intermittent X axis crash

Hi everyone,

I got my kit and assembled everything. Ran all the tests fine and did a couple of the prusa files off of the SD card, which printed fine.

When I started to print one of my 3d sculpts, it started fine and went for a couple hours. Then it crashed to the right side of the X axis. When I clicked to resume printing, the printer seemed to think the print was shifted 4 inches to the right. It started printing in the air and then crashed against the right hand side again.

I recalibrated the machine with the wizard and re-calculated my model through prusa control in case there was a problem with the G code. I then was able to print the model, which took 13 hours, with no mishap.

I wanted to print the same model larger, so I changed the angle of the object on the bed and made it larger. Then I calculated the Gcode again. The same error happened again. Everything was going well, but after about 2 hours the printer seemed to get confused about the X axis and the head crashed against the right side again. Any thoughts?

Thanks!

Re: intermittent X axis crash

You might check the belt isn't slipping over the gear on the X-Axis motor, and that the gear is properly attached to the motor shaft. Also, any chance you are printing from a computer rather than SD card?

One set screw MUST be set on the flat of the motor shaft. Tighten it down first. Then tighten the second counter screw to lock the gear in place.

By the way, you don't need to recalibrate everything after a crash, the printer will rehome when you start a new print.

Re: intermittent X axis crash

Thanks for the reply.

I don't see any indication of the belt slipping. The gear is tightened properly with the screw against the flat part of the shaft. Also, I'm printing from the SD card.

Before I saw your reply I did what I did the last time this happened. I went through the calibration wizard and redid the Gcode in Prusa control before trying the file again. During the calibration process, there was a point where the LCD screen just showed garbled text. I hit the reset button, and when it reset it continued the wizard from where I had left off, so I completed the process. I set it to print overnight and when I got up this morning there had been another crash on the X axis.

In both times this happened, there was no layer drift or anything in the print. It prints accurately up to a certain point and then just veers off to the right hand side. And after the print is stopped, it still thinks the center of the plate is a few inches to the right. If I do a calibration test, it causes a crash on the right hand side.

Should I try reinstalling the firmware?

Re: intermittent X axis crash

Smells like https://github.com/prusa3d/Prusa-Firmware/issues/1522

If you have a Mk3, try turning off the filament sensor before the print, it is reportedly the cause of that "heating" issue, but at this time it's unclear whether that is related to the X/Y wandering off or not as there are other reports of the "heating" pause without print failure.

Re: intermittent X axis crash

I think the filament sensor was off--when I went to turn it off it said off. But I'll make sure it's off and try again. Thanks for the tip!

Re: intermittent X axis crash

If you have a Mk3, and not a Mk3S, definitely turn OFF the filament sensor. There are definite bugs in how it works - so many Prusa finally redesigned the printer to use a different style... though there are a few early reports of bugs with the new sensor design, too.

That said, a few people have no issues with the optical filament sensor on the Mk3.

I've seen garbled text with FW 3.5.1 after a false filament out detection ... when it happened to me I started having odd problems. Bed level was never right, prints were "off" and quality dropped. I eventually reset the printer using the Clear All steps, went through the full recalibration and got the full functionality back. But it sounds like you've done this, too.

Sometimes it can help to have a look at a model. Can you post an image of the failed print or the .STL (place the stl in a ZIP folder to upload).

