Re: MK3S stops extruding mid print (filament grinding)

Before you take apart the hotend, print a few collet clips. Your PTFE may be lifting up, leading to the jam.

Print a half dozen or so, so that you can lose a couple, and they have time to cool between layers.

After you inspect the PTFE...

Lift the collet.

Push the new/old PTFE in as far as you can.

Insert the collet clip under the collet.

Boom! No more moving PTFE.

Re: MK3S stops extruding mid print (filament grinding)

This is a very good tip.

I have a slightly different method that works but technically the insertion of the collet will guarantee no movement and is a better solution to my method.

Re: MK3S stops extruding mid print (filament grinding)

Before you take apart the hotend, print a few collet clips. Your PTFE may be lifting up, leading to the jam.

Print a half dozen or so, so that you can lose a couple, and they have time to cool between layers.

After you inspect the PTFE...

Lift the collet.

Push the new/old PTFE in as far as you can.

Insert the collet clip under the collet.

Boom! No more moving PTFE.

Guys, I think this may be it... my PTFE at the top is semi grinded, seemingly because it keeps moving up during prints and I’ve pushed it down multiple times now! You’re definitely on to something!!

Question is does the collet usually come standard or is this usually an addition people buy/print. Mine didn’t come with one. I’m disassembling the hot end here pretty soon so I can put the new PTFE in and clean out any loose debris. I’ll print a collet before I do it tho, genius idea!

Re: MK3S stops extruding mid print (filament grinding)

Fingers crossed this is it.

If the PTFE tube has been rising up then that could certainly be your issue.

This style of quick connector that E3D use are normally very good and are extensively used for air lines and the like but you do have to be firm when pushing tube into them.

The collet is a modification. It holds the release ring in the fully open position when fitted. I would call it an insurance policy but the most important bit is that the PTFE tube is pushed fully home and then fit the collet.

Re: MK3S stops extruding mid print (filament grinding)

I have just upgraded my MK3 to MK3S using the official kit. And I do see similar issue. I am not even able to load filimanet, if I don't cut it's front at 45deg. It will always get stuck on the edge of PTFE tube (tube is oriented correctly). It almost looks like the Bondtech gear is way too much over the center axis. Interestingly, also bed leveling results has changed dramatically. I will try to talk to the support.

Re: MK3S stops extruding mid print (filament grinding)

It is a mystery that prusa does not include these search thing verse no need to buy them Blue is the size for Prusa printers

https://e3d-online.com/collet-clips-pack-of-2

Re: MK3S stops extruding mid print (filament grinding)

So I’ve disassembled the hot end, air dusted it, realigned the bracket that goes on the extruder gear side (just Incase), and used a new PTFE tube with freshly printed collet. I made sure to push down all the way and install the tube in the correct direction before putting the collet on to “lock” it into place.

