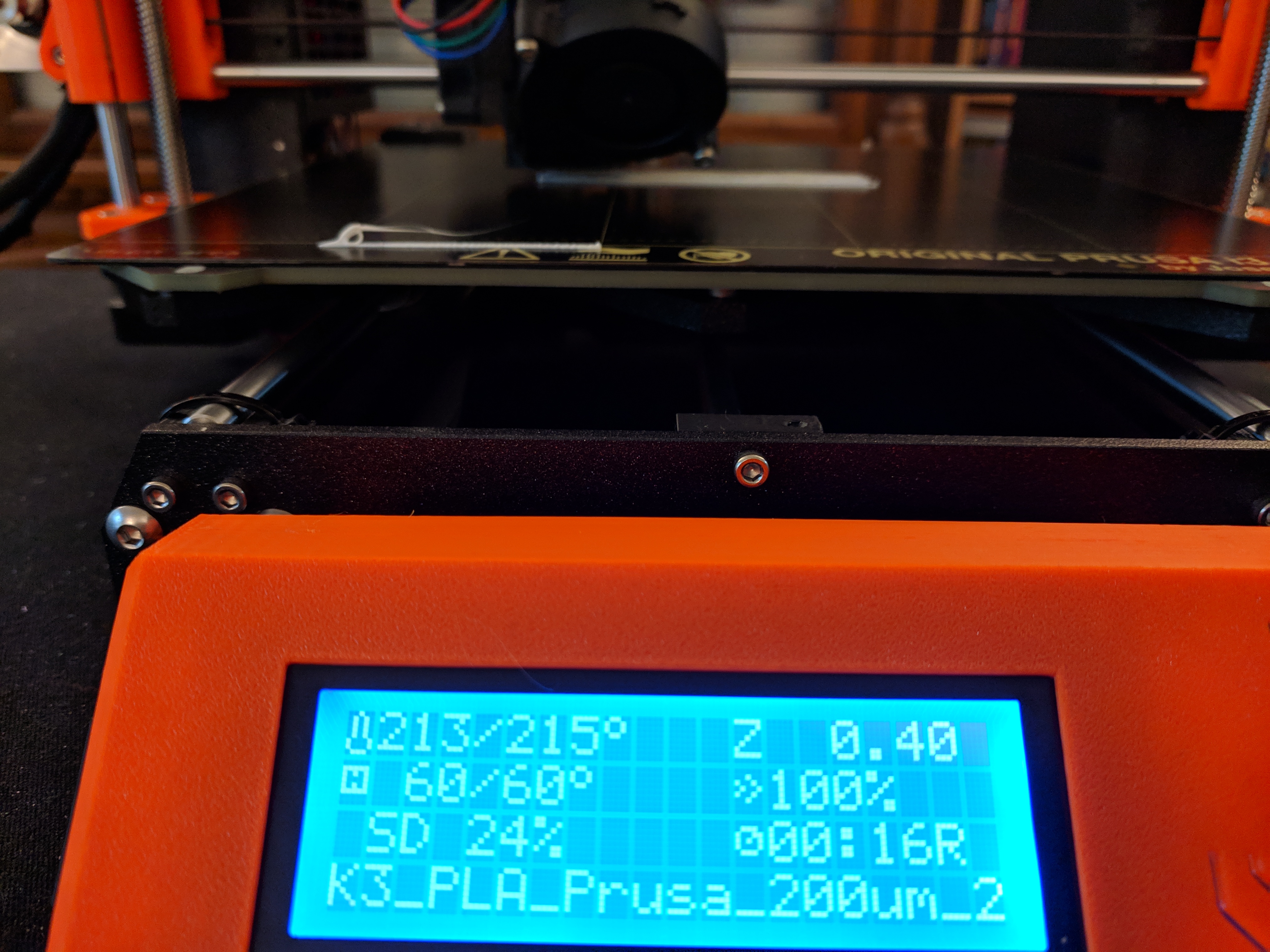

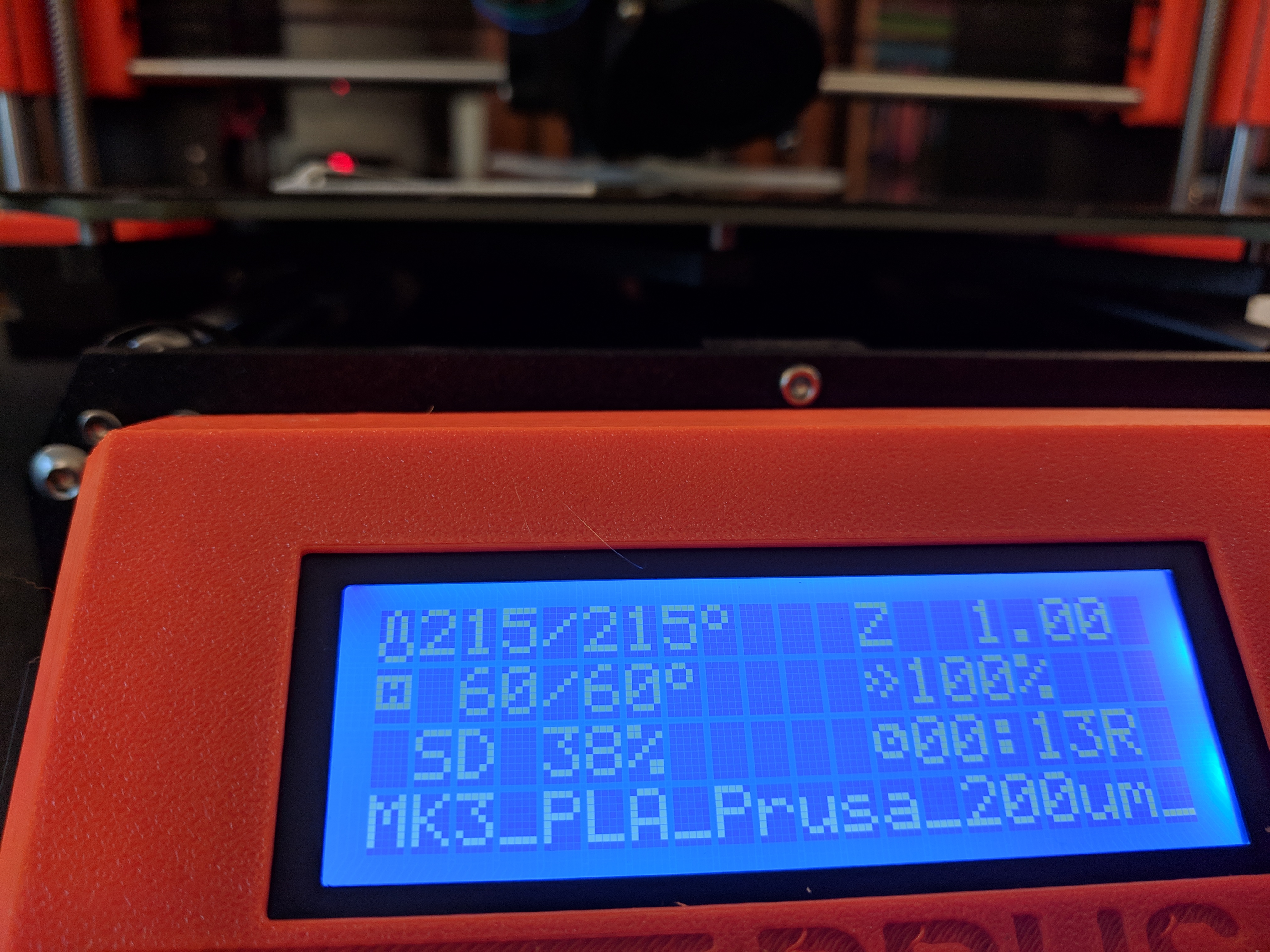

The display shows the heatbed is at 60 C.

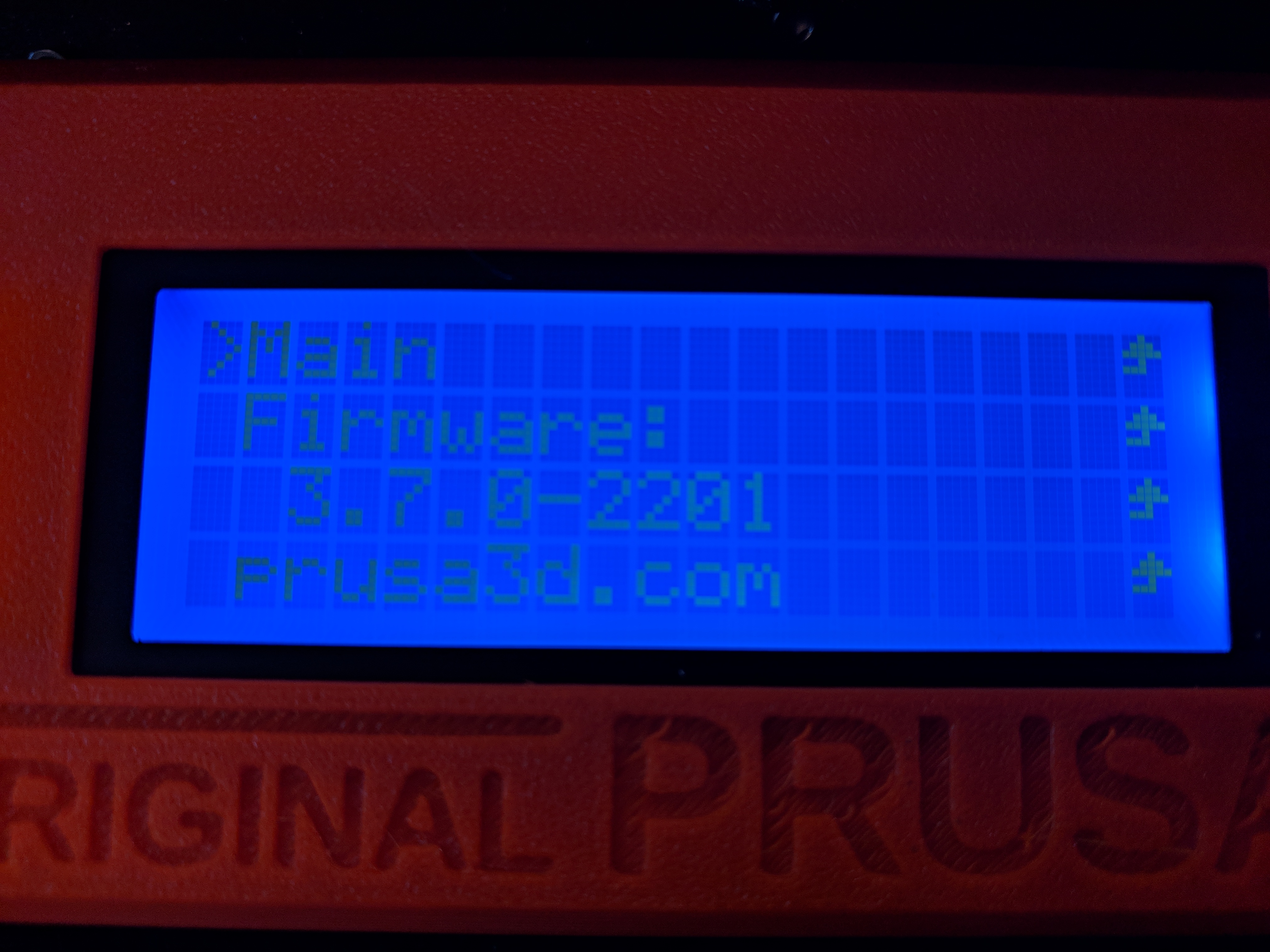

Firmware is at 3.5.3 (I didn't updated it from what was shipped, though I am considering it).

I'm seen reports from others in the forum about the z-leveling issue, and it doesn't sound conclusive whether or not firmware 3.7.0 addresses it at all.

Anyone have any thoughts on either issue I'm running into?

