[MK3S+] Crash Detection Too Sensitive?

Hi all,

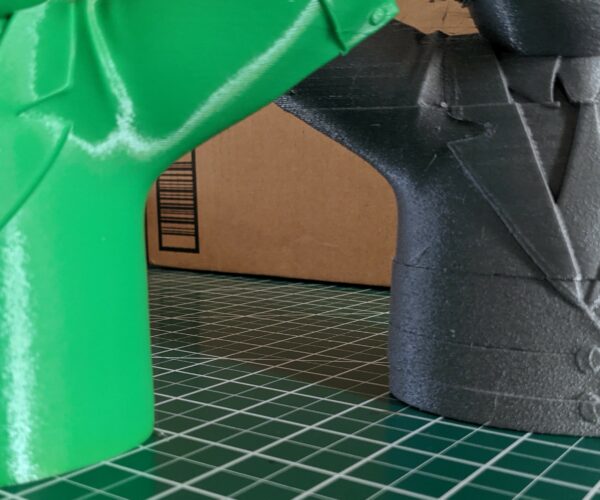

So I've just finished assembling my MK3S+ about a week ago, and while everything works well when I print small low things. When I print something taller than 10mm, I keep running into Y Axis crash detection problems. The belts are clear and tight, everything works great when printing low things... but when I print tall.. I get crash detected..

When I disable crash detection everything just prints fine... Does anyone have any suggestion on how to solve the crash detected issues? I've already try lifting up Live Z, but that didn't help. Also, I'm printing in PETG, maybe it's dragging or just bumping into some of the strands?

Thanks for any help!

RE: [MK3S+] Crash Detection Too Sensitive?

You might as well leave it off. At one point I experienced spurious crash reports, turned it off, and never looked back.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: [MK3S+] Crash Detection Too Sensitive?

Yeah... Been printing without crash detection for years now, what are the chances that the extruder head gets totally destroyed during a fault? 🤣

RE: [MK3S+] Crash Detection Too Sensitive?

Hi all,

So I've just finished assembling my MK3S+ about a week ago, and while everything works well when I print small low things. When I print something taller than 10mm, I keep running into Y Axis crash detection problems. The belts are clear and tight, everything works great when printing low things... but when I print tall.. I get crash detected..

When I disable crash detection everything just prints fine... Does anyone have any suggestion on how to solve the crash detected issues? I've already try lifting up Live Z, but that didn't help. Also, I'm printing in PETG, maybe it's dragging or just bumping into some of the strands?

Thanks for any help!

You say the belts are tight, and crash is on the Y axis, just for curiosity sake. Crash could also be too much resistance in movement on Y axis.

1. Would check belts are not too tight, this can cause a crash, print the test tool and test tension.

2 Are the linear bearings greased correctly? They can run rough if not greased and cause resistance (unlikely but worth checking anyway).

3 Finally check the Y axis rods are parallel, loosen the 4 rod holders (2 back, 2 front) so are just able to move slightly (8 x screws) and move the axis slowly and gently back and forth fully with the power off, then tighten each end in turn when the bed is at the end being tightened. This will set the rods parallel, and also lessen the pressure on the bearings.

Tank you very much!

RE: [MK3S+] Crash Detection Too Sensitive?

@marauderz

You’re not by any chance using grid infill? Its lines cross within each layer, and in my hands it’s been notorious for triggering crash detection. For example, I had a hard time getting some of the presliced gcode files for the Lack enclosure to print until I resliced the STLs with gyroid infill.

From the Prusa Knowledgebase:

”it sometimes can cause annoying noise or even a print failure due to the nozzle going over the crossings where material accumulates.”

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: [MK3S+] Crash Detection Too Sensitive?

After over a year of use, almost everyday, I had one instance of "crash detection". It was on a case where one corner of a print started to warp off the print-plate at a corner and thus raised the print a bit at that corner.

The crash detection allowed me to put a tape on top back to the edge and bring back the print to a better placement and continue to the end. The alternative would probably have the nozzle knock the whole thing off and create a mess.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE

RE: [MK3S+] Crash Detection Too Sensitive?

You say the belts are tight, and crash is on the Y axis, just for curiosity sake. Crash could also be too much resistance in movement on Y axis.

1. Would check belts are not too tight, this can cause a crash, print the test tool and test tension.

2 Are the linear bearings greased correctly? They can run rough if not greased and cause resistance (unlikely but worth checking anyway).

3 Finally check the Y axis rods are parallel, loosen the 4 rod holders (2 back, 2 front) so are just able to move slightly (8 x screws) and move the axis slowly and gently back and forth fully with the power off, then tighten each end in turn when the bed is at the end being tightened. This will set the rods parallel, and also lessen the pressure on the bearings.

1. Belt tension during test is 263, that's not very tight right? Where do I find the printed test tool?

2. Bearings are running smooth.

3. Will have to try this.

Thanks for the suggestions!

RE: [MK3S+] Crash Detection Too Sensitive?

@marauderz

You’re not by any chance using grid infill? Its lines cross within each layer, and in my hands it’s been notorious for triggering crash detection. For example, I had a hard time getting some of the presliced gcode files for the Lack enclosure to print until I resliced the STLs with gyroid infill.

From the Prusa Knowledgebase:

”it sometimes can cause annoying noise or even a print failure due to the nozzle going over the crossings where material accumulates.”

No, I'm using Gyriod infill.

RE: [MK3S+] Crash Detection Too Sensitive?

