Re: MK3S stops extruding mid print (filament grinding)

try prusa 24/7 chat again and if you feel the presone helping you is not 'getting it' ask to be transferred to a senior support tech for that shift... not all support persons are of the same level of expertise

Re: MK3S stops extruding mid print (filament grinding)

I've had this happen to me before with a clogged nozzle. Buy a set of nozzles off amazon for 7 $ and replace the nozzle to see it that helps.

Re: MK3S stops extruding mid print (filament grinding)

Awesome, I've received my bearings today, and will eventually print this out. For now I need to get my problem sorted out lol.

Be aware that the Extruder assembly will hit the bottom of the TUSH at full Z height. It's good to about 200 MM. I discovered that today raising the Z to get access to the nozzle of my MK3S.

Re: MK3S stops extruding mid print (filament grinding)

Awesome, I've received my bearings today, and will eventually print this out. For now I need to get my problem sorted out lol.

Be aware that the Extruder assembly will hit the bottom of the TUSH at full Z height. It's good to about 200 MM. I discovered that today raising the Z to get access to the nozzle of my MK3S.

I’m actually planning to rebuild my entire enclosure and use the TUSH spool holders outside the enclosure. So this shouldn’t affect me 👍🏽

Re: MK3S stops extruding mid print (filament grinding)

Alright y'all so I'm pleased to say I fixed my problem. It seems the extruder gear was indeed not where it was supposed to be, as well as the PTFE tube was millimeters too long.

What I did to fix it:

Printer fixes

Disassembled my extruder assembly, and took the printed part that screws onto the extruder motor off. I got my dremel and expanded the "circle" part of the piece of plastic that sits on the circle part of the extruder motor. Just enough so that it would align the motor to the plastic bracket properly.

After that I installed a brand new nozzle for safe measure, and inserted the PTFE tube all the way down where it should sit. I trimmed about a millimeter off the top of the tube as it was slightly touching the extruder gear.

Essentially now the bondtech gear that attaches to the extruder motor was where it should be instead of being too closely centered over the PTFE tube, as well as the PTFE tube being just far enough from it while remaining close enough to allow easy filament passing.

Bottom line is this: Prusa shipped out misaligned printed parts. If anyone with a new MK3S has this same issue, I hope my weeks of banging my head against the wall will help you via this post.

Slicer adjustments

I lowered the retraction distance down by .2mm as I believed there could be some heat creep going on. So far no print has failed.

I tested a few prints for the past few days before posting just to make sure that my problems were indeed over. Attached is an 8 hour low poly bowl printed using PETG. The PETG filament worked without a hitch for a 24 hour print as well. Also attached is a PLA benchy with .15mm layer height sliced with Simplify3d with nearly identical settings as PE Slic3r. Check out those perfect layers!

Thanks to all who helped try to fix this and a special shoutout to lee.g for providing a load of insight along the way!

Re: MK3S stops extruding mid print (filament grinding)

Possible clue that I missed is all prints are failing at similar heights. Not exactly but in the ball park to each other.

I wonder if you have an intermittent fault specifically a damaged wire that goes high resistance or open circuit at a certain height.

It just goes from printing great to complete failure in a very short space of time.

Set the nozzle temperature to 220 and then using the move axis feature drive the head to the centre of the X axis and then take the head up and down slowly in the Z looking for dips in nozzle temperature. Then do the same but with the X axis driven to the extreme right. I wouldn't expect to see a shift in excess of 5 degrees.

It could be a painful exercise but if you can be there when the print fails then you can check for basic things like the temperatures reading what they should or any noises coming from the extruder. You might only have a very small time window to actually see any changes that are causing the failure.

When you do get this thing resolved this thing is going to put out awesome prints because you have checked and fine tuned virtually every part.

Thank you for your invaluable help along the way bud! See above for the conclusion of this nightmare.

Re: MK3S stops extruding mid print (filament grinding)

Thank you for your invaluable help along the way bud! See above for the conclusion of this nightmare.

Hi Abdul, did your nightmare really finished?

I mean, the problem is gone?

Didn't happen again?

I'm having the exact same issue... 🙁

Re: MK3S stops extruding mid print (filament grinding)

Hey Abdul,

Could you explain in more detail what you had to modify with the Dremel? A sketch would be preferred.

