Issues with Trapezoidal Nut

Hi,

Putting my 3rd Prusa i3 together, so I have some experience behind me for starters 🙂

The issue is that already when assembling I noticed that the other trapezoidal nut was a tight fit. It does go into place by rotating, but needs some twisting force whereas the other just pretty much rotates freely and without any effort.

When I run the setup wizard I get all correct from the first part, but when trying the next step in the calibration I get almost immediately an error when the Z-axis starts moving: "Calibration failed! Check the axes and run again."

I assume this is because the other one moves a little, other not so much so it somehow assumes the rod/axis is stuck and fails.

The question is: is there any way to fix the trapezoidal nut or do I just need a replacement? I tried a little bit of grease and viling with no noticeable difference. It does move a little bit more smooth, but apparently not enough.

Or am I facing some other issue?

Thanks for the advice.

Re: Issues with Trapezoidal Nut

Here's a short video of both working and not working.

Faulty first:

And the proper one:

I also tried switching the nuts between rods and the effect is the same. Rods seem to be fine.

Oh, and the music is Toto 🙂

Re: Issues with Trapezoidal Nut

I am having the same issue.

Re: Issues with Trapezoidal Nut

If you don't see any debris in it, I would contact support via chat and get a new one coming.

Re: Issues with Trapezoidal Nut

I had the same issue. Nuts were very free when I took them off the rods but after sitting on my bench for about an hour before I tried threading them back on they shrunk. I think I swapped the sides, put the left one back on the right side and vice versa and also built it in my garage which was very warm and humid. One of those 2 factors made it almost impossible to rethread them. I am certain I did not cross thread them but it took a lot of force to spin them down the rod. I swapped sides but it made no difference.

After dreading not being able to finish assembly of my printer until support could ship me another set, I finally found a tip out on the web (thank you unknown author) that worked perfectly. I threaded each nut down about a quarter of the rod then used a lighter to heat up the top 3-4 inches of the threaded rod. Once it was nice and toasty, I threaded the nuts back up to the hot end and down a few times and they instantly loosened up to where I could give them a flick and the would spin a few threads on their own. They have worked fine ever since. Hope this helps.

Re: Issues with Trapezoidal Nut

💡 I come at this hobby from a background in mechanical design and as a manual machinist and I just wonder at the decision to use even an engineered plastic lead screw nut on a metal lead screw... it is just asking for problems the desired inexpensive nut would be of the Oilite sintered bronze type https://oilite.com/Our-Products and if you are shipping 6,000+ MK3 printers a month having a pair of these made for you on automatic screw machines or CNC production would add very little to your production costs on each machine... set that cost against the tech support and replacements mailed to builders and you might even come out ahead. 💡

Just one mans opinion.

Re: Issues with Trapezoidal Nut

Just one mans opinion.

Don't hold your breath expecting PR will read your post, much less act on it. 😉 The consensus seems to be that they don't read their own forum--it seems to be for those of us on our own out here in the wilderness... 😐

Some of their design/business decisions have truly mystified me (and continue to do so).

I think (and I'm just guessing) that part of the decision to go with Delrin nuts (aside from cost) may have been to reduce noise. I don't know if it was worth it. It sounds from your background like you'd know better than I on that point.

That said, problems with these nuts seem to be common (from the number of issues/threads/posts about them).

I got 2 that were so stiff I had to crank on them to even get them on the threaded rods. I thought moving them up & down the length of the rods might loosen them up or shake loose any burrs/debris. Silly me. 😳

(It would also be cheaper for them to just include a couple extras--at least for those of us on the far side of the pond...)

[RANT]

Two of the printed parts I got were also broken. I notified CS, who said the replacement nuts & parts would be shipped. They were--finally--8 days later (evidenced by their email and the notice from DHL on when they were picked up) while my half-assembled kit sat on the kitchen table...

[/RANT]

I hadn't heard about the heating up of the threaded rod fix, but I'm not sure I would have tried it myself. With my ineptitude, I might have melted the durn things into the threads and really s****ed myself...

That's "MISTER Old Fart" to you!

Re: Issues with Trapezoidal Nut

First let me apologize for replying in this thread rather than starting something in the https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f40/ section but I did not see a general chat section even in that section so mods please move this where it belongs

and as one old fart to another Rufus, the low level of company participation is something of a norm in 3D printer manufacturing They like to have their support concentrated in their online chat systems eMail contact, and even phone call systems that way they can control the interaction and not have threads barged into with a lot of other users kibitzing (Frequently in a less than genteel way) and turning a support thread into a flame war.