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

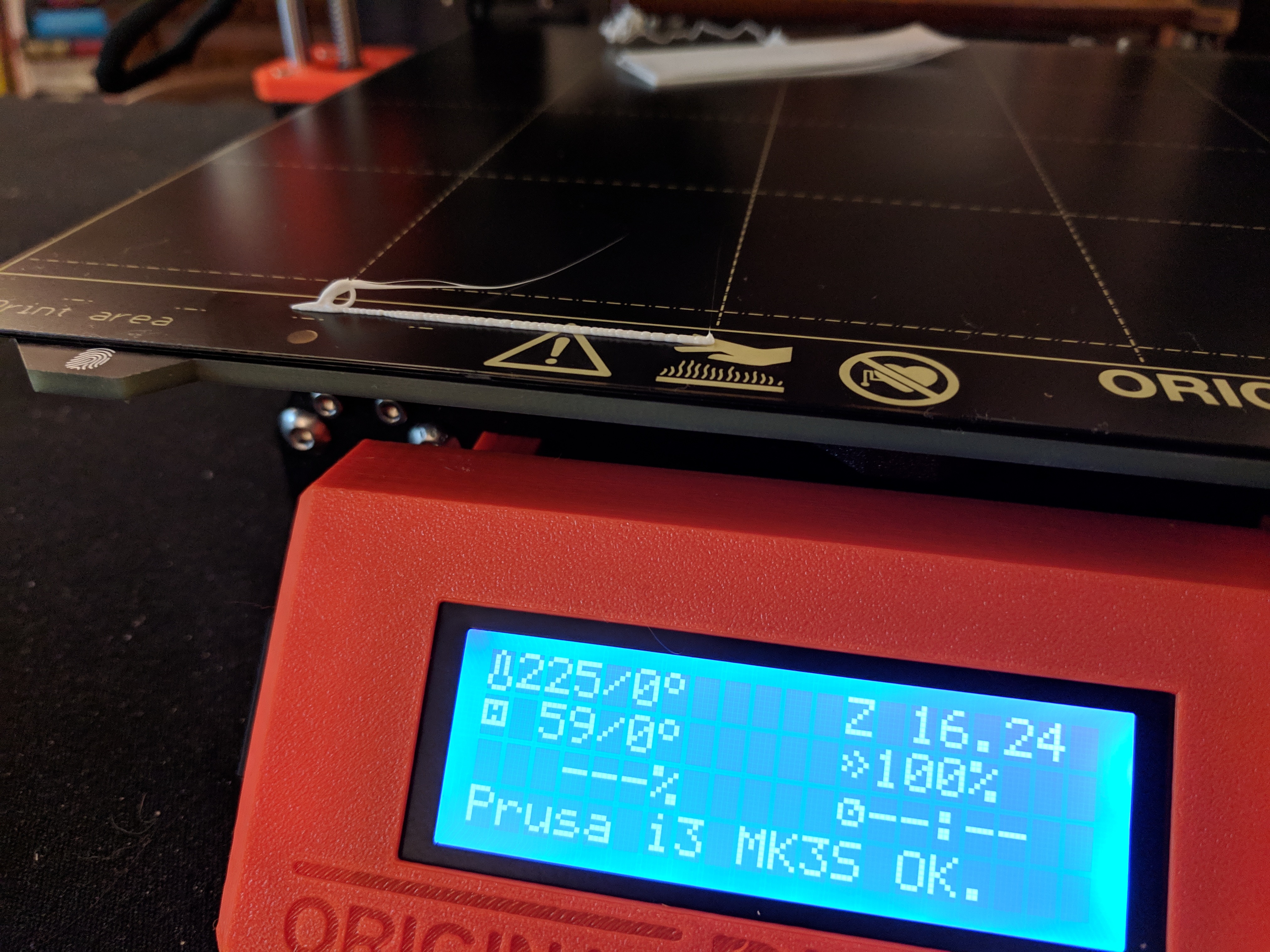

I upgraded to firmware 3.7.0-2201 downloaded today from prusa. No change in behavior. Two forced z-leveling events before it started printing. Printing failed in the same way. Same edge curling up to get caught by the extruder nozzle.

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

Sounds like a) your bed is dirty and b) there's something stuck under it.

Take it to the sink and give it a good scrubbing with hot water, clean paper towel, and a drop of dish soap (no additives - so no hand lotions, softeners, etc).

Once it is clean, handle it by the edges ONLY. Fingerprints on the bed surface will cause havoc with adhesion, and you'll have to wash it again to get them off. (IPA and acetone only spread them into a very thin film)

