Re: life adjust Z - my way

Thanks Bob I will do so after this print is done and see if it locks things down I would not have thought of that one. good detective work on figuring it out.

Re: life adjust Z - my way

Let us know if that fixes your problem. It would be good to have a definitive confirmation!

Thanks Bob I will do so after this print is done and see if it locks things down I would not have thought of that one. good detective work on figuring it out.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: life adjust Z - my way

Thanks for your efforts. This thread has helped me immensely.

--------------------

Chuck H

3D Printer Review Blog

Re: life adjust Z - my way

<r><QUOTE author="bobstro" post_id="119883" time="1544635337" user_id="51417"><s></s>

</e></QUOTE>

<QUOTE author="randolph.l" post_id="119880" time="1544633179" user_id="85468"><s></s>

</e></QUOTE>This may have been mentioned before, but someone posted that running the on-board Live-Z adjustment to completion is required at least once to set a flag to avoid drift between power cycles. I make a point of doing so any time I upgrade firmware, so haven't had the issue, but drifting Live-Z seems to happen. This will hopefully help.

[...] any thoughts on what is going on here?

<e>

<e>

Please explain what “on-board Live-Z adjustment to completion ” is. Is this running the build in Z Calibration from the LCD menu.</r>

Re: life adjust Z - my way

Yes.

[...] Please explain what “on-board Live-Z adjustment to completion ” is. Is this running the build in Z Calibration from the LCD menu.</r>