I am at the waiting for shipped notice (should be in the next few days I am told by customer support) to show in my email; so I am studying the documentation of the build process in the online manual as I take notes and read all feedback on each step and annotate a printed copy of the build online manual... I am very detail oriented and I make notes where I see that I have tools that might be easer to use than the inexpensive metric hex wrench set do needle nose pliers and do Phillips screwdriver* and selecting what I might find useful largely based o the comments on each step.

For example I have seen comments in a few places where some of the printed parts lacked squareness or were defective for some users with things like layer separation when screwed down too hard(and if they are cranking out 6000 printers a month and assuming that about 5% to 10% of folks with defective parts actually post on the forums or manual comments that is still a very small number of kits with this sort of problem) and I can check for things like that at my metrology bench on the surface plate... if needed I can either 3D print on my SeeMeCNC Rostock MAX V2.5 delta printer or even make a replacement out of aluminum 6061 -T6 in my home machine shop. (I am retired and keep up my shop skills making working scale model live steam stationary engines... I also plan on using my micro inch pound torque driver to be sure to avoid over stressing the provided printed parts and refer to either machineries handbook for some starting figures. I have more than a few machined replacement parts on my delta (hot end fan shrouds for example I silver soldered out of shaped brass sheet in one case.

this Prusa will be my first Mendel type printer. this is a hobby for me and I intend to use it to make the parts I need to update my Rostock to version 3.2 with a few bells and whistles and then next on the hit trade is building a MPCNC (mostly Printed CNC router table) after that a RailCore II

(What is the RailCore2?

RailCoreII is a CoreXY 3d printer designed and created by J. Steve White & Tony Akens. It was conceived via a discussion between us on the #reprap IRC in 2017. The primary considerations were to build a CoreXY with an enclosure integrated into the frames itself, use linear rails for all motion contraints, and make it as customizeable as possible. Once we built ours, we decided to release the design under an open source license.

The thingiverse link for all printable models is here:

Standard Parts: https://www.thingiverse.com/thing:2407174

Optional ZL Parts: https://www.thingiverse.com/thing:2765693 )

So my hobby calendar is just about full uo for the next year or two but in my 70s I am a firm believer in the use it or loose approach to aging and all these things help to keep my mind and body from ossifying (I hope 😉 )

* (another one of my pet peeves in the area of industrial design is the use of the designed to fail Phillips head fasteners by anybody any where... there are so many better screw head designs but that is a rant for another time and another place

Re: Issues with Trapezoidal Nut

if needed I can either 3D print on my SeeMeCNC Rostock MAX V2.5 delta printer or even make a replacement out of aluminum 6061 -T6 in my home machine shop.

That's great. (Seriously) I envy you that. My own life experience is quite different.

When I contacted CS about my broken printed parts, they suggested I print my own.

[Pregnant Pause.....]

On what? This is my first 3D printer, and I'm the first kid on my block (so to speak) to get/have one. (IOW, I don't know anyone else with one.) Given all the marketing they do to attract first-timers, I thought it was kinda presumptive.

That's "MISTER Old Fart" to you!

Re: Issues with Trapezoidal Nut

On what? This is my first 3D printer, and I'm the first kid on my block (so to speak) to get/have one. (IOW, I don't know anyone else with one.) Given all the marketing they do to attract first-timers, I thought it was kinda presumptive.

I think there is a perception in some of these companies (because they are so close to the whole world of maker spaces and such) That everyone has access to that kind of local support... When I built my delta I was in exactly the same relationship to the world of 3D printing as you were when you started I was lucky that I have a strong mechanical background I would not recommend a Delta as a first printer but I have love of odd mechanical motion systems.

Where I live in Rural Maine I don't have any other 3D printer users within about 50 miles (well the local high school has a few but it is in an academic design and build program and not ope to outsiders... In fact I made a few aluminum and steel parts for them for their printers.

But that is why these forum structures can be so helpful not just to folks new to the hobby but also to folks like me who are embarking on the exploration of alternate motion systems to what they are used to.