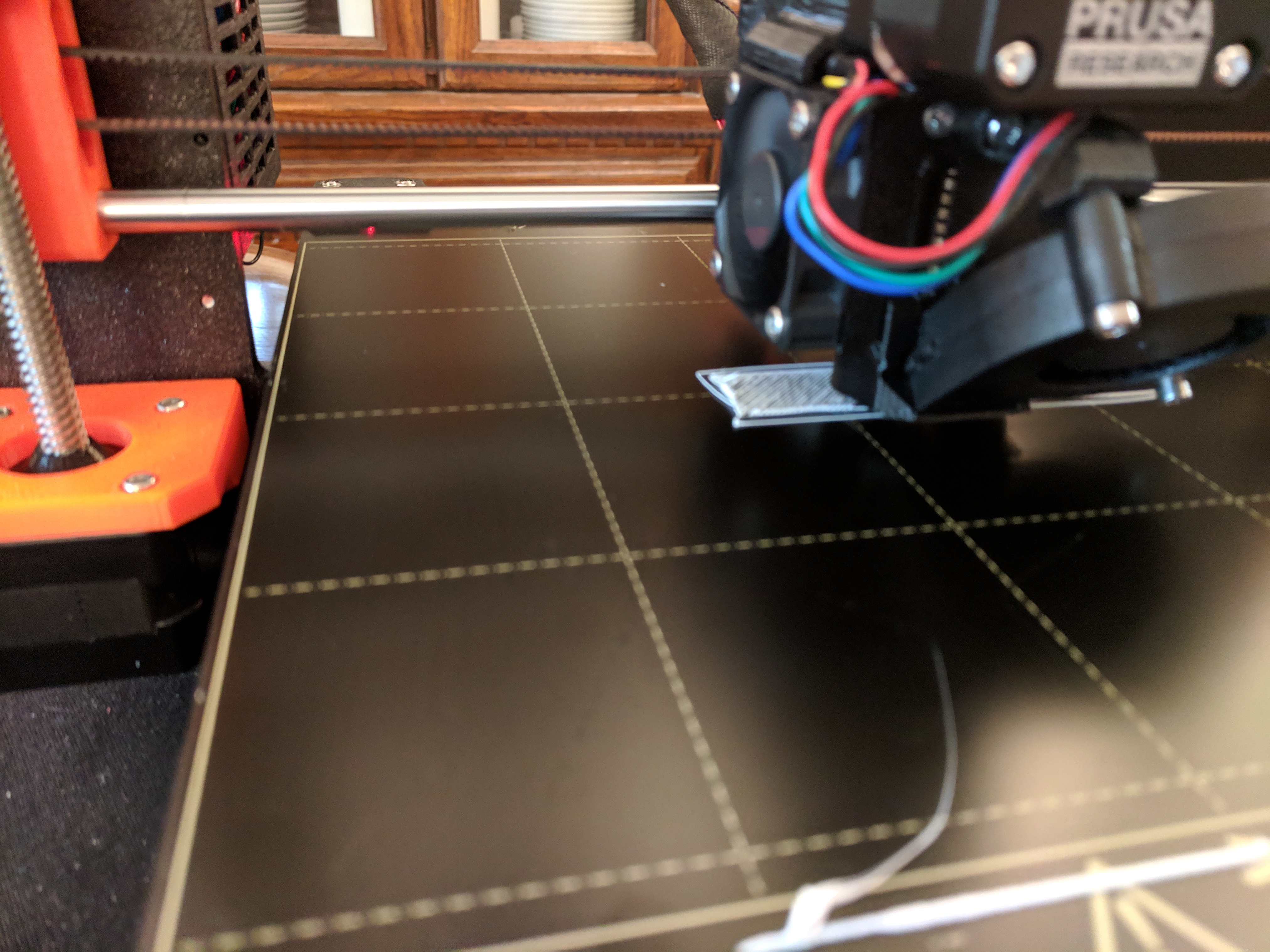

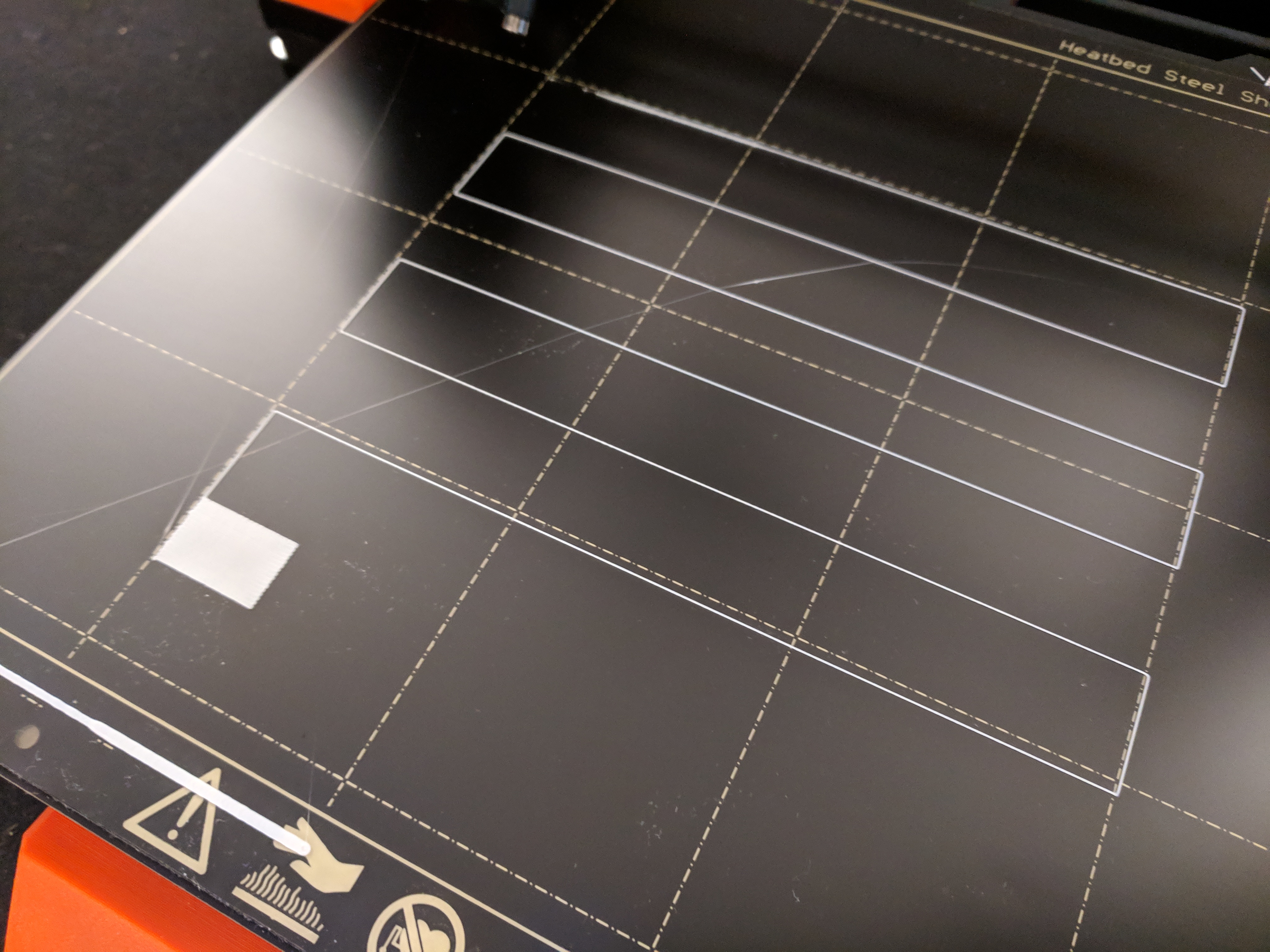

Then make sure there are no stray bits of filament, gunk, etc stuck between the heat bed and the sheet; the Z error happens when the PINDA gets a reading that is more than 2mm out of whack with what it expects. If all is clean, and the issue persists, re-run your Z calibration from the calibration menu.

