New printer

Hello,

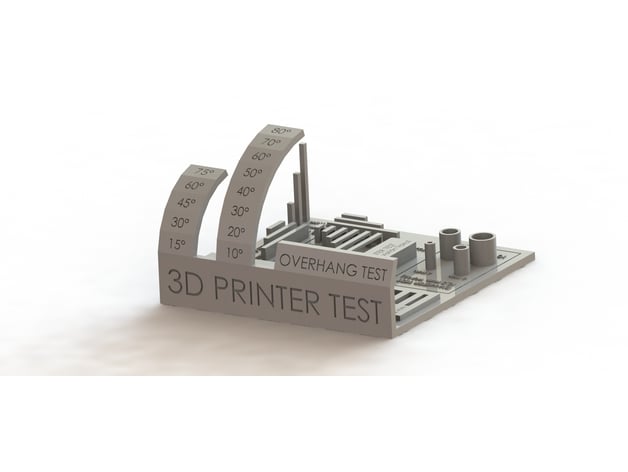

I just assembled and did the preflight on my mk3s last night. I have only printed a few things so far. I did the logo, planetary gear, and benchy from the sd card. I also have printed an AIO test from thingiverse and sliced it in slic3r PE. Below are some pictures of that.

I think I need to work on the extrusion and retractions, but I am not sure. I am brand new to this. The overhang part of the test seems ok and didnt really go bad until 50 and 60 degrees on that part. The bridging looks ok. The stringing test is a bit messy. The scale diameter test was 13.91mm OD 9.89mm ID and 7.94mm OD 3.90mm ID.

I did see that part of the tolerance test just did not print. I will have to look at the gcode to make sure it was there I think.

Any advice is welcome. Thank you in advance.

edited to fix the picture links

RE: New printer

Picture links still broken, try dragging and dropping image into text input box...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: New printer

Your picture links require a Google account and log in ... can't see them.

As for printing tests ...

Any overhang greater than 45 degrees is a win, and it all depends on slice thickness, print speed, overhang detection, and a fair bit of luck. Even part angle on the build plate affects overhangs due to air flow from the print fan. And at some point, print curl will ruin your day.

I've been printing for a while, though not really an expert at it, yet I have never adjusted the default retraction/z-lift settings other than to play around to see what they did. I believe the lore about retraction is overstated; or some brands of printers are just overly sensitive to the setting. Though, I also don't print flex or exotic materials... those probably do require some tweaks to print well. Nor do I own an MMU.

I'd check Linear Advance and Linearity Correction effects before worrying about retraction.

Stringing is filament specific, and a fix applied to one brand/color probably will not apply to another. One sure thing to affect stringing is nozzle temperature. But many have concluded a heat gun is cheap and makes the problem mostly go away. And a lot faster than trial and error.

RE: New printer

And its brother, the Kickstarter/Autodesk FDM Assessment Protocol are both testing the limits of the printer. You'll need to live with not getting a perfect score. 🙂 [Although trying to get one can be fun and a huge rabbit hole to get sucked into.]

For overhangs, you should be able to get 45° going well with any material easily, 60° with a well tuned profile, and clean 80° is only possible with black magic.

For stringing, you will always get some wispy strings between the thin spires on the tests. Improving the cooling performance of the printer should help with both the overhangs and the stringing, however that requires modification to the Prusa MK3's print cooling setup, since it isn't particularly strong.

Scale tests will mainly depend on how much your material thermally contracts, other than that, the MK3's construction doesn't lend itself to printing at incorrect scale. The number of steps of revolution on the motors is fixed, the number of teeth on the pulleys is fixed, the belt tooth spacing is fixed. There is no need for tuning that.

[And I can't see the pictures either.]

RE: New printer

Scale is reasonably well calibrated during the setup: XYZ cal has four references built into the heat bed that the printer calibrates to. Printing a 25 mm cube usually yields a 25 mm cube. Some have reported height can be off, but generally due to incorrect layer 1 trim (is your layer 1 0.200 or is it 0.165 or 0.223 ??

Just measured a print of that small test piece I did way back when: my 10 mm rail is 10.01 mm; 30 mm rails are 30.02 mm in both axis. The round objects are not any particular diameter like 10 mm, they are smaller - perhaps not metric or they're some specific thread size. The holes are within a few hundredths 7.97 for the 8 mm. Also - there are "corrected" models for ones the author admits are wrong.