Re: Issues with Trapezoidal Nut

Late to this subject, but Delrin has been used for quite a while in mechanical settings due to strength to weight and self-lubricating properties. I don't see a problem with it for the X-Axis, but a warning needs to be made a dab of grease can ruin the part. Even a synthetic PTFE grease I inadvertently applied to the screws while installing new bearings has caused damage. And I KNEW the screws were self lubricating.... that's the part that really hurts.

And, trying to find replacements is a joke. I got some brass nuts off Amazon that claimed to fit: they didn't. So far, the only other options I've found are on Ali-Express: so I can order something from China that probably won't work. If anyone has a source for the "right" parts, please speak up. And no, Prusa doesn't have them to sell.

ps: I did find a set on Amazon that look like the real thing; but the $28 price seems well into scab territory:

https://www.amazon.com/WillBest-Prusa-Printer-Trapezoidal-Reprap/dp/B07FMLHYWH

Re: Issues with Trapezoidal Nut

Hello,

I'm also having issues with the Trapezoidal Nuts, can someone direct me to the proper link to contact Customer Service? i've tried 'contacting them' through their main page, but i've received 0 replies from them. I really just want to put this thing together already! 😥

Re: Issues with Trapezoidal Nut

a warning needs to be made a dab of grease can ruin the part. Even a synthetic PTFE grease I inadvertently applied to the screws while installing new bearings has caused damage.

Can you elaborate on how this happens? Sounds like I might need to bust out the IPA since there's almost certainly some grease on my Z rods from assembly and handling...

Re: Issues with Trapezoidal Nut

Hello,

I'm also having issues with the Trapezoidal Nuts, can someone direct me to the proper link to contact Customer Service? i've tried 'contacting them' through their main page, but i've received 0 replies from them. I really just want to put this thing together already! 😥

Login into the estore and you will find the CHAT session box down in the right hand corner.

Re: Issues with Trapezoidal Nut

sewing machine oil (cant speak to all lubricant formulations but a delrin data sheet should cover the basics) will not damage the delrin nuts but it is not needed as they are self lubricating

Re: Issues with Trapezoidal Nut

a warning needs to be made a dab of grease can ruin the part. Even a synthetic PTFE grease I inadvertently applied to the screws while installing new bearings has caused damage.

Can you elaborate on how this happens? Sounds like I might need to bust out the IPA since there's almost certainly some grease on my Z rods from assembly and handling...

When I replaced my rod bearings, I packed them with SuperLube Synthetic; and while I was at it I squeezed out s dab of grease on the screws. A week later I started seeing black residue on the screws. I removed the grease best I could... but it is really hard to get it all off. In the months before the grease, I never saw any hint of TZ nut wear on the screws.

I still haven't found replacements. And Chat just got me a "They are not available for purchase by themselves." Seems they come with motors attached. Ouch. Never did find any true replacement parts besides the $27 a pair scab pricing.

Re: Issues with Trapezoidal Nut

a warning needs to be made a dab of grease can ruin the part. Even a synthetic PTFE grease I inadvertently applied to the screws while installing new bearings has caused damage.

Can you elaborate on how this happens? Sounds like I might need to bust out the IPA since there's almost certainly some grease on my Z rods from assembly and handling...

When I replaced my rod bearings, I packed them with SuperLube Synthetic; and while I was at it I squeezed out s dab of grease on the screws. A week later I started seeing black residue on the screws. I removed the grease best I could... but it is really hard to get it all off. In the months before the grease, I never saw any hint of TZ nut wear on the screws.

I still haven't found replacements. And Chat just got me a "They are not available for purchase by themselves." Seems they come with motors attached. Ouch. Never did find any true replacement parts besides the $27 a pair scab pricing.

errrmmm

https://shop.prusa3d.com/en/mk3-and-mk3s-printer-parts/682-trapezoid-nut-lead-nut.html

Re: Issues with Trapezoidal Nut

errrmmm

https://shop.prusa3d.com/en/mk3-and-mk3s-printer-parts/682-trapezoid-nut-lead-nut.html