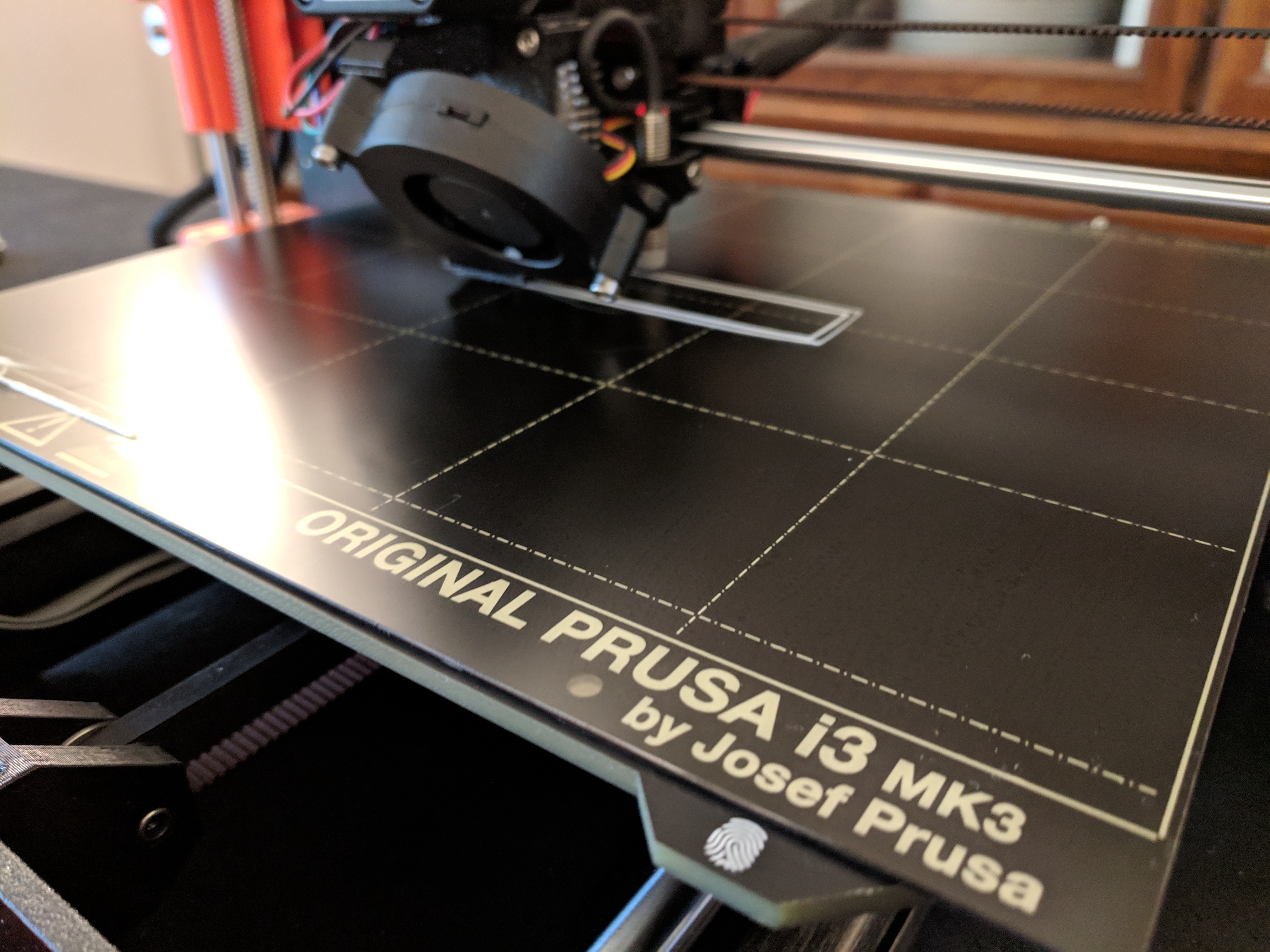

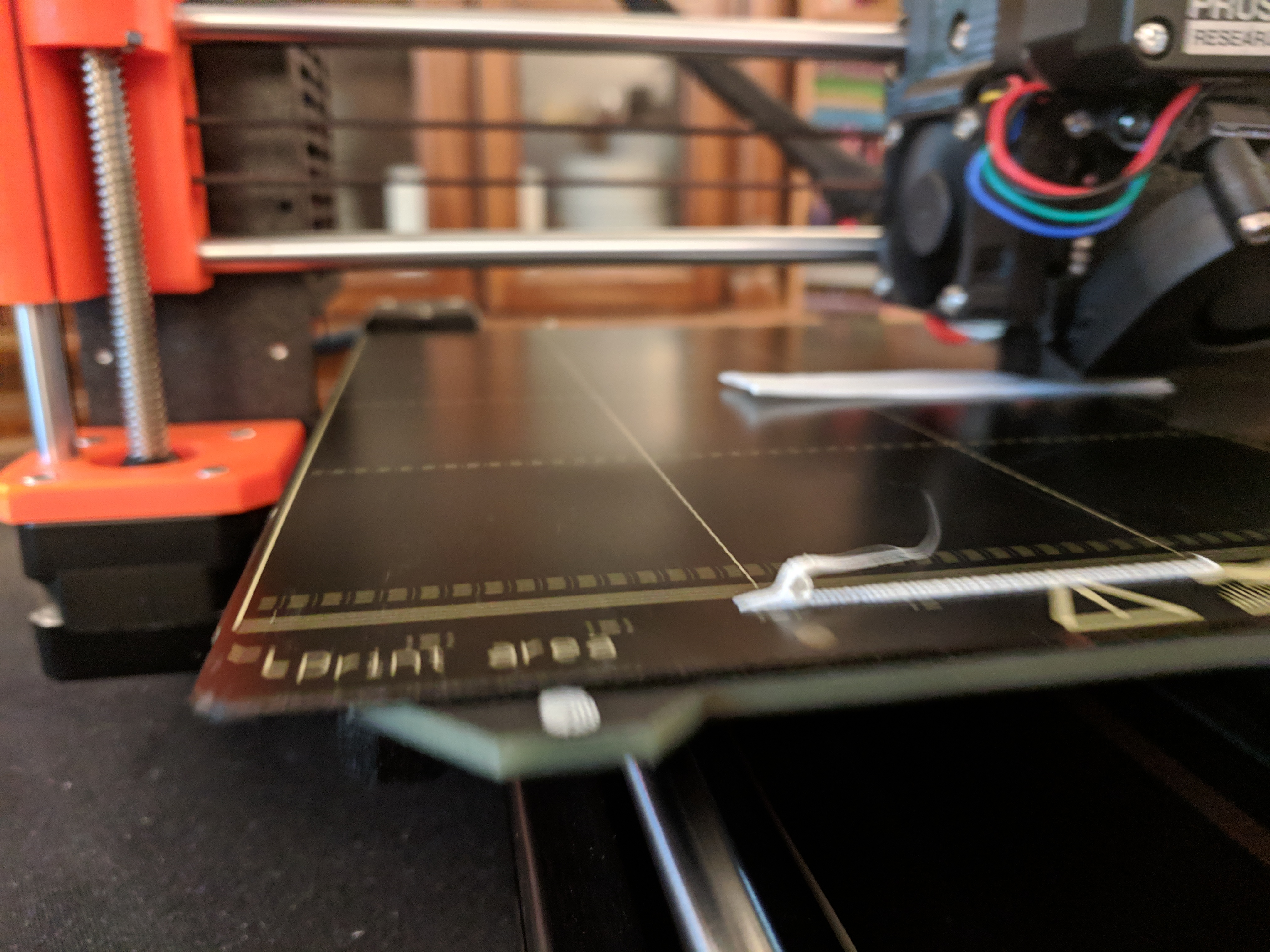

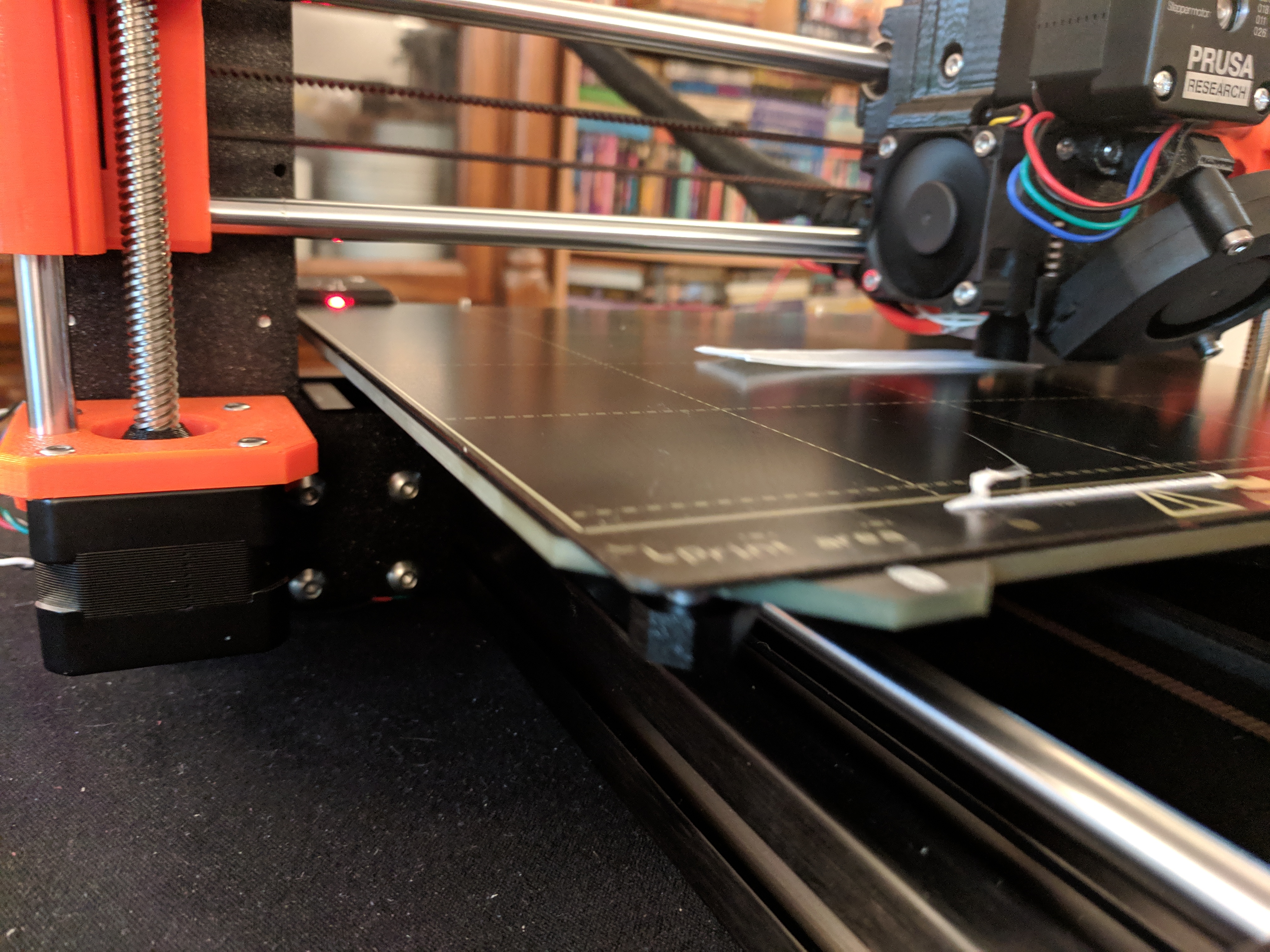