@marauderz

Here us the belt tension tool, bur 263 sounds about right. Should be 240-300 (275 is recommended) but 263 is fine.

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

Must be printed IN PETG.

Tank you very much!

RE: [MK3S+] Crash Detection Too Sensitive?

@marauderz

Another query, how did the self test, XYZ and Z Calibrations go, did they run successfully?

Tank you very much!

RE: [MK3S+] Crash Detection Too Sensitive?

@marauderz

Another query, how did the self test, XYZ and Z Calibrations go, did they run successfully?

Yes.. Calibrate XYZ reports slightly skewed axes, other than that.. all fine... which is why is maddening that I can't use the feature properly!!

Crash detection *causes* layer shifts

Upgraded from mk3 to mk3s+, also changed the board (long story). I suddenly got X layer shifts on my larger prints. Belt tensions just fine (267, 265), rails clean and lubed... Couldn't figure it out. Finally caught a layer shift due to crash detection (even though it didn't actually crash). Finally tried turning off crash detection and suddenly perfect prints, just like when I first put this thing together! It's too sensitive.

Sure. Nothing new here. I gave up on crash detection a long time ago. Turned it off, never looked back. At least in my hands it caused more problems than it solved. In most cases I traced it back to infill related issue.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: [MK3S+] Crash Detection Too Sensitive?

I recently had the same issue, y axis crash detection immediately resumed print automatically but caused an offset of 1-2mm. This happened at about the same height every time. Checked the unit mechanically and all seems ok. Greased the slides etc. Other threads suggested it might be an over heating Einsy so I used a laser thermometer which read 40 degrees at the top of the EINSY box at the time of the crash. To test this I relocated my piece to the back of the heated bed and measured temp again at 32 degrees. Relocating the model to the rear of the bed pulled the bed out from under the EINSY box and it printed twice with no issues. This tends to confirm the overheating theory because when a crash is detected, the bed moves forward and the extruder lifts up. This would cause the heat source under the EINSY box to be removed, it cools a few degrees almost immediately, the fault goes away and the print resumes. (too bad it resumes offset). By relocating the print the fault goes away so I'm thinking a few cooling holes at the top of the box, a clip on heat deflector to direct bed heat away, or a small fan underneath should cure the issue.

RE: [MK3S+] Crash Detection Too Sensitive?

I am now running PETG (instead of ABS) filament which needs lower bed & extruder temps. I also drilled 2 x 12mm holes in the top of the EINSY door. The crash then offset resume issue has completely gone away. I also swapped the bed heat and extruder heat lines in Slicer so that the bed heats to full temp first while located fully front of the printer, then the much faster extruder heat up starts. (This has the added benefit of drastically reducing drooling out of the print nozzle). The logic is to reduce the time that a hot bed sits under the EINSY box which now seems to operate under 35 deg. instead of over 40 deg. I have removed my aux. colling fan from under the box as it's not needed anymore. I would encourage Prusa to redesign the EINSY enclosure to add more vents on each side of the top to improve cooling air flow along with a deflector on the bottom to guide hot bed air away from the box.

here is the slicer settings I use for the preheat bed first procedure to simply change the order found in

[Printer Settings] [Custom G-Code] ...

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

RE: [MK3S+] Crash Detection Too Sensitive?

Do you mind sharing the modified code? 🙂

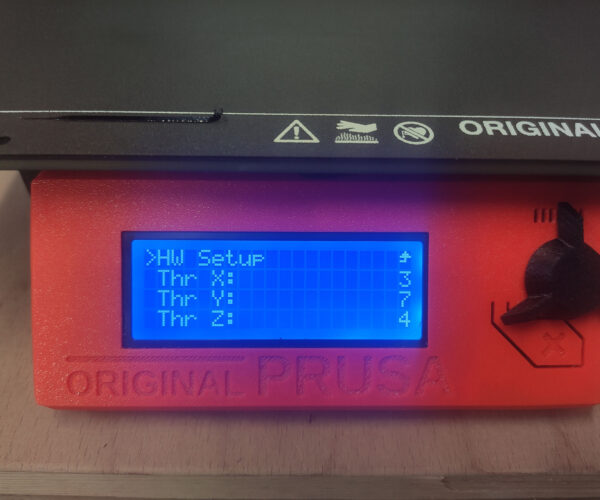

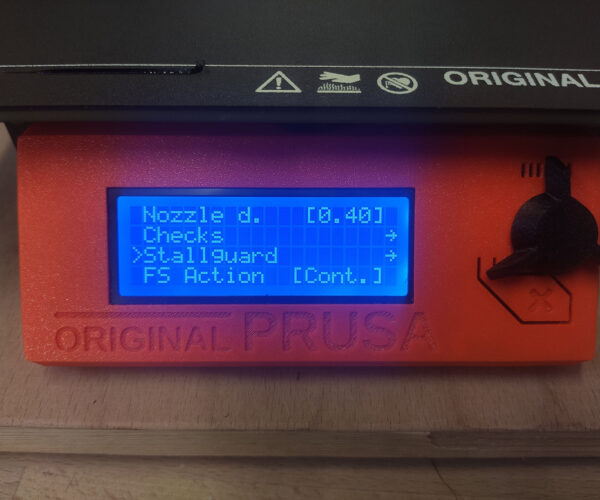

Had the same issues. That's why I started modifying the firmware a little. A stallguard value of 7 for x and y works fine for me.

You can find it on my GitHub account: https://github.com/NightHawk32/Prusa-Firmware/tree/MK3_3.10.0