Re: MK3S stops extruding mid print (filament grinding)

Now, moving on to a non-benchy print *finally* I've noticed yet another issue. I have some theories on how I can fix it but I'll post it here anyway just incase somebody has seen this before and has suggestions so I can cut to the chase.

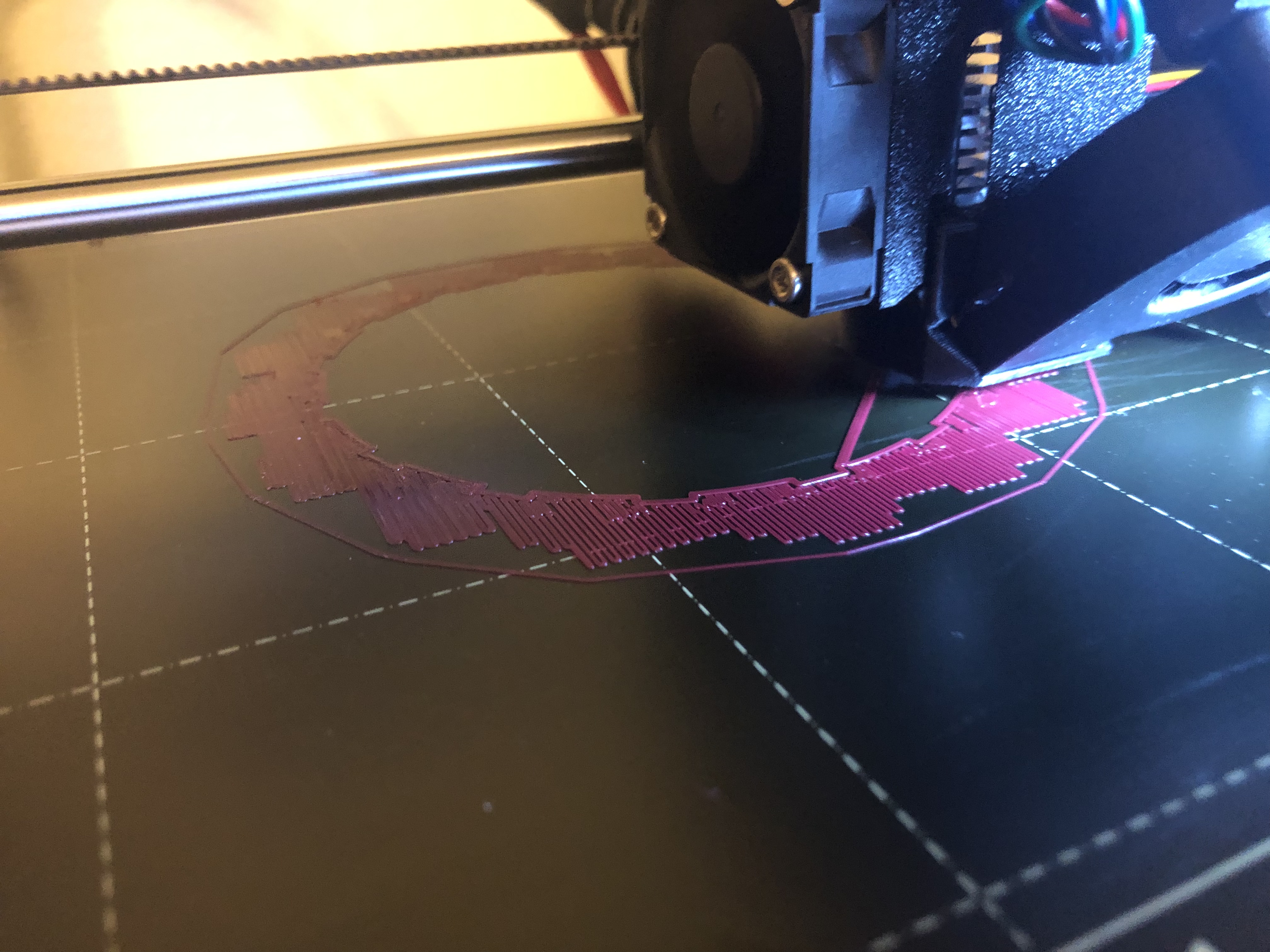

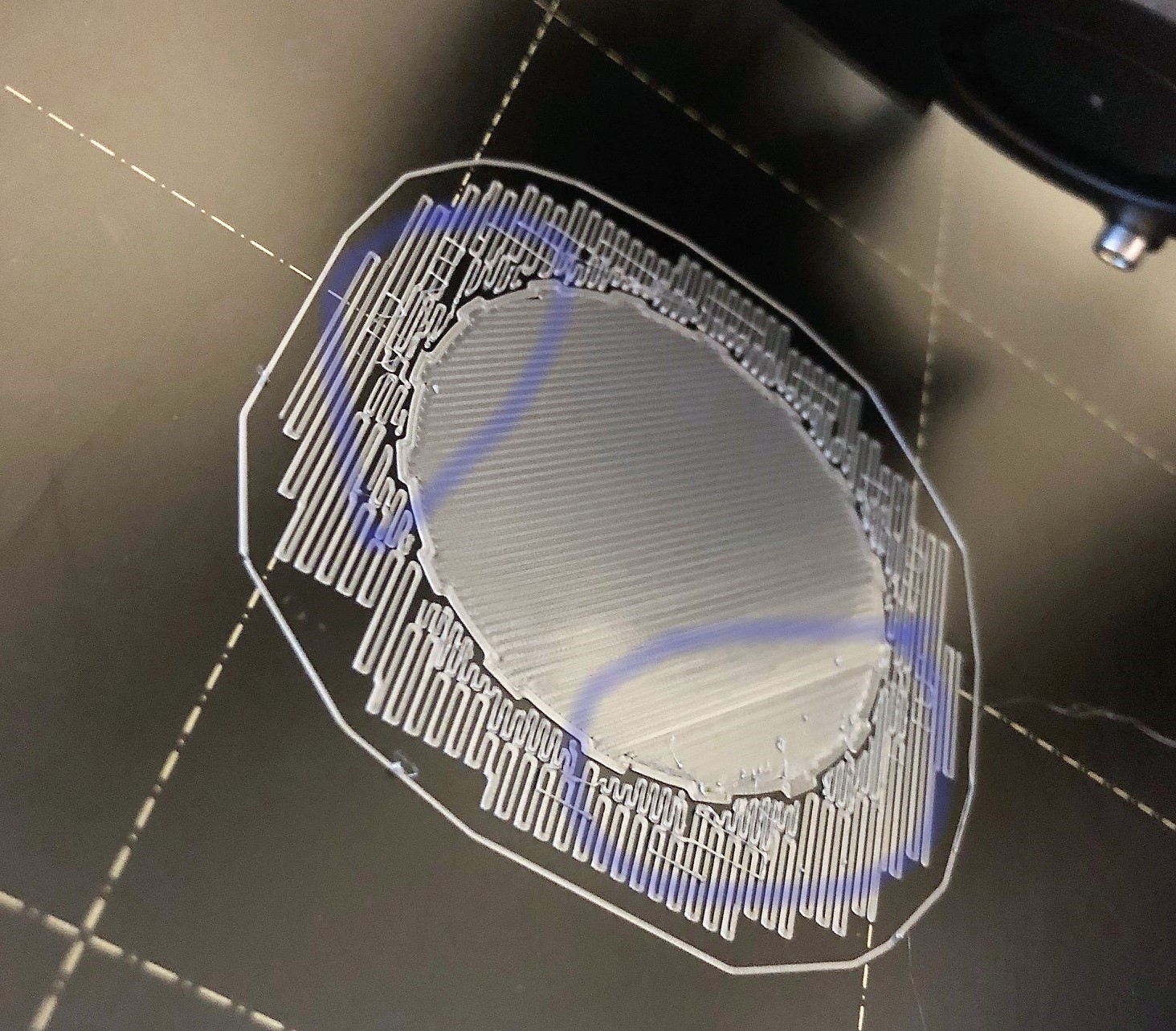

Basically the first layer of support going down starts off decent (as you can see toward top left side of image) then the supports start to peel off the bed when the extruder makes a turn (right side of image).

I tried live adjusting Z which sort of helped, but still happening. I cleaned the surface of the PEI sheet and reapplied glue from the provided glue stick to no avail. I adjusted the X/Y speed and jerk settings (X -200 speed, Y -200 speed, and -2 jerk for both X and Y) which again, sort of got better, but still gave me the results you see in the image. It almost seems like the extruder is taking the turns so quickly that the edges on turns aren't adhering properly.

The last thing I thought of trying which I haven't yet is to boost the bed's heat up to maybe 70-80 instead of the standard 60 for PLA.

Any other suggestions y'all have for maybe fixing this first layer issue?

first layer support fail.jpg

i've had that happen too, i haven't found a solution but i just let it run and it prints fine

Thanks for the insight, it kind of irks me so hopefully there's a real solution, but if you say it eventually works out anyway I may let the print run.

Re: MK3S stops extruding mid print (filament grinding)