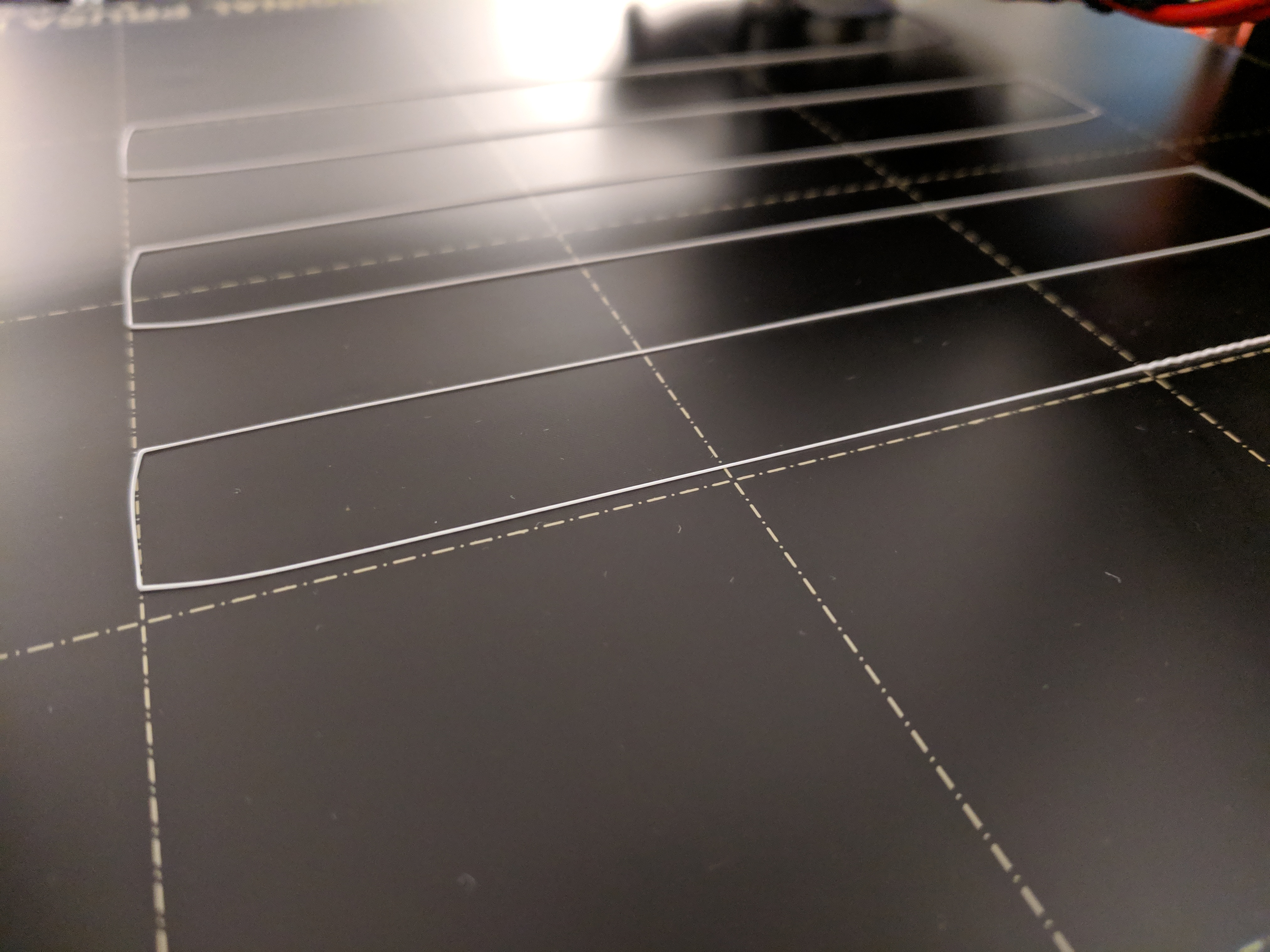

Edit: your pics came in while I was typing this. I can see your bed has streaks/spots, so it is dirty.