I’m in the same boat you were. Have tried lowering retraction (0.8), re-aligning the bondtech gears, replacing the nozzle, and replacing and shortening the PTFE tube. Still having failed prints at around the same layer. Can only print objects under 3hrs it seams.

Your help would be appreciated.

Thanks

Re: MK3S stops extruding mid print (filament grinding)

Hey Abdul,

Could you explain in more detail what you had to modify with the Dremel? A sketch would be preferred.

I’m in the same boat you were. Have tried lowering retraction (0.8), re-aligning the bondtech gears, replacing the nozzle, and replacing and shortening the PTFE tube. Still having failed prints at around the same layer. Can only print objects under 3hrs it seams.

Your help would be appreciated.

Thanks

Prusa support has emailed me and asked me for the same info as you. Probably in hopes to help others with this problem. I will try to work on a step by step solution of what I did today and respond to you at some point if time permits.

Re: MK3S stops extruding mid print (filament grinding)

very interesting, thank you.

I am also interested in more precision on the use of the dremel because I will start assembling the kit next Monday. I would like to know what to watch for to avoid your problem.

Great, thank you.

Re: MK3S stops extruding mid print (filament grinding)

Hey Abdul,

Could you explain in more detail what you had to modify with the Dremel? A sketch would be preferred.

I’m in the same boat you were. Have tried lowering retraction (0.8), re-aligning the bondtech gears, replacing the nozzle, and replacing and shortening the PTFE tube. Still having failed prints at around the same layer. Can only print objects under 3hrs it seams.

Your help would be appreciated.

Thanks

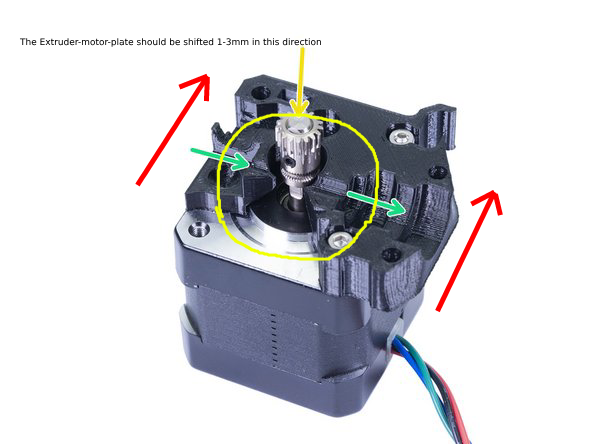

So the Extruder Motor Plate needs to be shifted between 1mm-3mm (depends how off yours is) in the direction of the red arrows. The problem is that the extruder drive gear is too off center over the PTFE tube opening that feeds the filament through the hotend.

What I did is I took a dremel to the side that touches the extruder motor (not pictured, because I couldn't find an image of it online). Essentially I've circled the circular part that you should be trying to sand down. There's a nice circular groove that fits perfectly on the motor, except it's perfectly imperfect. So if you sand the side of the circle that the red arrows are pointing to by a bit, you should be able to mount the extruder motor plate where it's aligned right.

**The goal of the dremel sanding is to get your motor drive gear away from the filament channel only slightly!!!!**

You'll know that you did it right because the top of your PTFE tube shouldn't be touching the bottom of the extruder motor drive bondtech gear. If it is, take it off and sand some more.

I'm sorry that I don't have better images of my own plate, I don't want to disassemble the hotend again but if you have trouble understanding what I've said, then I'll try to go into more detail.

It would be easier to explain if I had a 3d model of the extruder motor plate, are they available free online for the mk3s? If so I'm happy to show the proper side of the plate for a better understanding.

Re: MK3S stops extruding mid print (filament grinding)

That is great you got it fixed.

You will probably help a lot of people with this. There appears to be many extrusion issues around at the moment and it is possible that others are suffering with the same issue.

I applaud you for not giving up with it because not everyone would have done what you have to get it resolved.

Re: MK3S stops extruding mid print (filament grinding)

That is great you got it fixed.

You will probably help a lot of people with this. There appears to be many extrusion issues around at the moment and it is possible that others are suffering with the same issue.

I applaud you for not giving up with it because not everyone would have done what you have to get it resolved.

Could not have done it without a helpful push from the community as well, thanks Lee!

