RE: life adjust Z - my way

➡ update (14.01.2018): calibration surfaces for PLA, ABS & PETG (generated with the latest S3D version, lin-advance, G87 and preheat procedure to avoid nozzle dripping (tnx 2 PJR)):

Attachment removed

Is this using linear advance 1.5?

RE: life adjust Z - my way

The commands to enable Linear Advance are embedded in the Life Adjust gcode: M900 K30 for PLA and K45 for PETG. I believe the version in use is pre-1.5 using ranges from 30-130 versus specifying a mm/mm/s value of 0.1-2.0mm.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: life adjust Z - my way

Hello calibration gurus,

I have some interesting results to report from my calibration series.

Using the supplied PLA on a MK3 that needed recalibration after i stuffed up.

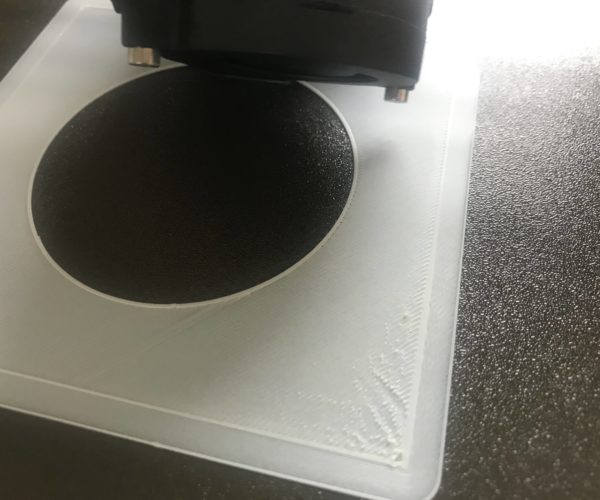

Printing v6.1 of Jeff's square on the textured sheet.

-1.600: basically single strands with no adherence to each other

-1.650: same thing with only marginal adherence towards the corner

-1.700: still easily separable strands

-1.750: good adherence between strands but surface somewhat rough

-1.800: good adherence but surface almost like sandpaper

so last attempt at 1.725 and back to easy breaks between some lines, especially towards the centre

Based on that rather frustrating series my question. Is the calibration so sensitive that I have to try to find the sweet spot between -1.725 and -1.750?

Thanks in advance for your thoughts.

Hansjoerg

RE: life adjust Z - my way

[...] Is calibration so sensitive that I have to try to find the sweet spot between -1.725 and -1.750?

Not usually in my experience. I find that there's a range of +/- 0.06 in which the results look good. It may vary by filament or other factors somewhat. Be sure the print surface is very clean. Also, a textured sheet may cause the square to look rough at the proper height. A picture would be helpful!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: life adjust Z - my way

Hello calibration gurus,

I have some interesting results to report from my calibration series.

Using the supplied PLA on a MK3 that needed recalibration after i stuffed up.

Printing v6.1 of Jeff's square on the textured sheet.

-1.600: basically single strands with no adherence to each other

-1.650: same thing with only marginal adherence towards the corner

-1.700: still easily separable strands

-1.750: good adherence between strands but surface somewhat rough

-1.800: good adherence but surface almost like sandpaperso last attempt at 1.725 and back to easy breaks between some lines, especially towards the centre

Based on that rather frustrating series my question. Is the calibration so sensitive that I have to try to find the sweet spot between -1.725 and -1.750?

Thanks in advance for your thoughts.

Hansjoerg

I would think the textured sheet would cause problems with the normal calibration squares. The surface variation in the texture is a significant portion of a single layer's depth. In order to get adhesion in the low points, live Z has to be set as though that were the height of the build plate for the entire surface. As you move over higher areas of the texture, the print head is way too close and you get filament pushed up around the side of the nozzle making little ridges, so the surface feels like sandpaper. Based on your numbers, I'd go with -1.750. You have to have good adherence between the individual extrusions. Also check the points where infill meets the perimeter for "pin holes". If there aren't any, or just a very few, then stay with -1.750. If there are lots or they are big, then you need to go towards -1.800, even though the surface may get rougher.

Try printing two layer squares and see how the two side look.

RE: life adjust Z - my way

Thanks guys, much appreciated!

The textured sheet was such an obvious thing that it definitely needed to be pointed out by other people (hand->forehead).

That aside, what I haven't really understood yet, should you actually be able to feel ripples when you move a finger nail perpendicular to the strands or should PLA feel completely smooth? Apologies for the stupid question...

Cheers

Hansjoerg

RE: life adjust Z - my way

if the surface is individual strands when you peel it off, your extruder is too high,

if the surface peels off as a single sheet it's just about right whether it is smooth or slightly rough

if the top surface of the first layer, is rough, and the underside is rippled, the extruder is too low!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: life adjust Z - my way

@joantabb

brilliant thanks, that was exactly the level of simplification that I needed!

RE: life adjust Z - my way

Are you using 7x7 mesh bed levelling?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: life adjust Z - my way

Sorry Joan, you lost me there, I just let the printer check it's 9 reference points...

Hansjoerg

RE: life adjust Z - my way

Hansjoerg,

if you go to the LCD configuration menu, and select Mesh Bed levelling, you should find an option to change to 7X7 mesh bed levelling,

this forces 49 rapid tests, and greater granularity to the mesh bed levelling...

this will help you get better results

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: life adjust Z - my way

That is, if you've updated your firmware 😀

RE: life adjust Z - my way

I am having issues with the print sticking to the bed and curling on the first layer, also it will have issues after a few layers and start going everywhere. I tried using this gcode to print the 75x75mm square and it printed out very nicely; however, when I take it off the bed it is made up of individual strings and falls apart and no way can I even print the z level on it. lol

Does this mean it isn't being squished enough so the nozzle needs to be lower? I currently have it at .370mm. Does that number need to go up or down?

Thanks

RE: life adjust Z - my way

@maincityimp

if you have individual spaghetti strings you are too high, increase the negative live z number

you can adjust whilst the print is running,

watch what happens.

the print surface should start to go smoother, then if it starts to ripple, or go rough, you have gone too far!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: life adjust Z - my way

@joantabb

That was helpful. Thank you, Joan! 😊

RE: life adjust Z - my way

Glad to help!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: life adjust Z - my way

I'm new to 3d printing, I had a print come out a little rough. Found this thread. I did you live adjust and was able to get a smooth finish but only 1 mm thick. Not sure what I need to do. TIA

RE: life adjust Z - my way

@14sheudo

can you provide pictures of your problem prints?

and the settings used for the print?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: life adjust Z - my way

I am referring pretty much everyone that has first layer problems to this thread.

I am hoping that if you have problems you will read this thread - then open your own thread for your specific problem if you need to.

Don't turn this one into more of a book than it already is.

(hint to moderator - it would be OK with me if you made this one read-only, except for the author)