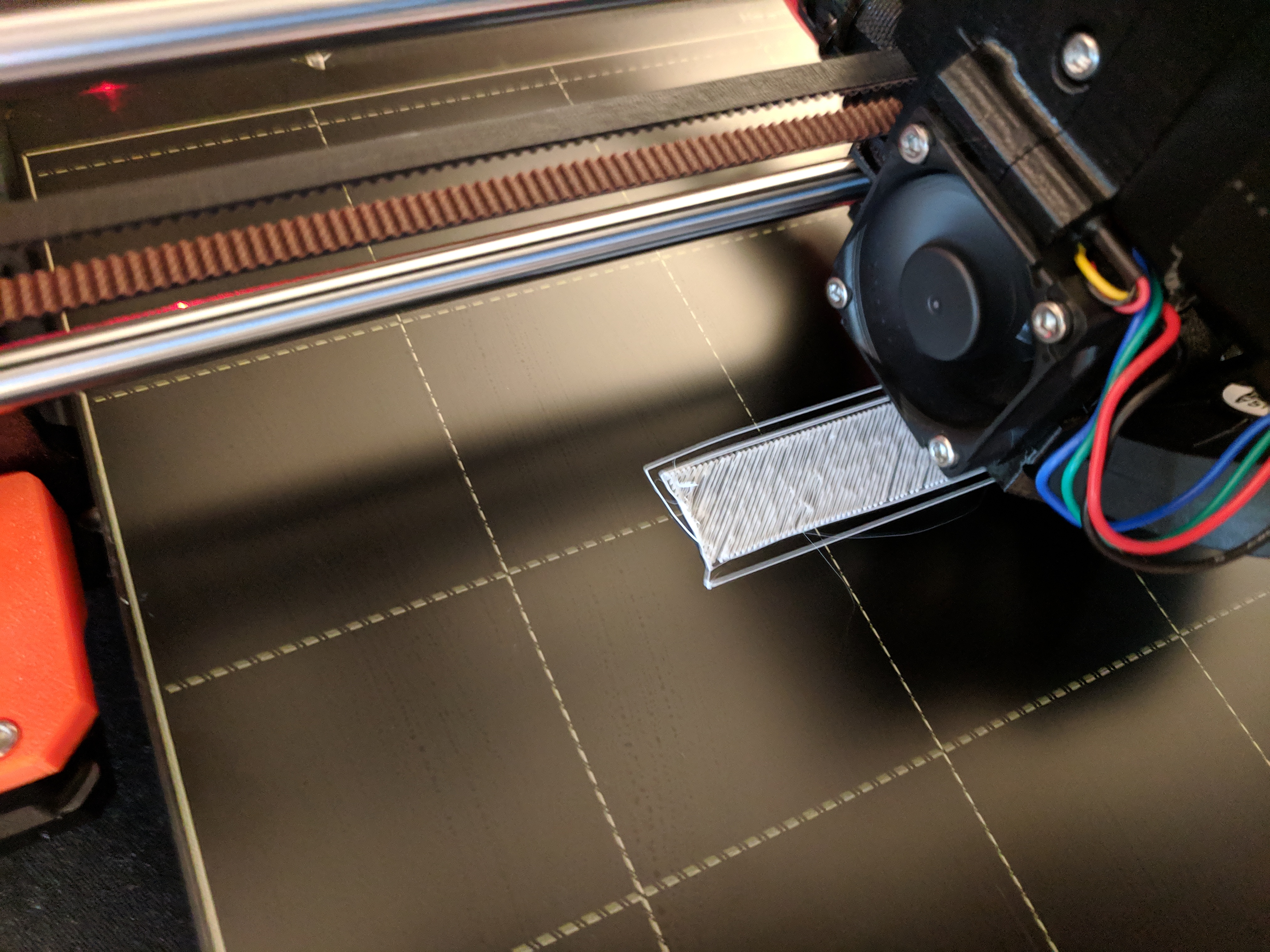

It also looks like your live Z setting may not be right, or you have massive underextrusion problems. Please post a picture of your first layer only (or the bottom layer of the failed print).