Re: MK3S stops extruding mid print (filament grinding)

Prusa support forwarded me a link of the MK3s 3d model that I could break down. Here is the part that needs to be sanded down, from the correct angle.

The green shading is about how much I sanded (think 2-3mm max) and the yellow circle around the extruder gear is giving the direction that the gear should be going in.

Again the point of this is to align the gear correctly over the PTFE tube, as some of the mk3s are coming with a misaligned extruder motor cover part.

Re: MK3S stops extruding mid print (filament grinding)

Did you need to re drill the holes for the motor screws or were they actully in the right place and had previously been put under strain assembling the motor plate?

Re: MK3S stops extruding mid print (filament grinding)

Is this misalignment is (semi)intentional; or is it an actual mistake? Because I'd rather not fiddle with filing the part but wait for the fixed CAD/STL file to print; And I'm still hesitating with cutting up the PTFE

Re: MK3S stops extruding mid print (filament grinding)

Hello Everyone,

I believe I have some good news for you.

Firstly, Abdul, thank you for the timely response and the diagram.

I was hesitant to modify the part for the same reasons others have stated (screw hole alignment to motor). I did however, after a bit of debating, slightly sand the inside circle to allow me to just slightly skew the motor while still being able to screw the plate back on. Unfortunately, my extruder clogging continued to happen after this.

I resorted to the Prusa LIVEchat for help, and after 2 days with two different representatives, I was told to send photos of the outside of my extruder to them for more extensive review. It seemed like they were brushing me off, as I couldn't see how this would help diagnose the problem.

Finally I stumbled upon a video on YouTube which seemed to explain the issues we've all been having, and the solution made a lot of sense to me.

I've made some diagrams to help explain the problem.

The first image shows a comparison between E3d v6 heatbreaks, and highlights where the Prusa's heatbreak has an internal bore diameter change from 2.0mm to 2.2mm. This is where the heatbreak screws into the heatsink on your hotend. Apparently, this design change is to better support the changing of filaments when using the Multi-Material upgrade.

The second diagram shows how The Prusa's heatbreak causes clogging to occur when heat-creep happens from the nozzle end. As the heat builds from longer print times, it manages to travel up the heatbreak to where the bore change happens. This causes the filament to soften and expand to fill the 2.2mm bore. Once this happens, the bondtech gears can no longer push the filament down, since it is trying to fit a 2.2mm object through a 2mm hole. This in-turn, causes the gears to erode the filament causing the notch many people are seeing in their jammed filament.

The third image shows a piece of nylon cleaning filament I used to do a cold-pull from my extruder after a clog. As you can see in the image, the filament residue that was pulled from the hotend is not close to the nozzle, but is in fact aligned with where the bore change happens in the heatbreak. This confirmed for myself, that the heatbreak theory was likely the culprit of my continuous clogging.

I solved the problem by buying a standard E3d v6 1.75mm heatbreak and replacing the Prusa heatbreak (Make sure you use Thermal Paste on the heat sink side). So far, I've done two successful 12 hour long prints with no issues. I used the same Filamentum "Crystal Clear" PLA and ran it at standard Temps with 0.8mm retraction, the same settings that were causing my previous clogs. I was able to print all of the same G-code that had previously failed at about the 3-4 hour mark with complete success. I'm now starting a 48 hour print and expect it to work without any issues.

I hope this helps others, as I was in a bad spot for the past 2 weeks. I bought my Prusa kit for business purposes, and the clogging was causing me to have issues with a client I was making prototypes for. I hadn't even considered I would have problems with a brand new machine and miss key deadlines due to it being inoperable when I took the job. Here are some of the failed prints after the 3-4 hour mark, I would show you images of the completed prints but due to the intellectual property of the designs I can not.

I know this is a long post, just wanted to be thorough with the explanation so others can resolve their problem in a timely manner. If you don't plan to use the Multi-Material feature of the Prusa, then this solution should work for you. It might even work with the upgrade, I don't have he MMU 2.0 so i can't say for sure.

Here is the link to the Youtube video if anyone is interested, I wouldn't recommend their oiling solution, but to each their own.

Also I have a i3 MK3s Prusa kit, the heatbreak should solve the problem for everyone with the MK3s and the MK3 who are experiencing this type of clogging

Re: MK3S stops extruding mid print (filament grinding)

Here are some failed prints at about the 3-4 hour mark.