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: life adjust Z - my way

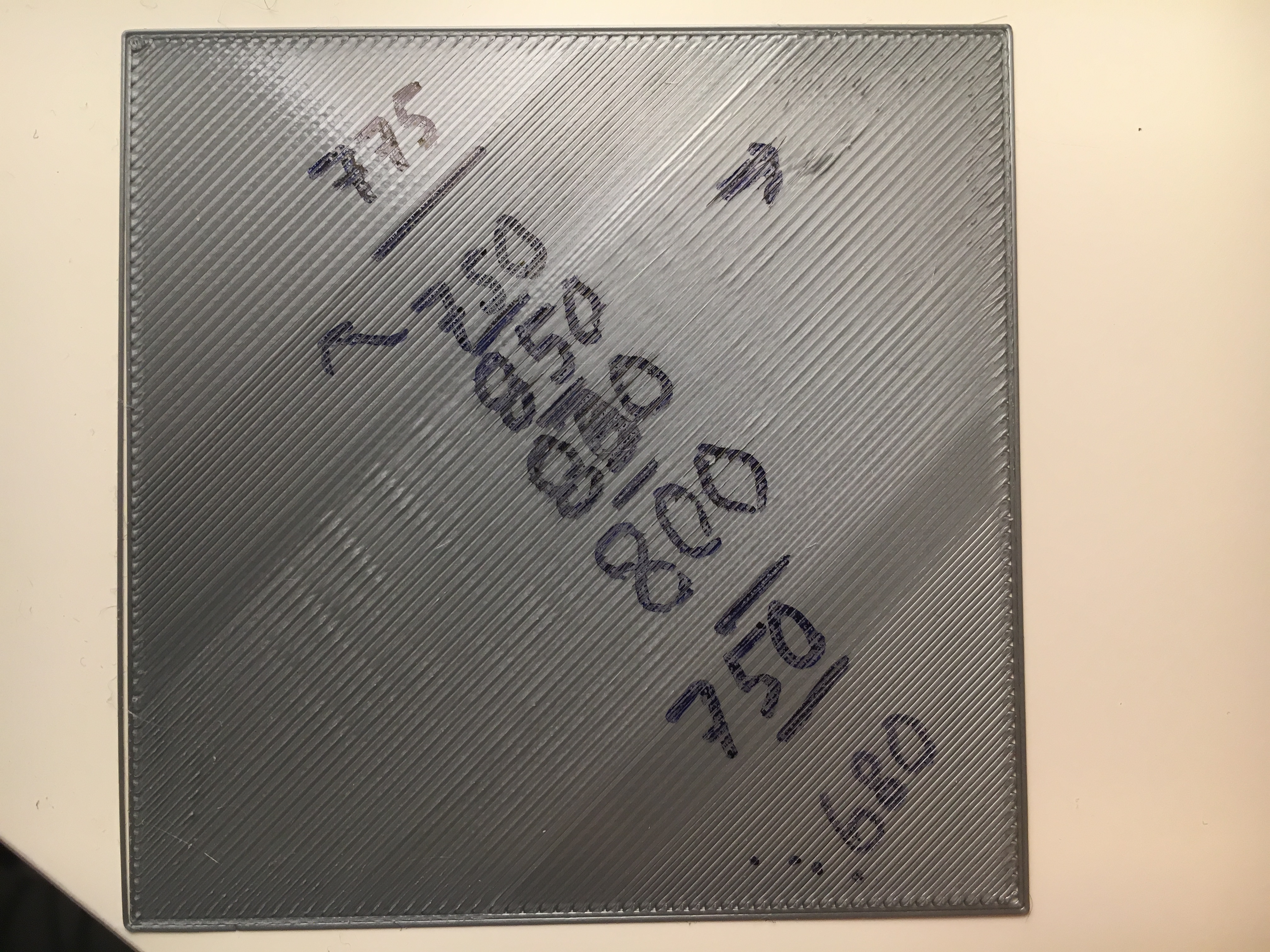

I had huge problems with bad adhesion, even after the Wizard first layer correction had run with what I thought was satisfactory results. Here you can see my calibration process in one single go. That in addition to dishwasher liquid and sponge cleaning made all the difference.

680 stuck terribly bad. 750 had slight gaps. 850 had hairs and blobs sticking out. 775 was the sweet spot.

Thank you for the gcode and advice! 😀

Re: life adjust Z - my way

Bump to put this back on the first page. perhaps it should be pinned?

Re: life adjust Z - my way

ya, gotta keep this page around.

it's all about the Z baby!

I have a Prusa,therefore I research.

Re: life adjust Z - my way

What is meant when people are saying -500um, etc. I’m not too familiar with this and I have my current Z set at -1.130

Thanks!

Re: life adjust Z - my way

What is meant when people are saying -500um, etc. I’m not too familiar with this and I have my current Z set at -1.130

-500 micrometers (um) is -0.500 mm

your Z is -1.130 mm or -1130 um

Re: life adjust Z - my way

Had to factory reset so now I'm having to adjust my Z. This thread is FAR better than the test the printer itself does. Thank you.

Am I correct that the height of this print should be .2mm when it is perfect? Even if a lower Z value produces a better looking result?

For example a 0.750 setting looks like it has me at .22mm for the thickness while a 0.800 setting is .3mm, but has a better finish.

Just want to make sure I understand all this correctly.

Re: life adjust Z - my way

Had to factory reset so now I'm having to adjust my Z. This thread is FAR better than the test the printer itself does. Thank you.

Am I correct that the height of this print should be .2mm when it is perfect? Even if a lower Z value produces a better looking result?

For example a 0.750 setting looks like it has me at .22mm for the thickness while a 0.800 setting is .3mm, but has a better finish.

Just want to make sure I understand all this correctly.

That's my understanding. You could be over extruding slightly.

Re: life adjust Z - my way

Hi all,

thanks for your help.

I am a super newbie owner of MK3 kit.

I am trying to do this fine adjustment, but without success.

I run the PLA gcode attached from the SD card, it starts with the calibration and executes it successfully, then set the temperature at the designed level and then it shuts down without printing.

What am I missing?

Re: life adjust Z - my way

Also be careful if you have the textured PEI surface as you will get slightly thicker measuring prints due to the non flat surface, I typically get 0.23 to 0.25 with a good first layer, even though supposedly i am printing a 0.2 layer.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: life adjust Z - my way

bump to keep on first page.

Moderators how about sticking this thread so we don't have to bump it every few weeks

Re: life adjust Z - my way

I am using a 45 degree narrow plane in my live Z adjust as I do not care for waiting until I see the print.

Re: life adjust Z - my way

bump back to first page would a monitor please pin this thread?

Re: life adjust Z - my way

Randolph I agree but a new locked thread should be started with the procedure and the test files added plus a link this thread. This is way too long. And a non typo subject heading.

The same same for cleaning. These are the two threads which occur over and over.

Also as this thread has gone on for so many pages do moderators still visit ?

John

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: life adjust Z - my way

be patient ;-).

i generated the gcode with simplify3d's default settings for printers. they first heat up the print surface and when the bed temperature is reached, the nozzle starts to heat.

Is there anything special about adding the 7x7 Start Gcode to this set of gcode test files

S3D_calibration_surfaces_75x75@200um_v6.1.zip ?

Do I just open them each in a text editor search for:

G28 W ; home all without mesh bed level

G80

and then change those lines to

G28 W ; home all without mesh bed level

G80 N7 ; mesh bed leveling 7x7

just checking before I do something dumb.

or would I be better off looking for your STL file somewhere in the 48 pages of this post and slicing it with the Prety PETG settings from CW on the facebook community forum, with the slic3r Alpha5

Re: life adjust Z - my way

Thanks for this file, it solved a problem that just cropped up.

I cleaned the print beds with acetone because prints were curling up. Probably from removing prior prints too soon before they were fully released.

I used your file and got a great result from my new z setting.

I have to admit I panicked a bit when I was watching the screen and it set the temp for the extruder to 170. I immediately tuned to 225 and let it print and it worked.

I then checked your gcode and saw that you had it move up to 225 before starting the calibration print.

Just curious, why do you have it go to 170 first?