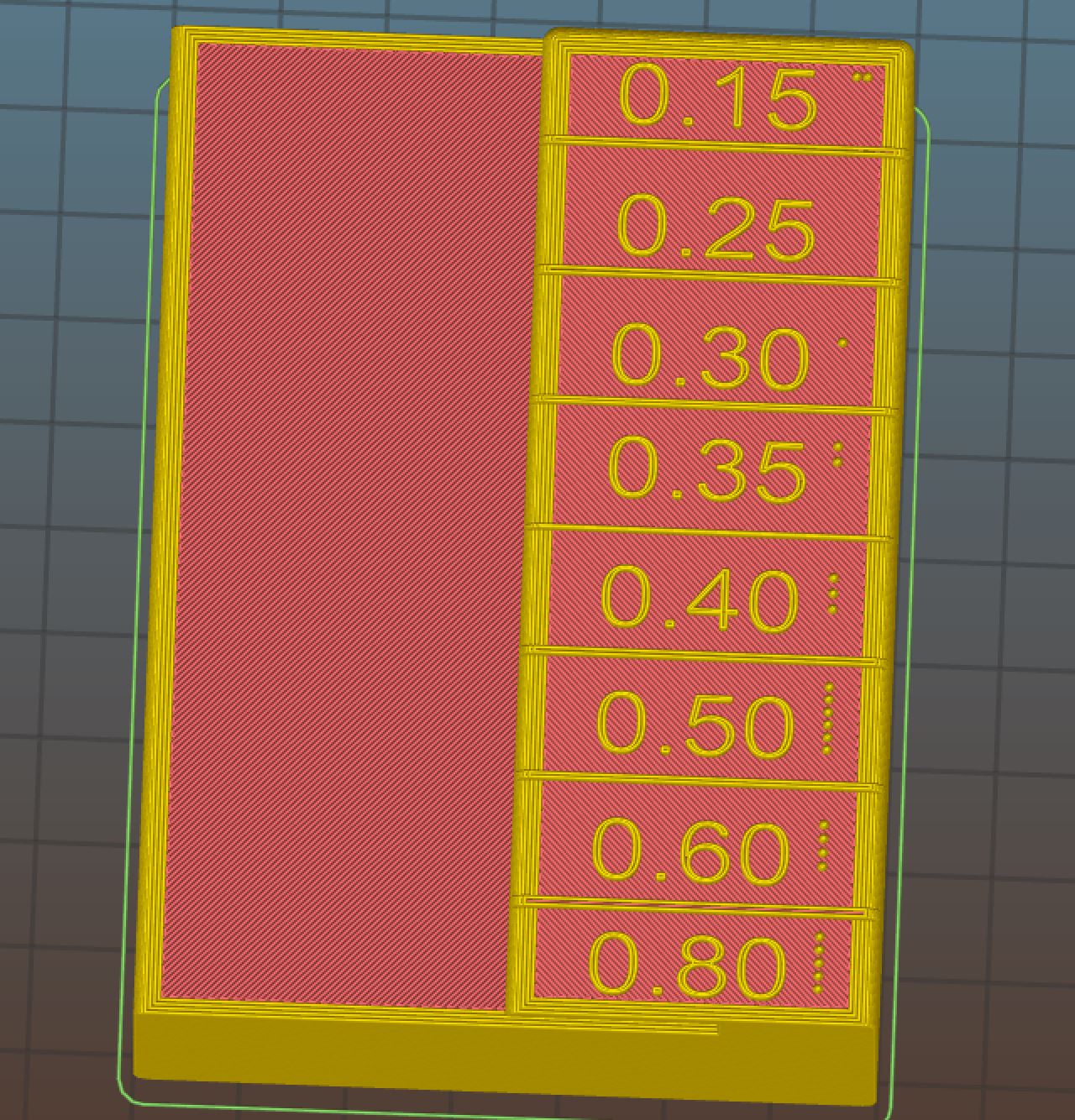

Good they finally fixed it (sort of - see image). They were NOT available for order a few months ago. Back then, CHAT guy told me if I had an order in place, they could "hand add" a couple" for free, but wouldn't sell me the nuts by themselves.

$6.50 each is a bit spendy, but still fair if you need them. But I was trying to buy 4 so that the $14.00 shipping would be reasonable... These nuts must be as hard to make as the PEI Powder Coated sheets.

RE: Issues with Trapezoidal Nut

@ossi-t

I know this is an older post, but it is exactly 100% match to my printers problem. Was the solution to replace the Trapezoidal Nut? I read through the post here and did not see your solution. Thanks!

RE: Issues with Trapezoidal Nut

@rusty-m3

Hows it working now, I have same problem, heated rod like you said threaded it up and down a few times and it becomes to were I can spin it with a flick but when it cools or after a couple minutes its almost the same