Re: MK3S stops extruding mid print (filament grinding)

Did you need to re drill the holes for the motor screws or were they actully in the right place and had previously been put under strain assembling the motor plate?

There was enough play to push them all the way to the side I needed to push them to in order to screw them in. I did NOT sand down the motor screw holes. Again we're talking millimeters here.

Re: MK3S stops extruding mid print (filament grinding)

Hello Everyone,

I believe I have some good news for you.

Firstly, Abdul, thank you for the timely response and the diagram.

I was hesitant to modify the part for the same reasons others have stated (screw hole alignment to motor). I did however, after a bit of debating, slightly sand the inside circle to allow me to just slightly skew the motor while still being able to screw the plate back on. Unfortunately, my extruder clogging continued to happen after this.

I resorted to the Prusa LIVEchat for help, and after 2 days with two different representatives, I was told to send photos of the outside of my extruder to them for more extensive review. It seemed like they were brushing me off, as I couldn't see how this would help diagnose the problem.

Finally I stumbled upon a video on YouTube which seemed to explain the issues we've all been having, and the solution made a lot of sense to me.

I've made some diagrams to help explain the problem.

The first image shows a comparison between E3d v6 heatbreaks, and highlights where the Prusa's heatbreak has an internal bore diameter change from 2.0mm to 2.2mm. This is where the heatbreak screws into the heatsink on your hotend. Apparently, this design change is to better support the changing of filaments when using the Multi-Material upgrade.

The second diagram shows how The Prusa's heatbreak causes clogging to occur when heat-creep happens from the nozzle end. As the heat builds from longer print times, it manages to travel up the heatbreak to where the bore change happens. This causes the filament to soften and expand to fill the 2.2mm bore. Once this happens, the bondtech gears can no longer push the filament down, since it is trying to fit a 2.2mm object through a 2mm hole. This in-turn, causes the gears to erode the filament causing the notch many people are seeing in their jammed filament.

The third image shows a piece of nylon cleaning filament I used to do a cold-pull from my extruder after a clog. As you can see in the image, the filament residue that was pulled from the hotend is not close to the nozzle, but is in fact aligned with where the bore change happens in the heatbreak. This confirmed for myself, that the heatbreak theory was likely the culprit of my continuous clogging.

I solved the problem by buying a standard E3d v6 1.75mm heatbreak and replacing the Prusa heatbreak (Make sure you use Thermal Paste on the heat sink side). So far, I've done two successful 12 hour long prints with no issues. I used the same Filamentum "Crystal Clear" PLA and ran it at standard Temps with 0.8mm retraction, the same settings that were causing my previous clogs. I was able to print all of the same G-code that had previously failed at about the 3-4 hour mark with complete success. I'm now starting a 48 hour print and expect it to work without any issues.

I hope this helps others, as I was in a bad spot for the past 2 weeks. I bought my Prusa kit for business purposes, and the clogging was causing me to have issues with a client I was making prototypes for. I hadn't even considered I would have problems with a brand new machine and miss key deadlines due to it being inoperable when I took the job. Here are some of the failed prints after the 3-4 hour mark, I would show you images of the completed prints but due to the intellectual property of the designs I can not.

I know this is a long post, just wanted to be thorough with the explanation so others can resolve their problem in a timely manner. If you don't plan to use the Multi-Material feature of the Prusa, then this solution should work for you. It might even work with the upgrade, I don't have he MMU 2.0 so i can't say for sure.

Here is the link to the Youtube video if anyone is interested, I wouldn't recommend their oiling solution, but to each their own.

Also I have a i3 MK3s Prusa kit, the heatbreak should solve the problem for everyone with the MK3s and the MK3 who are experiencing this type of clogging

Very interesting!

What I did seemed to have fixed my problem, but maybe there's more than one solution to this issue!

I've successfully printed a 30 hour print since fixing my problem and it came out perfect!

I guess it wouldn't hurt to try the sanding first if you have the tools and don't want to spend money on a new heatbreak. But really, Prusa should be the one sending out the correct parts, whether it be heat breaks, or correct dimension printed parts.

I've submitted my solution to them, whatever the solution turns out to be I hope they can push the fix out quick and perhaps send some of us with bad parts the correct stuff to fix our problems!