The adhesion issue is a common one and easy to fix. A good scrub with dish washer detergent and rinse heavily and then an IPA clean. Never ever touch the PEI surface with your fingers and you will find you can put the glue away until you want to print PETG. Ensure the IPA is very pure 99% and your good to go. IPA clean between prints and detergent clean when you need to.

I still prefer to use Acetone for a deep clean of the surface because it is quick and easy and works for me.

The scaled benchy looks like a good print. Baffled as to why the 0.1mm benchy failed though.

I am concerned the 0.1mm failed. It should of worked without problem.

Things i would do before trying to print in the enclosure would be to get rid of the PLA tube. PLA's co efficient of friction is poor so not a good choice for the filament to slide through. Ensure you eliminate all resistance from the filament path and have it as direct as possible(I think you have probably already done this) Try and alter your spool holder so you have a roller to minimize resistance. I have one set up with 608 bearings which are cheap and readily available. With the spool holder you have the spools can have a tendency to start rocking back and forth during prints that can have lots of retractions in a short space of time. This can cause a yanking motion on the filament that is transmitted straight to the extruder. At the very least this can cause print quality issues but could be contributing to your issues here. When printing with PLA always have the door open on the enclosure. The Prusa machines are very critical with the adjustment of the pressure put onto the filament through the extruder gears so get that setting absolutely perfect.