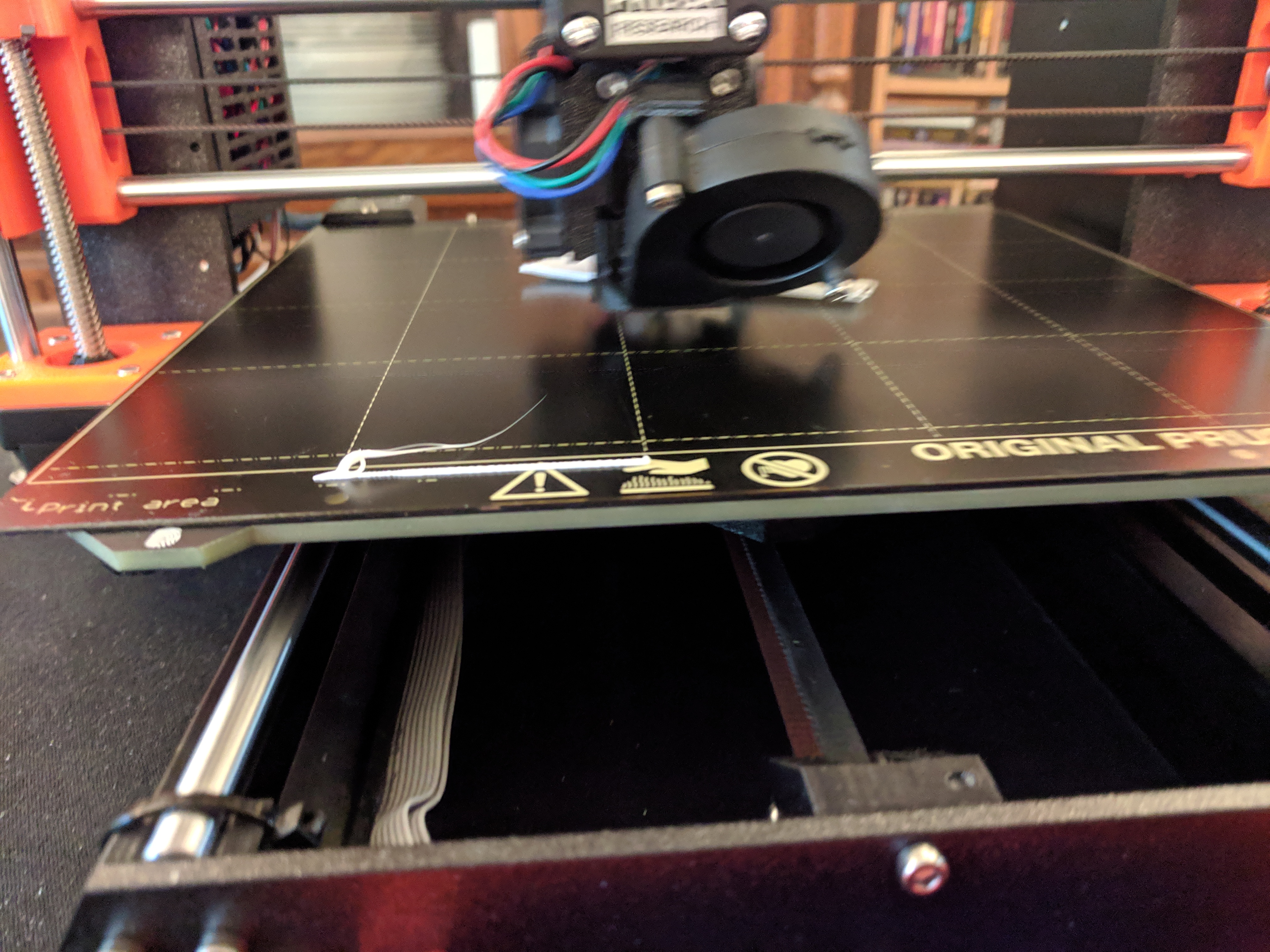

Further edit: I can see from your purge line your first layer is WAAAAY too high. See this thread for a more helpful way to get it dialled in:

https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html

Right now you're basically just laying stuff down in the air on top of the bed.

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

Thanks. I'll take a look at that.

After the first couple failures, I had scrubbed the bed with 70% isopropyl alcohol wipes which I saw suggested somewhere. I just took a flashlight to it and see streaks left behind from that. So, I'll clean it your way. 🙂

There had been some fingerprints from when I first pulled it out of its bubble wrap and almost dropped it. And again when I was laying it on the bed and wasn't ready for the magnets to yank it from my hands.

The problem with the z error is it is not consistent on where it occurs. sometimes at point 4, others at point 5. Sometimes it makes it to point 7 or 8. But so far it always occurs 2-4 times before it will start printing.

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

Tip: you can buy some disposable gloves (non-powdered, no extras like skin conditioners) which make it a lot easier to handle a clean bed without fear of adding fingerprints. (I got a few free sampler packs of nitrile ones at a science trade show that I keep beside my printer for this. Just make sure to remember which side is inside and out so you don't reverse them and keep the finger oils only on the inside. Then you can use them repeatedly until they wear out)

If you can see streaks, then as you found out, it's definitely in need of a cleaning. When it's clean the hot water should basically sheet off and not stick to the bed; it'll only leave the odd bead of water behind rather than the surface remaining wet.

I'd watch the tops of the z screws carefully when you do a settings->z-calibration; make sure the X carriage bumps against both sides and doesn't sit skewed; otherwise it won't be parallel to the build plate and you'll have exactly this problem.

With the power off and the nozzle a bit above the bed (e.g. where it rests at z=0 when you hit 'home all from the menu') gently and slowly move the extruder left and right, while watching the distance between the nozzle and bed. It should remain constant; if you see it getting narrower or wider, then something's wrong and I'd start by checking your X/Y & heatbed assembly.

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

70% IPA is 30% of something else.

Try to find some that's at least 90%.

You're closer then you think. Clean the bed, lower the nozzle (larger negative number on Live-Z) and you'll be printing like a pro.

Until your first clog 🙂

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

Ok, ran a full selftest and it failed at Y-axis. Had to tension the belt just a tad. Z-calibration looks good, the carriage reaches the tops of both screws at the same time every time (multiple times! due to...) Then I kept getting stuck on the paper test, having to power down. Finally figured out that the nozzle had a tiny drop of PLA on it and cleaned that off, so finally passed that test.

I ran a "first layer test" multiple times, lowering Z throughout and saw marked improvement. I reached -1.300 and decided that looked good, I think.

Also, the "z-leveling enforced" issue seems to have vanished somewhere in the middle of all those reboots.

Thank you ever so much for the help!

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

70% IPA is 30% of something else.

Try to find some that's at least 90%.

You're closer then you think. Clean the bed, lower the nozzle (larger negative number on Live-Z) and you'll be printing like a pro.

Until your first clog 🙂

Haha; I can wait.

I think I remember seeing 90% somewhere once. Maybe I'll check the drugstore.

Oh yeah, I liked the gloves suggestion by vintagepc. I actually have a box for teaching my son to cook (he won't touch raw meat with bare hands). I'll just repurpose them for my new printer here and let him starve...

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

Glad you got it sorted! Happy printing!

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

well done getting the firmware zig zag live z to work for you

I set my live z with this method https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html it is far better than the zig zag method in the firmware for me and I use it when changing filament type

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

well done getting the firmware zig zag live z to work for you

I set my live z with this method https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html it is far better than the zig zag method in the firmware for me and I use it when changing filament type

A few others pointed to that, too. I'm thinking about doing that to fine tune it. What I've got has at least gotten it working decently for now, but I'm not averse to improvements. 🙂

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

I didn’t have any problem before the 3.7.0 update, then immediately after had the same error. The printer obviously tried to correct itself repeatedly, raising both z-axis to the top and lowering them again, but it never recovered.

Again, my MK3S worked perfectly fine moments before the firmware update with no errors and with no changes to the print bed, which was already spotless.

ANSWER - Manuallu adjust whichever Z-Axis is too low. I noticed that the left z-axis was slightly lower than the right, despite the printer having tried and failed to align those axis itself. At least, that’s what I assumed it was a tempting as it kept elevating to the top and coming down, without ever self-recovering.

All I did was gently twist the left z-axis screw manually, lifting that one side to what appeared to be level ( I have a trained eye and simply eyeballed it ), and it has been printing fine again with no errors or warnings.

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

Sounds like you have a mechanical or assembly problem keeping it from auto-levelling. time to start looking at things that might be getting in the way or caught on the frame... zip tie heads, wires, etc...

Re: newly assembled MK3S issues - z-leveling enforced, and printing curls

I had constant forced Z correction like you mention, at least 1 every print and if it did make it through, it would crash into the left side.

For that issue, it turned out to be a faulty PINDA, which Prusa replaced.

Even after that fix, I was still having 1st layer issues.

The end solution for me was to do the Bed Level Correction settings and now I have been pretty successful in printing.

(I also had issues with fingerprints and a dirty bed that I cleaned up during the process)