Mini Flying Spaghetti Monster ...

This is really more of a report and an observation than it is a complaint or request for help ...

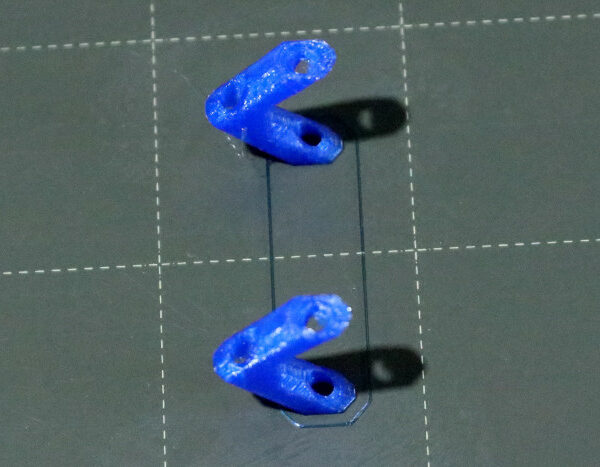

There is this cute 3d printed belt that I am printing in kind of a blue clear filament. It was originally a long print in one piece thing that would take over a day. Since I don't want to let the printer run a whole day, as in when I'm not there, and since I'm actually losing weight (finally! Yes!) I want to be able to take out links, and hopefully never to add them back!

Anyhoo, I broke it all up and converted the round pieces to pins that slide in and out. The links are tricky to print. To do them without support and to get the pin holes round you need to print them standing up, with maybe a 3/8 inch square contacting the plate. I first tested printing one. Beautiful! Then 2-up and again perfect! One-up takes like 35 minutes. 2-up takes 55. Then I figured 4-up so it won't take a month of Sundays to print.

For some reason, when I do 2-up it's perfect! First time, every time, all the time, no boo-boos at all! When I try 4-up, however, never! Spaghetti monster after maybe 1 hour and 15 minute into the 1 1/2 hour print, as in almost done! Curse, wipe, hairspray, try again, same thing, and I'm just gonna finish it all 2-up and not waste more hour and 15 minutes trying yet again.

Anyway, kind of unusual, 2-up prints fine all the time, 4-up, same piece, just the 2-up pattern laid twice side by side.

Oh well, so it goes ... (and so do I). 🙂

title here

Have you tried that option (I forget what it's called) in the slicer(s) to finish one instance of the model before beginning on the others?

@jsw

Sequential printing, Print Setting/Output options/ Sequential printing: (tick the box) complete individual objects

Enjoy

Swiss_Cheese

The Filament Whisperer

title here

Thanks.

I'm not on a machine with the slicer right now so I could not easily check.

your welcome

The Filament Whisperer

Please get rid of this!!!!!!!!

Okay thanks, I found the sequential option but when I try it, it says my model is too tall to do it.

NBD, this is just a one off, I mean I'm not gonna mass produce them and like sell them on the streetcorner.

Onesie-twosie should work fine for the rest of this project.

title here

I just realized how tricky that one may be.

Not only does it have a small footprint and a back and forth diagonal overhang, it has a hole in the footprint, reducing the contact area with the plate. Any 'pull' at all on the upper part of the print may break it away from the plate.

How tall is that model? There may be quite a bit of leverage toward the top for the pull of even the normal lay-down of the next layer to break it off the plate.

RE: Does layout alignment matter?

[...] Anyway, kind of unusual, 2-up prints fine all the time, 4-up, same piece, just the 2-up pattern laid twice side by side.

Did you happen to notice the print order? If the 2-up print front-to-back and the 4-up fail on side-to-side, that might be a hint as to why there's a consistent difference. You should be able to print those 4-up of course, but I too have gone with "fewer but safer" prints. I'd be curious to see if 4 worked if you lined them up like the 2 prints are. If that helps, which direction works? The printer is slinging a heavy bed around on Y, so front-to-back would be where I'd expect problems.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

@annier

If you post a .3mf with the model in it I can set it up for you pretty quickly and you can use it for an example.

Regards

Swiss_Cheese

The Filament Whisperer

Sequential printing gantry height workaround (sometimes)

Okay thanks, I found the sequential option but when I try it, it says my model is too tall to do it.

Just in case somebody else encounters this: Someone (I can't recall who) noticed that you can print sequentially at heights higher than the gantry height if you:

- Set the gantry height setting @Ringarn67 highlighted to a higher value.

- Ensure that all taller prints are only set up across on the Y axis.

If all your other settings are correct, you can print get away with taller prints than with the normal sequential printing layout.

NBD, this is just a one off, I mean I'm not gonna mass produce them and like sell them on the streetcorner.

Onesie-twosie should work fine for the rest of this project.

I'm sure this is overkill for this specific print. I have had cases where sequential helped a lot with stringing with some filament's so wanted to highlight a solution for anybody else that runs into this.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Get rid of this stupid thing!!!!!!!!!

Okay, let's see if I can cover everything here...

The main belt links are 35mm tall, to fit a more or less standard jeans belt loop.

The project is almost finished, just a few more links to go. I did quite a few of them yesterday afternoon and evening, just had to remember to go back in the kitchen every top of the hour and remove-wipe-press the button again. 2 up is always perfect.

Now, not to sound unappreciative of the offers for help but I really don't feel like effing around uploading models and such for something I'll never print again. I mean, a 4 up print takes over an hour to fail and that's an hour I will never get back!

I really think that I'm running up against some of the limits of what this thing can do, and since I care far more about the finished product than the process, I'm just gonna move on to the buckle and then to other projects.

Now the buckle may be another challenge! I know it will need supports and I'll certainly end up picking them out with tweezers!

Thanks again gang!

title here

Here's another question and possible suggestion.

Did you ever try it (n-up) using a brim instead of the skirt? That will give an object with a small footprint a lot more holding power. The brims normally break away cleanly.

If your model is 35mm tall, and with a very small footprint with a hole in it, I can really envision about anything that pushes the top of the model, even slightly, being able to rip it loose from the plate.

Get rid of this!!!!

Here's another question and possible suggestion.

Did you ever try it (n-up) using a brim instead of the skirt? That will give an object with a small footprint a lot more holding power. The brims normally break away cleanly.

If your model is 35mm tall, and with a very small footprint with a hole in it, I can really envision about anything that pushes the top of the model, even slightly, being able to rip it loose from the plate.

Well, uh, no I didn't. Why? Well {blush} I just didn't think of it. 🙂

See'n as how it's all printed now, I guess I won't be going back and trying that, but I will file that away as something to try if I do something like this again.

Thanks

Brims

I’ve printed caribiner parts with similar limited contact with build plate. The brim definitely is the way to go.

brim

I’ve printed caribiner parts with similar limited contact with build plate. The brim definitely is the way to go.

I have a couple of difficult to keep stuck prints and a brim certainly helps. It prevents the print from dislodging and or warping.

--------------------

Chuck H

3D Printer Review Blog