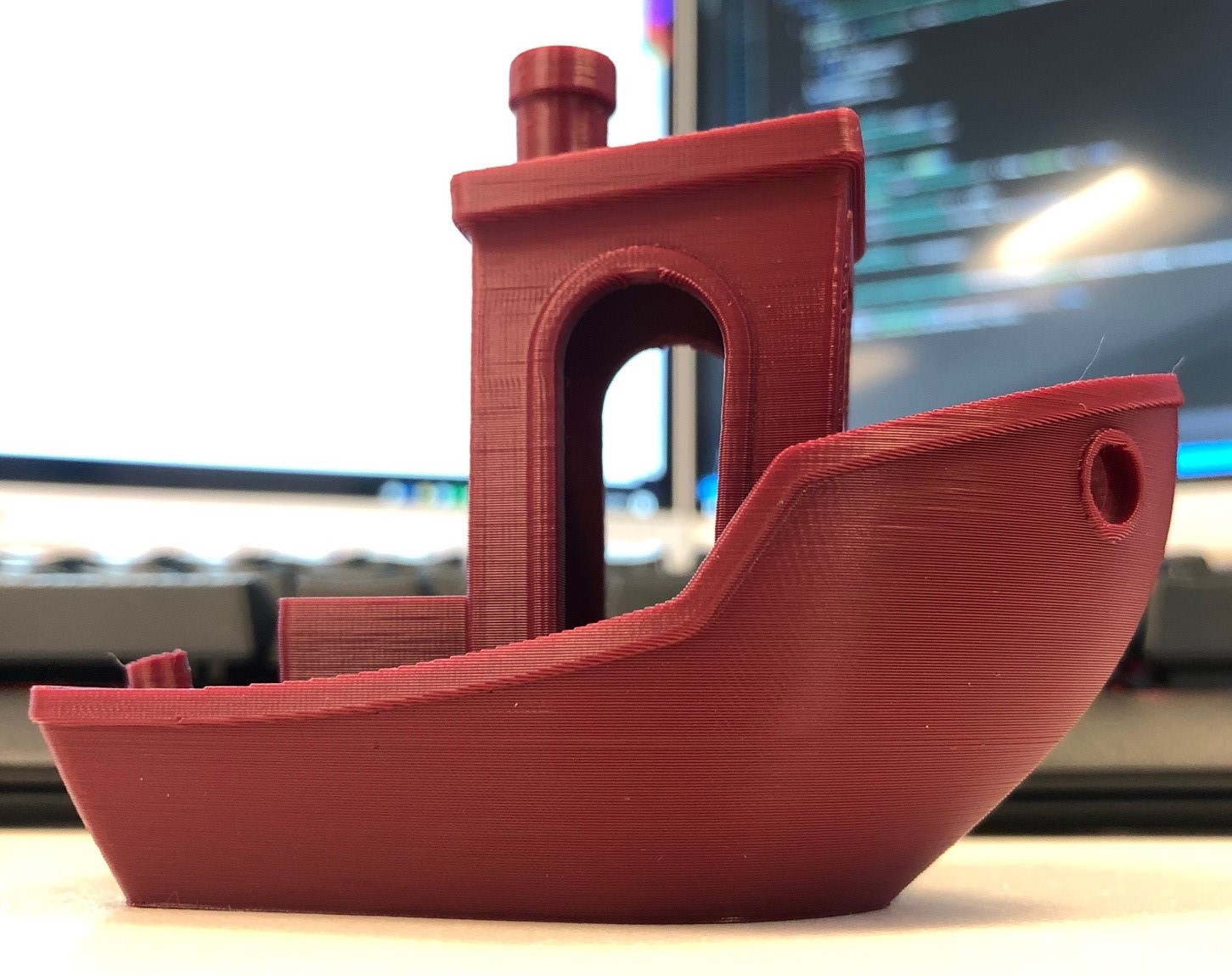

Here’s a photo of the old PTFE with obvious grind marks. Just started a new benchy, here’s to hoping it works!

Re: MK3S stops extruding mid print (filament grinding)

I have just upgraded my MK3 to MK3S using the official kit. And I do see similar issue. I am not even able to load filimanet, if I don't cut it's front at 45deg. It will always get stuck on the edge of PTFE tube (tube is oriented correctly). It almost looks like the Bondtech gear is way too much over the center axis. Interestingly, also bed leveling results has changed dramatically. I will try to talk to the support.

Ok so I wasn’t going crazy when I thought the extruder gear was way too close to the PTFE... if my print fails again after doing what I did in the post before this, I’m hoping support realizes the mistake quickly and fixes it! I’ve been super excited about finally buying a Prusa for months, and I’m super bummed out I’ve had it for over a week and can’t print anything.

Re: MK3S stops extruding mid print (filament grinding)

Update: after all that, print failed. I’m convinced the printed part that “aligns” the extruder to the E carriage parts is slightly off by a few MM. Filament is grinding too hard off the extruder gear. My prediction is that the extruder gear is pushing against the filament too tightly. I tightened the idler door to about 2-3 threads (basically as much as I could muster without it slipping off) so I can rule out that the idler door is too tight. Used the stock benchy gcode.

Last attempt is to turn off retraction and see if it makes a difference since less malleable filament is coming back up to the “too tight” extruder gear.

Re: MK3S stops extruding mid print (filament grinding)

Do Prusa support reply to threads on the forums or is this mostly a community ran forum? Wondering if I got a bad printed part in my kit and if so how I can get it replaced. Based off somebody else’s reply, the mk3s parts may slightly be off by a bit.

Re: MK3S stops extruding mid print (filament grinding)

Do Prusa support reply to threads on the forums or is this mostly a community ran forum? Wondering if I got a bad printed part in my kit and if so how I can get it replaced. Based off somebody else’s reply, the mk3s parts may slightly be off by a bit.

Prusa reps seldom post here this is user to user support.

contact prusa online chat system for 24/7 support this will be far more effective than using Email.

log into your account on one of the prusa store pages and in the bottom right corner you will see the Chat system box click in it enter your Invoice number for you Prusa and start the chat system they do an excellent job and will take good care of you.

Re: MK3S stops extruding mid print (filament grinding)

Your not left with that many options but there are a few.

Ensure the Noctua fan is facing the right direction. I would also consider replacing this fan. The seft test checks if it's spinning but not the speed unless something has been introduced in the latest printers/firmware.

Check your spool is not getting jammed and it rotates freely.

There was an issue where a pin was able to move on some printers in relation to the bondtech extruder. I cannot remember if the fix was to print new parts, shim it or fit a longer pin.