In saying all this i'm still not convinced that there is not a mechanical problem with your machine. I was expecting that after that big benchy the 0.1mm benchy would just print without issue. Your machine just seams a little sensitive to anything that is not 100% perfect.

Re: MK3S stops extruding mid print (filament grinding)

The adhesion issue is a common one and easy to fix. A good scrub with dish washer detergent and rinse heavily and then an IPA clean. Never ever touch the PEI surface with your fingers and you will find you can put the glue away until you want to print PETG. Ensure the IPA is very pure 99% and your good to go. IPA clean between prints and detergent clean when you need to.

I still prefer to use Acetone for a deep clean of the surface because it is quick and easy and works for me.

The scaled benchy looks like a good print. Baffled as to why the 0.1mm benchy failed though.

I am concerned the 0.1mm failed. It should of worked without problem.

Things i would do before trying to print in the enclosure would be to get rid of the PLA tube. PLA's co efficient of friction is poor so not a good choice for the filament to slide through. Ensure you eliminate all resistance from the filament path and have it as direct as possible(I think you have probably already done this) Try and alter your spool holder so you have a roller to minimize resistance. I have one set up with 608 bearings which are cheap and readily available. With the spool holder you have the spools can have a tendency to start rocking back and forth during prints that can have lots of retractions in a short space of time. This can cause a yanking motion on the filament that is transmitted straight to the extruder. At the very least this can cause print quality issues but could be contributing to your issues here. When printing with PLA always have the door open on the enclosure. The Prusa machines are very critical with the adjustment of the pressure put onto the filament through the extruder gears so get that setting absolutely perfect.

In saying all this i'm still not convinced that there is not a mechanical problem with your machine. I was expecting that after that big benchy the 0.1mm benchy would just print without issue. Your machine just seams a little sensitive to anything that is not 100% perfect.

Finally received my PETG order, you think my filament tube should be PETG or what would you recommend?

I just ordered bearings off amazon, and I'm going to print the spool holder's you've mentioned. (Found a few on thingiverse, but feel free to link your particular one if you'd like since you've personally tested it).

I believe you're right about a mechanical problem, I'll keep giving the machine some goes before I contact Prusa as I'm trying to be sure to eliminate ALL user errors before blaming the machine. I'll go with your method of cleaning the PEI sheet then I'll try printing again. So you're saying I shouldn't need a glue stick at all for PLA prints as long as the sheet is immaculately clean?

Re: MK3S stops extruding mid print (filament grinding)

Yeah you don't need anything for PLA. If the bed is properly clean it sticks amazing to the PEI.

PETG sticks too well and the glue stick actually provides separation layer. Some people use window cleaner as a bed cleaner for PETG because it leaves a little residue to stop the PETG sticking to well

My spool holder is a personal design although very simple. It is similar to this https://www.thingiverse.com/thing:2162266

Was the failure on the 0.1mm benchy a filament grinding issue again.

Re: MK3S stops extruding mid print (filament grinding)

PTFE, Nylon, ABS or PETG in that order would be best for the filament tube. I did a quick search to try and get some figures for PLA and PETG. Could only find figures for PET, ABS and nylon. If PET and PETG are similar then PETG should be an improvement over PLA and reduce friction.

Re: MK3S stops extruding mid print (filament grinding)

PTFE, Nylon, ABS or PETG in that order would be best for the filament tube. I did a quick search to try and get some figures for PLA and PETG. Could only find figures for PET, ABS and nylon. If PET and PETG are similar then PETG should be an improvement over PLA and reduce friction.

I actually have spare PFTE tubing that's pretty long, so I'll use that within the PLA channel I currently have and just print a small bracket to hold it in place.

I don't even know what happened to the .1mm print, I'll try again later and see. I'm willing to bet there's a minor clog from all the BS that's been happening the last few prints and .1mm may have been the threshold to fail with. Anyway I'll try again and observe closely this time.

Thanks a lot for all your help man, glad we hashed it out early, you've been tremendous this entire time!

Re: MK3S stops extruding mid print (filament grinding)

Are you against this type of spool holder?

https://www.thingiverse.com/thing:2047554

Let's assume its bolted/taped down so it won't move from its spot, this appears to be popular and easy to print.

Re: MK3S stops extruding mid print (filament grinding)

PTFE, Nylon, ABS or PETG in that order would be best for the filament tube. I did a quick search to try and get some figures for PLA and PETG. Could only find figures for PET, ABS and nylon. If PET and PETG are similar then PETG should be an improvement over PLA and reduce friction.

I actually have spare PFTE tubing that's pretty long, so I'll use that within the PLA channel I currently have and just print a small bracket to hold it in place.

I don't even know what happened to the .1mm print, I'll try again later and see. I'm willing to bet there's a minor clog from all the BS that's been happening the last few prints and .1mm may have been the threshold to fail with. Anyway I'll try again and observe closely this time.

