MK3S+ with MMU2S overall thoughts after one month

About 3 years ago I bought my first 3D-printer: Original Prusa MK1. I like Prusa (I mean: the original Prusa brand and its innovations).

My MK1 broke down a while ago. Stood still for a few months. But I wanted to print. Repair was 1 option (which I did) but buying a new one was another (which I did also). I like the new features and smart things about the new MK3S+ and the MMU2S.

I read about a lot of problems and need for tinkering with the MMU2S but I gave it a go.

The build is nice, just like 3 years ago with my MK1. Just building the MK3S+ and do the MMU2S upgrade at the same time got me confused with 1 little part. But what one may expect: Prusa Helpdesk is great. Apparently the part was not for my MK3S+ but for the MK2, for that model the parts were included also.

First print was no problem. First 1 color. About the MK3S+ Great device. No problems found whatshowever. It does exactly what it should and it does it well. I love the filament sensors, the magnetic flexible heatbed (the powder coated version is the best!!), the hassle free end stops, the automatic bed leveling, the silence of the printer, the speed of the y-axis, the filament cutter, the spool joiner (which also works like a charm)

After a few prints I started working with the MMU2S.

A few things I encountered with the MMU2S:

1) The filament buffer just s*cks. It's a pain in the ass to put the filament through. But I own a great 3D printer, got some 3D-drawing skills so made my own. I found this one on Thingiverse: https://www.thingiverse.com/thing:3691923. Printed it but wasn't exactly what I wanted so created one to my own needs.

In my case a standing buffer. Top part hinges open with both openings for filaments in the opening lid. Now I can just lift the front of he lid and have both openings for the filament at reach.

2) The top part of the MMU2s containing the PCB and the idler is connected with two screws and springs. I didn't reconstruct it yet but this thing just NEEDS an upgrade. When I want to open the top in order to get to the pully's and openings for the filament, many times the screws and springs fell out of the holes of the lid. I got 1 spring lost at one time (used a spring from my MK1 to replace it; luckily I found the spring back a few days later). I think it would be great if there would be an extra nut at the bottom of the lid so that screw and spring cant fall out. This needs some plastic to be removed at the lower part of the lid where the lid touches the MMU2S body.

3) The rolls on which the filament is placed are also not what I like. I made new ones with bigger rolls and no parts sticking out to the side (like the yellow plastic parts) which can interfere with other things (like other filament bases). I made tubing between the rolls and the filament buffer. So far not to much friction on the filament, the MMU2S and MK3S+ just work fine with this setup.

4) The back of the MMU2S where the filament tubes enter the MMU2S should be nice connectors instead of the 'clamping' thing with the 4 screws. I plan on changing this also.

5) I've got several errors from the MMU2S where it 'needed attention'. I think the causes in my case were:

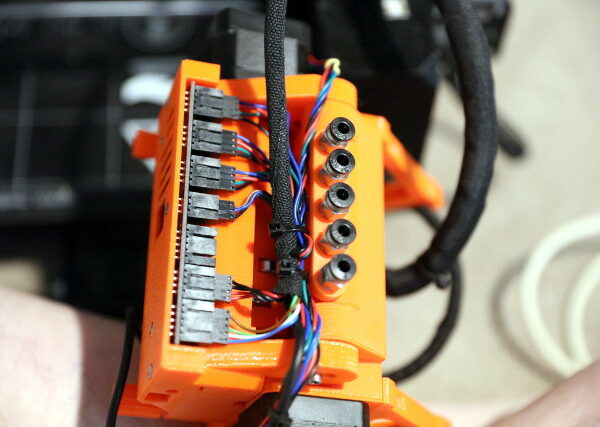

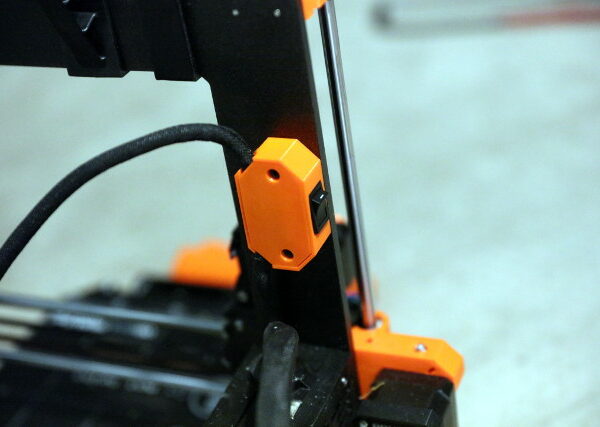

IR Filament sensor not well aligned, that MIGHT have been the cause in my case but today I think it may not have been that. I got several times all LEDS blinking red (orange!!) indicating to little power. Strangely the selector motor wouldn't turn some times, other times it would. But last few prints I got this problem at the end of a print (99% or 100% of the print done; Printing was finished in all cases but the last step was the MMU2s doing it's thing, or trying to but failed). I found the cause: The 4 color signal cable connected to the PCB of the MK3S+ next to the IR sensor cable was loose, sometimes it would do it's thing but other times it wouldn't.

Apart from these things I just love the MMU2S. I've not nearly got as many problems as I suspected after reading the internet.

Now I'll have to get more experience with other filaments then ABS and PETG which I've been using in the past. Flexfill 98 no problem so far. PC blend, prints very nice. Some warping like ABS but nice filament to print. I've done 1 succesfull print with Flexfill 45. Just 1 Marvin got of the heatbed in very nice shape. But other prints failed when the filament enters the pully in the extruder. Probably I need to loosen the tention of the pully somewhat. And PVA+ is not a succes at all so far (tried it with PC but that was a fail to expect ofcourse). I Think I'll try printing a marvin or something, in just PVA in order to see what the PVA exactly does at different speeds and temperatures.

Prusa team: thanks so far for these nice products and your great support. 3D printing is great. Keep up the great work and innovatins.

RE: MK3S+ with MMU2S overall thoughts after one month

Thanks for this post. Good the see you are happy with your purchase.

I'm thinking about getting a MMU2s for my Prusa but reading and watching all the negative posts and videos doesn't help.

I know most people only post stuff when they have problems. So this post helps to balance things a bit.

I'm looking at it like you did. Reading about all kinds of problems and fixes. But it is a hobby for me and like to tinker with it. So I will probably have a go at it too.

And when it is made by Prusa it can't be all bad. 😉

RE: MK3S+ with MMU2S overall thoughts after one month

I've had reasonably good luck with the MMU2S. I'm glad I waited a few months after building the MK3S to install the MMU2S, as the MMU2S has a much steeper learning curve and does require some trial and error to learn how to use it.

I agree that the buffer sucks. To say that it sucks is to compliment it, actually! For the past few MMU prints I just took the printer out of the enclosure, put it on the floor in the spare bedroom, and placed the spools on the holders about 5' behind the printer. It does work that way, using the open space as a pseudo-buffer, but I do keep a close eye on it even though I have not had any tangles.

I did add the mod for the quick-release tubing connectors to the MMU, as well as the power cut-off switch, and I keep that turned off most of the time and just use it as a single-color I3.

RE: MK3S+ with MMU2S overall thoughts after one month

I like the power button. However I also like the 5 filaments so I don't have to change that much. I can load the 5 mostly used filaments/colors and just select the one I need when printing.

About the filament buffer:

https://www.prusaprinters.org/prints/63379-mmu2s-filament-buffer-and-spool-holder-remix

I've got 5 spool holders side by side along the right side of my printer. Then I've got the filament buffer placed next to them. Tubings between spool holders and buffer and between buffer and MMU2s. Works great so far. No need to replace printer etc.

I see now someone also was annoyed by falling srews and springs:

https://www.prusaprinters.org/prints/4591-mmu2-tension-screw-keeper

RE: MK3S+ with MMU2S overall thoughts after one month

I printed those large orange knobs for the tension screws. You do have to use longer screws to make those work, but you just turn them a bit to adjust the tension. They are in the prints section. Finding them shall be left as an exercise for the student. 😉

RE: MK3S+ with MMU2S overall thoughts after one month

@wfvn

IR Filament sensor not well aligned, that MIGHT have been the cause in my case but today I think it may not have been that. I got several times all LEDS blinking red (orange!!) indicating to little power. Strangely the selector motor wouldn't turn some times

I seem to remember a post recently where one forum user had found there was too little power being supplied to the mmu2s, and resolved this via a different psu (external usb)

Ill see if I can find it

Tank you very much!

RE: MK3S+ with MMU2S overall thoughts after one month

Found it

Never tried but though you may be interested.

(First section of text above was meant to be a quote)

Tank you very much!