I've had a look through the build manual to try and see if there are many opportunities for assembly of the hot end to go wrong. There are a couple of opportunities but not sure if they would directly cause your problem. In saying that I would be tempted to do a complete strip and rebuild from the manual.

After that I might actually be out of ideas.

Re: MK3S stops extruding mid print (filament grinding)

Your not left with that many options but there are a few.

Ensure the Noctua fan is facing the right direction. I would also consider replacing this fan. The seft test checks if it's spinning but not the speed unless something has been introduced in the latest printers/firmware.

Check your spool is not getting jammed and it rotates freely.

There was an issue where a pin was able to move on some printers in relation to the bondtech extruder. I cannot remember if the fix was to print new parts, shim it or fit a longer pin.

I've had a look through the build manual to try and see if there are many opportunities for assembly of the hot end to go wrong. There are a couple of opportunities but not sure if they would directly cause your problem. In saying that I would be tempted to do a complete strip and rebuild from the manual.

After that I might actually be out of ideas.

Update:

Noctua fan is facing right direction, sticker facing extruder. Seems its running well, doesn't appear to be anything wrong with it but I wouldn't know exact rpm of it.

Ok biggest breakthrough is from your second suggestion. I was able to get a single successful print with your advice.

Kind of a rookie mistake on my part but the hole I made in the top of the enclosure that I was feeding filament through was actually pretty far ahead of the extruder. It was built/designed with my old printer in mind so when I first put the Prusa into the enclosure, I noticed the filament was kind of snagging on the corner of the hole (I did print a tube for it to go through so it wasn't exposed to dust, etc).

This filament passway is about 6-8 inches closer to the front of the enclosure while the prusa's extruder was toward the center of the enclosure. I deemed it OK when I put the Prusa in because I physically pulled on the filament and noticed that there wasn't too much friction. That was my mistake though, because what I didn't add up is the fact that midway through the print, as the extruder got higher, it was actually causing more and more resistance on the filament.

The solution was to move the printer up toward the front of the enclosure, therein aligning the filament passage directly on top of the extruder. Voila, successful print. I also used the stock SD card that came instead of connecting to octoprint.

Without getting too excited, I began another print before I left for work this morning. This time, a bigger benchy to make sure it'll still work. Using PE Slic3r, I scaled to 150% and kept everything at stock prusa settings EXCEPT the temperature. Essentially I was still getting some stringing from 215* PLA temp, and so I tried 210* instead. I'm not sure if it was the temperature that caused the print to fail, or if it was using octoprint/my own sliced model? Literally all the settings on slic3r are default, not a single change except to change the hotend temp to 210. I've printed this PLA at 190-205 so its hard for me to believe that its getting clogged because of a 210 temp.

Here's the photos of both the successful print, as well as the failed 150% scaled benchy (screenshotted from my remote video stream).

Re: MK3S stops extruding mid print (filament grinding)

Do Prusa support reply to threads on the forums or is this mostly a community ran forum? Wondering if I got a bad printed part in my kit and if so how I can get it replaced. Based off somebody else’s reply, the mk3s parts may slightly be off by a bit.

Prusa reps seldom post here this is user to user support.

contact prusa online chat system for 24/7 support this will be far more effective than using Email.

log into your account on one of the prusa store pages and in the bottom right corner you will see the Chat system box click in it enter your Invoice number for you Prusa and start the chat system they do an excellent job and will take good care of you.

Thanks, gonna try a few last couple of measures just to be positive its not a user error, then will be contacting support to see what's going on.

Re: MK3S stops extruding mid print (filament grinding)

Hmmm that is quite interesting. The complete benchy doesn't look to bad although some minor layer issues.

I have a bit of a theory and it is fairly elaborate. You may have several small issues combining to cause the failures.

Try to remove all variables. Remove printer from enclosure and mount spool on the machine with the standard spool holder. I will go out on a limb and i think you will get successful prints. If it works i will write up why i think you are getting the failures and what you can do to get your printer back into the enclosure and printing successfully. It is late here and i have to sleep so don't have time to type it all up but like i said if it works i will go into all the little details that i think are causing your issue.

Another simpler way to possibly prove my theory and means you don't have take the printer out of the enclosure is to put the retraction speed down to 20mm/s and put z hop down to 0.

Was the tube you printed to guide the filament made from PLA?

When the machine is doing it's retractions do you see the spool rocking back and forth or does it just rotate smoothly.

Re: MK3S stops extruding mid print (filament grinding)

Hmmm that is quite interesting. The complete benchy doesn't look to bad although some minor layer issues.

I have a bit of a theory and it is fairly elaborate. You may have several small issues combining to cause the failures.