Thanks a lot for all your help man, glad we hashed it out early, you've been tremendous this entire time!

Don't know if you printed it with the glittery filament or not but best not to use the low layer heights with them.

Haha yeah glad we buried the hatchet. Has been a real mission to try and get it sorted. Not sure if it's there yet but definitely some progress.

Re: MK3S stops extruding mid print (filament grinding)

Are you against this type of spool holder?

https://www.thingiverse.com/thing:2047554

Let's assume its bolted/taped down so it won't move from its spot, this appears to be popular and easy to print.

I believe that type works really well and is nice and simple.

Using your old PTFE tube should work fine.

Re: MK3S stops extruding mid print (filament grinding)

PTFE, Nylon, ABS or PETG in that order would be best for the filament tube. I did a quick search to try and get some figures for PLA and PETG. Could only find figures for PET, ABS and nylon. If PET and PETG are similar then PETG should be an improvement over PLA and reduce friction.

I actually have spare PFTE tubing that's pretty long, so I'll use that within the PLA channel I currently have and just print a small bracket to hold it in place.

I don't even know what happened to the .1mm print, I'll try again later and see. I'm willing to bet there's a minor clog from all the BS that's been happening the last few prints and .1mm may have been the threshold to fail with. Anyway I'll try again and observe closely this time.

Thanks a lot for all your help man, glad we hashed it out early, you've been tremendous this entire time!

Don't know if you printed it with the glittery filament or not but best not to use the low layer heights with them.

Haha yeah glad we buried the hatchet. Has been a real mission to try and get it sorted. Not sure if it's there yet but definitely some progress.

Used the flat purple red filament by fillamentum but I’ll try again with the stock Prusa silver to be sure.

I did however figure out my problem with the first layer supports! Cleaned the bed with acetone, then boosted bed temp to 75 and viola, the first layer stuck near perfectly! Check it out:

Re: MK3S stops extruding mid print (filament grinding)

Are you against this type of spool holder?

https://www.thingiverse.com/thing:2047554

Let's assume its bolted/taped down so it won't move from its spot, this appears to be popular and easy to print.

I believe that type works really well and is nice and simple.

Using your old PTFE tube should work fine.

Sweet, gonna get it done soon. I’ll report back tomorrow or after on the .10mm benchy with the Prusa PLA.

All in all it seems mostly everything is working as intended. Hoping to post a nice honeycomb vase tomorrow morning (Texas time). Praying this 7 hour print won’t fail, it’ll be the first real print out of this baby!

Re: MK3S stops extruding mid print (filament grinding)

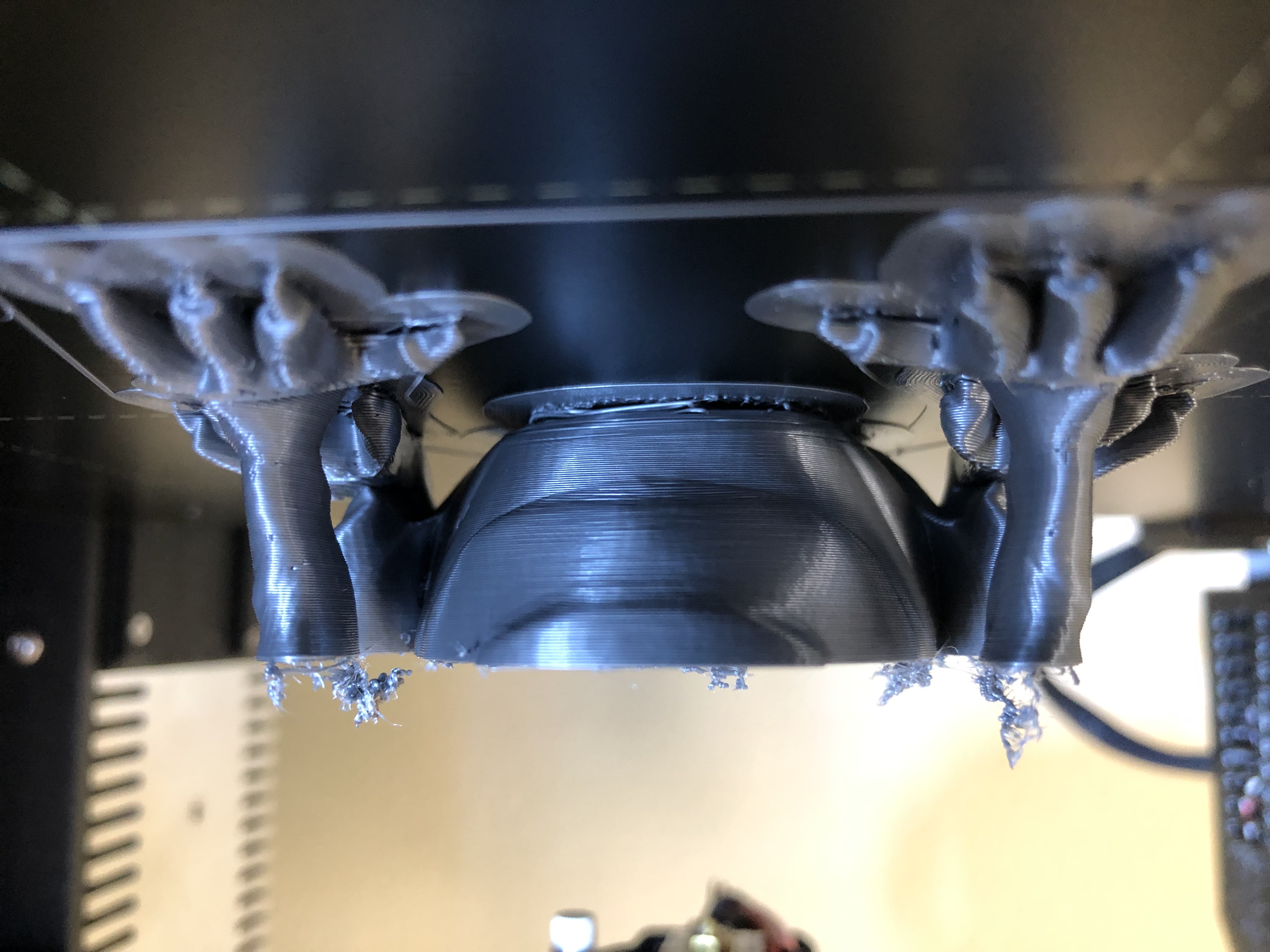

I definitely marked this done way too soon. I started the dragon print from the stock prints on the SD card after doing a cold pull on the extruder. Just wanted to make sure there wasn’t any debris or anything in the hot end. Cleaned the bed with acetone, used the silver Prusa PLA, and then this happened.

Super frustrating. I’m ready to be able to print with my NEW printer. Going to contact support today.

Re: MK3S stops extruding mid print (filament grinding)

I definitely marked this done way too soon. I started the dragon print from the stock prints on the SD card after doing a cold pull on the extruder. Just wanted to make sure there wasn’t any debris or anything in the hot end. Cleaned the bed with acetone, used the silver Prusa PLA, and then this happened.

A59E48E0-3C16-49C2-9989-9CF44EF01DBE.jpeg

CBF49100-F8B4-4703-8D17-1956F05B7143.jpeg

C860BF96-5C28-4FDF-8776-AAB1D953B009.jpeg

Super frustrating. I’m ready to be able to print with my NEW printer. Going to contact support today.

My apologies for the upside down and sideways photos, these were posted from my phone.

Re: MK3S stops extruding mid print (filament grinding)

Spoke to customer support. Unfortunately couldn't proceed far since they needed me to be at my printer so they can have videos of certain things. I guess I'll update this post later once I've come to a conclusion.

Still betting the extruder gear is not aligned perfectly and is causing extrusion issues.

Re: MK3S stops extruding mid print (filament grinding)

Possible clue that I missed is all prints are failing at similar heights. Not exactly but in the ball park to each other.

I wonder if you have an intermittent fault specifically a damaged wire that goes high resistance or open circuit at a certain height.

It just goes from printing great to complete failure in a very short space of time.

Set the nozzle temperature to 220 and then using the move axis feature drive the head to the centre of the X axis and then take the head up and down slowly in the Z looking for dips in nozzle temperature. Then do the same but with the X axis driven to the extreme right. I wouldn't expect to see a shift in excess of 5 degrees.

It could be a painful exercise but if you can be there when the print fails then you can check for basic things like the temperatures reading what they should or any noises coming from the extruder. You might only have a very small time window to actually see any changes that are causing the failure.

When you do get this thing resolved this thing is going to put out awesome prints because you have checked and fine tuned virtually every part.

Re: MK3S stops extruding mid print (filament grinding)

Possible clue that I missed is all prints are failing at similar heights. Not exactly but in the ball park to each other.

I wonder if you have an intermittent fault specifically a damaged wire that goes high resistance or open circuit at a certain height.

It just goes from printing great to complete failure in a very short space of time.

Set the nozzle temperature to 220 and then using the move axis feature drive the head to the centre of the X axis and then take the head up and down slowly in the Z looking for dips in nozzle temperature. Then do the same but with the X axis driven to the extreme right. I wouldn't expect to see a shift in excess of 5 degrees.

It could be a painful exercise but if you can be there when the print fails then you can check for basic things like the temperatures reading what they should or any noises coming from the extruder. You might only have a very small time window to actually see any changes that are causing the failure.

When you do get this thing resolved this thing is going to put out awesome prints because you have checked and fine tuned virtually every part.

I’ve been dreading it but I thought I should print something and sit in front of the printer to watch it fail lol. I like the idea of checking the axis and temperature, that seems like something that would take a lot less time to test.

I have looked at the temperature graph octoprint provides to see any major dips and it seems pretty consistent throughout, but who knows.

I sure hope once this is all resolved it gives me amazing prints because I’ve looked forward to buying an MK3 for months and this has just been so disappointing. I know it’s not Prusa or the mk3’s fault but man am I bummed.