Try to remove all variables. Remove printer from enclosure and mount spool on the machine with the standard spool holder. I will go out on a limb and i think you will get successful prints. If it works i will write up why i think you are getting the failures and what you can do to get your printer back into the enclosure and printing successfully. It is late here and i have to sleep so don't have time to type it all up but like i said if it works i will go into all the little details that i think are causing your issue.

Another simpler way to possibly prove my theory and means you don't have take the printer out of the enclosure is to put the retraction speed down to 20mm/s and put z hop down to 0.

Was the tube you printed to guide the filament made from PLA?

When the machine is doing it's retractions do you see the spool rocking back and forth or does it just rotate smoothly.

Understood, will report back my findings and get back to you ASAP.

I'll try retraction speed to 20mm/s and z hop down to 0 within the enclosure, then if fail, I'll take it out and print with stock spool holder.

To answer your questions: filament guide is PLA. and when the machine does its retractions i didn't really see it rocking at all, seems to rotate smoothly but I'll keep an eye out for that when I print today.

Re: MK3S stops extruding mid print (filament grinding)

Hmmm that is quite interesting. The complete benchy doesn't look to bad although some minor layer issues.

I have a bit of a theory and it is fairly elaborate. You may have several small issues combining to cause the failures.

Try to remove all variables. Remove printer from enclosure and mount spool on the machine with the standard spool holder. I will go out on a limb and i think you will get successful prints. If it works i will write up why i think you are getting the failures and what you can do to get your printer back into the enclosure and printing successfully. It is late here and i have to sleep so don't have time to type it all up but like i said if it works i will go into all the little details that i think are causing your issue.

Another simpler way to possibly prove my theory and means you don't have take the printer out of the enclosure is to put the retraction speed down to 20mm/s and put z hop down to 0.

Was the tube you printed to guide the filament made from PLA?

When the machine is doing it's retractions do you see the spool rocking back and forth or does it just rotate smoothly.

You’re on to something, mate. I got a successful 150% scaled 208* no stringy, good layer lines benchy over night. Must have been the filament snagging the entire time. Just started up a .10mm benchy just for shits and giggles. So now that it seems we’ve pinpointed the issue, how can I get back into the enclosure?

Re: MK3S stops extruding mid print (filament grinding)

My .10mm benchy failed, but I'm not really too worried about that right now, could be for various reasons and I'm sure I can troubleshoot it myself.

However, here is some photos of my 150% scaled benchy for quality checking.

You'll notice that one of the sides of the benchy has slightly less pretty layers than the other side. I'm sure some fine tuning will fix it and I'm happy to hear suggestions as to how I can achieve that.

Re: MK3S stops extruding mid print (filament grinding)

Now, moving on to a non-benchy print *finally* I've noticed yet another issue. I have some theories on how I can fix it but I'll post it here anyway just incase somebody has seen this before and has suggestions so I can cut to the chase.

Basically the first layer of support going down starts off decent (as you can see toward top left side of image) then the supports start to peel off the bed when the extruder makes a turn (right side of image).

I tried live adjusting Z which sort of helped, but still happening. I cleaned the surface of the PEI sheet and reapplied glue from the provided glue stick to no avail. I adjusted the X/Y speed and jerk settings (X -200 speed, Y -200 speed, and -2 jerk for both X and Y) which again, sort of got better, but still gave me the results you see in the image. It almost seems like the extruder is taking the turns so quickly that the edges on turns aren't adhering properly.

The last thing I thought of trying which I haven't yet is to boost the bed's heat up to maybe 70-80 instead of the standard 60 for PLA.

Any other suggestions y'all have for maybe fixing this first layer issue?

Re: MK3S stops extruding mid print (filament grinding)

Now, moving on to a non-benchy print *finally* I've noticed yet another issue. I have some theories on how I can fix it but I'll post it here anyway just incase somebody has seen this before and has suggestions so I can cut to the chase.

Basically the first layer of support going down starts off decent (as you can see toward top left side of image) then the supports start to peel off the bed when the extruder makes a turn (right side of image).

I tried live adjusting Z which sort of helped, but still happening. I cleaned the surface of the PEI sheet and reapplied glue from the provided glue stick to no avail. I adjusted the X/Y speed and jerk settings (X -200 speed, Y -200 speed, and -2 jerk for both X and Y) which again, sort of got better, but still gave me the results you see in the image. It almost seems like the extruder is taking the turns so quickly that the edges on turns aren't adhering properly.

The last thing I thought of trying which I haven't yet is to boost the bed's heat up to maybe 70-80 instead of the standard 60 for PLA.

Any other suggestions y'all have for maybe fixing this first layer issue?

first layer support fail.jpg

i've had that happen too, i haven't found a solution but i just let it run and it prints fine