Re: MK3S stops extruding mid print (filament grinding)

Couple of things.

In the picture of the last benchy you printed it looks like the last few mm of the model are getting more shiny. Is that just the light giving that effect or is it actually there. This print also looks like it got further than any of the other prints or is it about the same.

It will probably string like crazy but for a test turn off the retraction completely.

I had another read through the thread but didn't see it mentioned(i only skimmed through). Is it PE Slic3r and are the settings standard.

If the retraction speed is to fast it can cause grinding although quite rare to see this. Standard settings should be fine.

Are you able to look down the PTFE tube and see any deformation. Again i have seen Slightly damaged/deformed PTFE tubes give similar symptoms. If you have any it could be worth changing it to rule it out. Also ensure the PTFE tube is completely and fully pushed home into the hot end.

If i think of anything else i will chime in again.

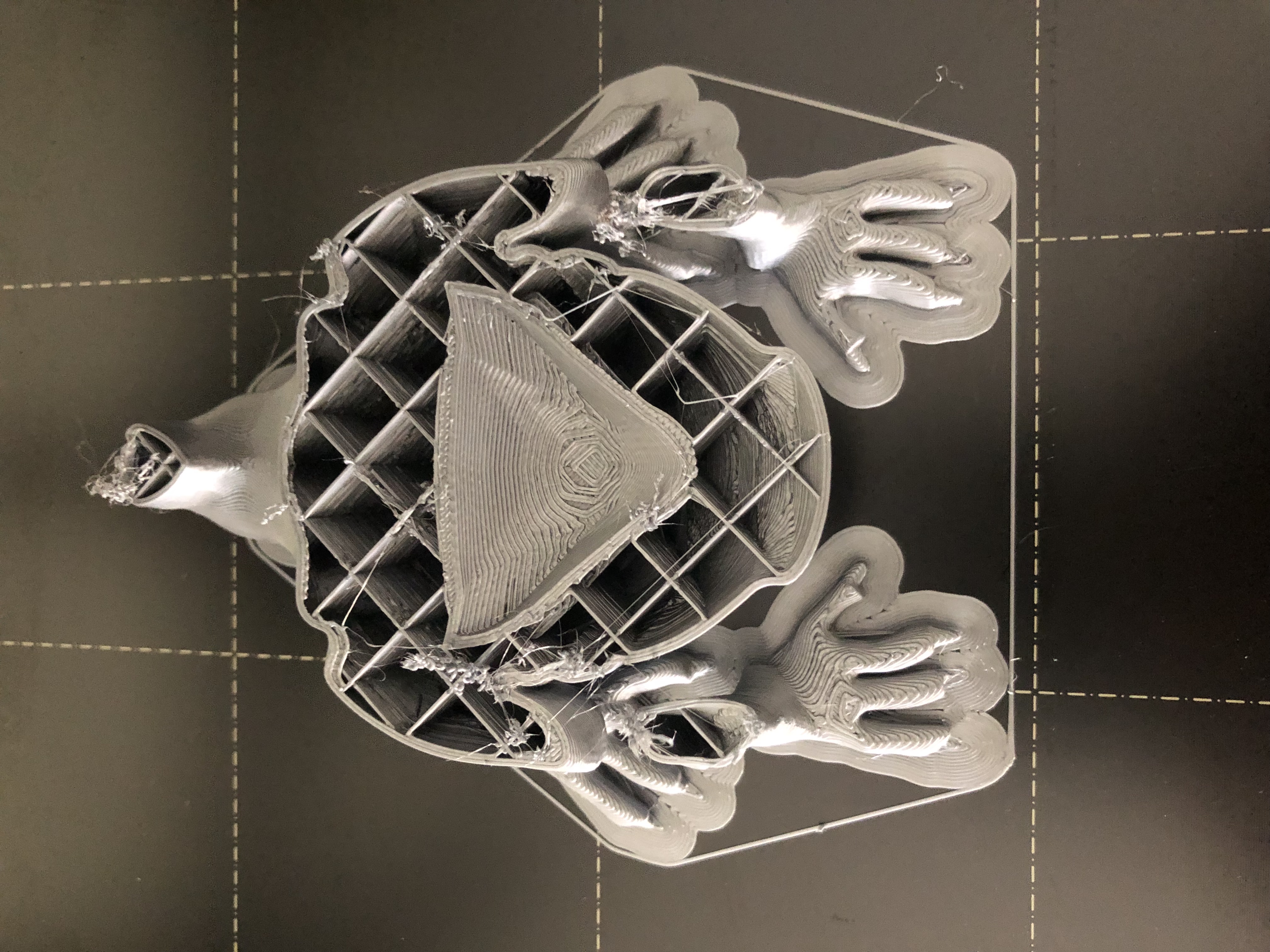

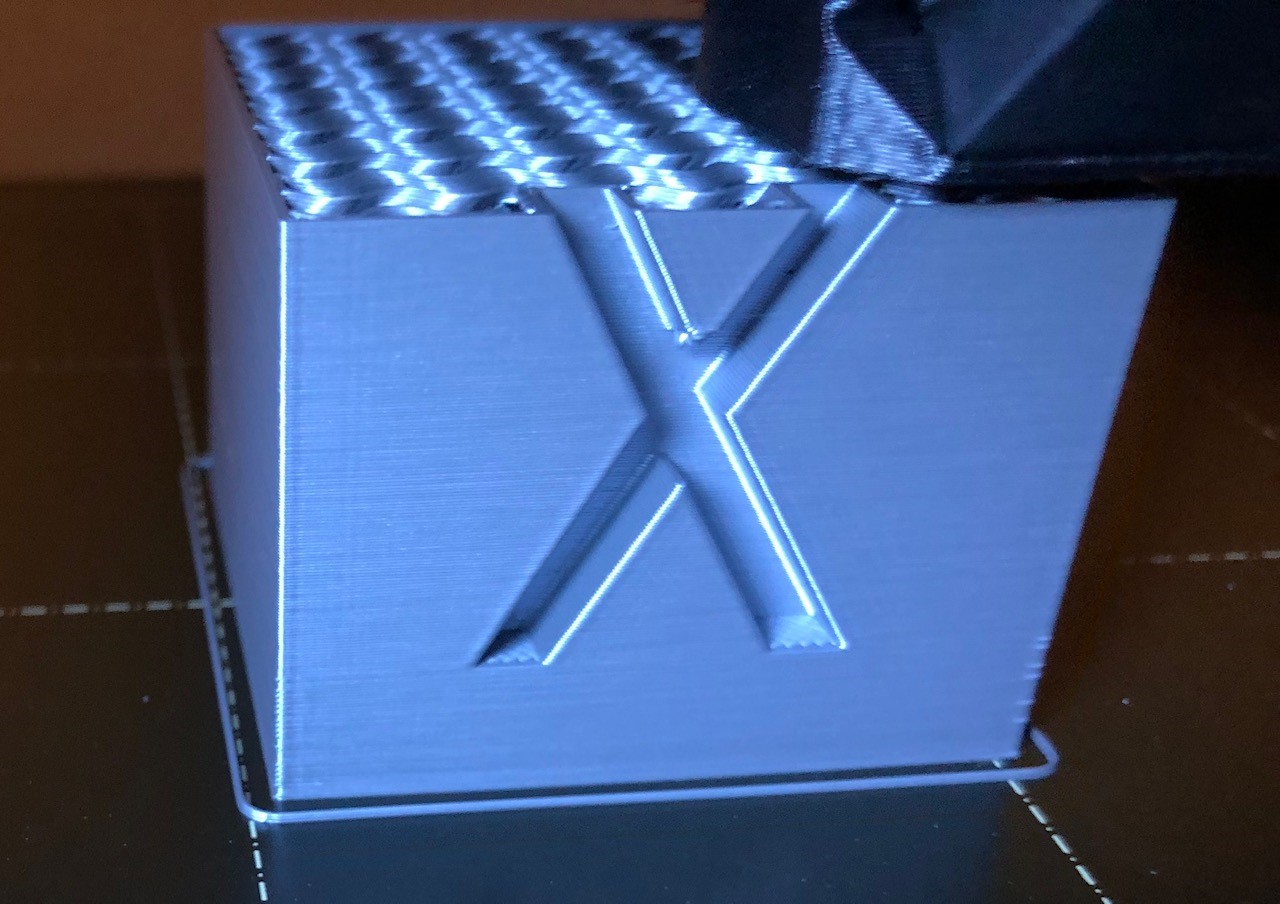

So one thing I haven't really tried yet is turning off retraction completely and I think this may be sort of leading to my issues. After printing a calibration cube last night, which has minimal amounts of retraction to begin with, the print succeeded. There was some visible scarring on the top of the cube but that's for another trouble shooting session that I'm less interested in doing right now because its probably slightly easier to figure out. Here's the cube:

One thing I'm adding up is that the more retraction and z-hop's in prints, the more likely my filament is to grind. Again this leads me to the conclusion that the extruder gear is pushed too hard against the filament. Here's why:

I printed a smaller honeycomb vase after a successful calibration cube just to see what would happen. I watched the print for about 5 minutes and luckily, it had begun to fail in front of my very eyes. What I noticed is that when the filament is constantly retracting back and forth in the same small section of filament (it was printing supports at the time), I believe it is grinding down the filament slowly. I may also add that I've realized the top of the PTFE tube is slightly touching the extruder gear as well, probably causing minimal amounts of debris - enough to mess with it being able to drive filament down no doubt. Other threads with people assembling MK3S's are seeing the same issues with their PTFE tube and extruder gear aligntment.

I've attached the print that failed, highlighting the area's of quick/often retractions as I've observed during print:

This print stopped extruding any filament precisely after printing areas of heavy retraction (not retraction distance, but how often it's retracted in a short period of time).

Re: MK3S stops extruding mid print (filament grinding)

Are you against this type of spool holder?

https://www.thingiverse.com/thing:2047554

Let's assume its bolted/taped down so it won't move from its spot, this appears to be popular and easy to print.

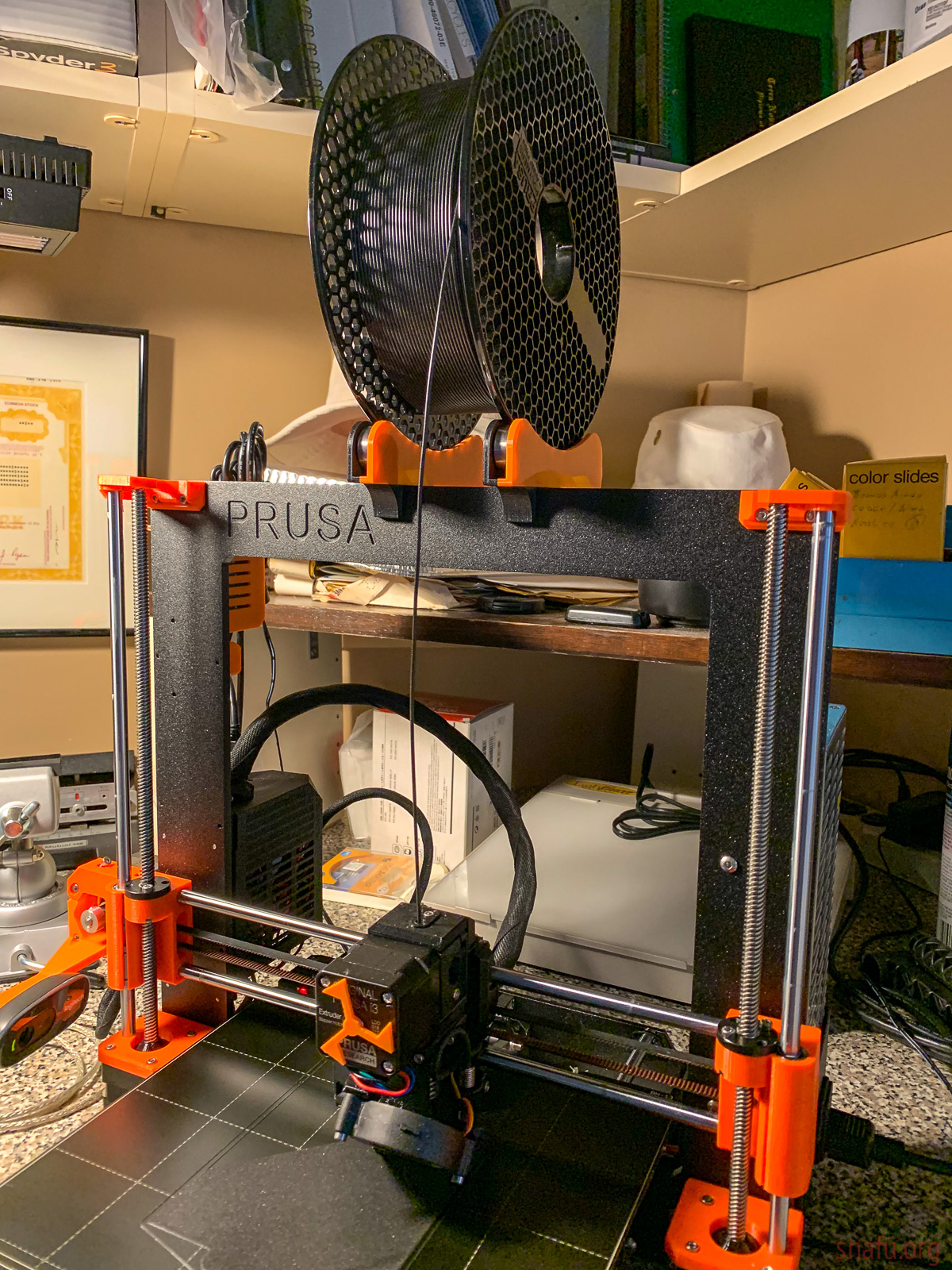

There is a mod of TUSH so it will mount to the top rail of an i3 machine. https://www.thingiverse.com/thing:2047554

I printed it for my MK3S. It works quite well. I don't know if it makes a difference on my MK3S. The non-Prusa version certainly improved print quality when used with my CR-10S.

Since taking that picture I've added a matching filament guide.

Re: MK3S stops extruding mid print (filament grinding)

Are you against this type of spool holder?

https://www.thingiverse.com/thing:2047554

Let's assume its bolted/taped down so it won't move from its spot, this appears to be popular and easy to print.

There is a mod of TUSH so it will mount to the top rail of an i3 machine. https://www.thingiverse.com/thing:2047554

I printed it for my MK3S. It works quite well. I don't know if it makes a difference on my MK3S. The non-Prusa version certainly improved print quality when used with my CR-10S.

p-1615-IMG_3844.jpg

Since taking that picture I've added a matching filament guide.

Awesome, I've received my bearings today, and will eventually print this out. For now I need to get my problem sorted out lol.

Re: MK3S stops extruding mid print (filament grinding)

Well this is awkward.... Live chat couldn't even help me. They referred me to the prusa email, which I just did. Hoping all the reviews I've read online about Prusa never responding/taking forever isn't true.