Re: intermittent X axis crash

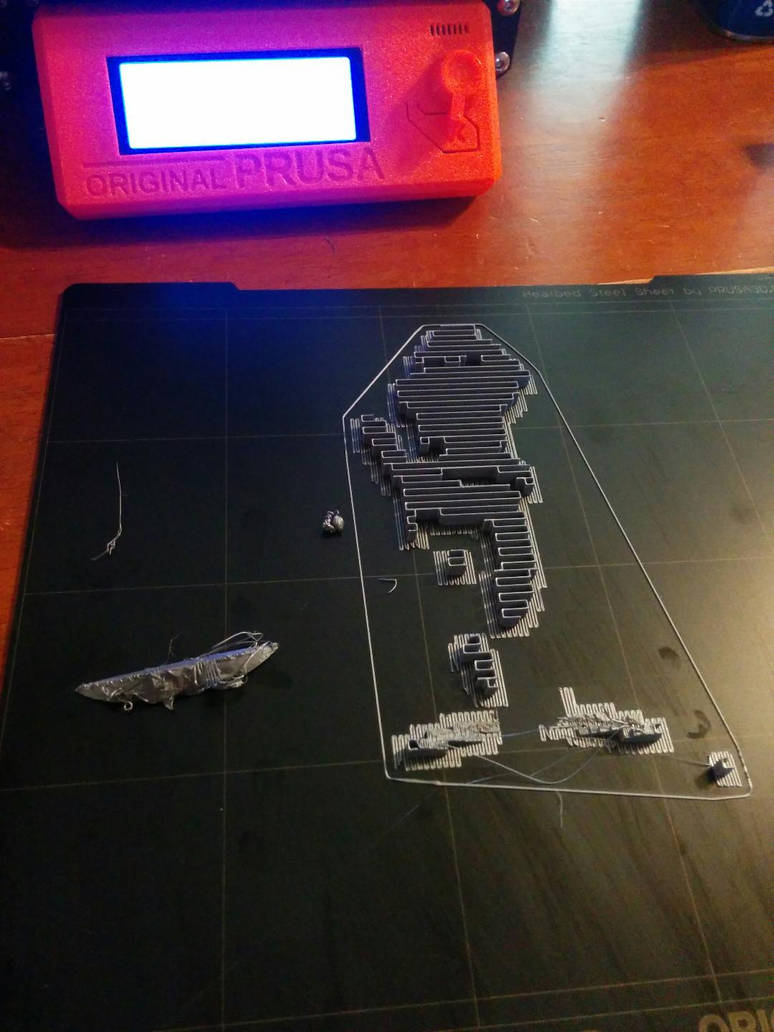

Here is an image of the first two times I tried the print:

The disc on the left looks fine. I don't see any problems with the printing--the printer just stopped at some point and crashed into the right side of the X axis. I went through the complete setup process again and redid the G code, then did the second print (on the right). It has some problems (I think the gashes on the chest are places where the support6s were touching and transitioned badly) but I'm pretty pleased with how it turned out. The only difference in the two files was that the second was set for 10% infill rather than the default 20%.

This is one where I tilted the model on its back so that I could try to print it at a larger size in the build volume. It was printing supports and part of the base, when the extruder glommed on to the base, lifted it away from the supports, and then shifted to the right on the X axis and started printing in the air until I stopped it.

Re: intermittent X axis crash

Well, I doubt the model in the upright position really needs supports. It looks like it was designed with 45 degrees in mind. Laying the model down is a bad idea because it will bring all sorts of FDM limitations into play. Best to keep it upright and cut it at the mid point, belt, etc. And glue the two halves. It works better than you'd think.

I suggest you keep printing and assume the garbled crash a one off event. But for your own sanity, keep the filament sensor off.

More on low angles: when printing a part that has supported or unsupported low angles, like a body laying prone, edges down wind of the fan aren't cooled well and will curl unless you slow the print down, a lot. The curl will add until it can catch the nozzle and it can break the model loose from the support. Had it happen many times. Also, print quality suffers when printing over a support, or even just printing low angles. The printer just can't print overhangs as well and the underside surface will be distorted. Try printing a ball, and look where the quality seems to jump from rough to smooth. It is the transition where the overhang becomes well supported by the prior layer. Overhang test models will also show this FDM limitation.

Re: intermittent X axis crash

Thanks for the advice! I did cut the model into two halves so that I could print it vertically at a larger size. I tried a print yesterday and, again, I got a fail. I actually saw it happen because I went to get a drink and stopped by the printer on the way. Everything was going well, about 2 hours into the print, and then the nozzle somehow went behind the print, nudged it (it actually tilted the print off the bed for a second) and then the extruder shifted a few inches to the right and started printing in the air. Really disappointing.

I don't know what to do at this point other than to just try again. I made some more adjustments to my model to make a couple detail areas easier to print and I'm just running it again.

Re: intermittent X axis crash

Another fail. This was a slightly smaller version of the previous attempt. I've got a picture here of the two side by side. The fail happened at pretty much the same height despite the prints being different sizes. The one on the left was dislodged from the bed and then the extruder moved to the right side and printed in the air. The smaller one, at that point, started to be dragged around by the nozzle, which this time didn't move to the right side and kept printing in the center.

Another issue I have is the bottom of this print. Everything else I've printed on the bed is smooth with nice fill. The bottom of this model has really crappy coverage despite the geometry being flat:

Re: intermittent X axis crash

Looks like it's tilted a few degrees relative to the bed. Use the 'surface to bed' option in Slic3r and try again? That minimal bed contact is what is doing you in.

Re: intermittent X axis crash

Agree the slanted base is a death knell for any print. Also - the brim should really be sticking better than you are experiencing. You might go back and really wash the steel sheet with a few drops of decent detergent and really hot water; handling everything only by the edges, and using only fresh paper towels to wash and dry -- no hand towels, dish sponges, etc. And when installing the sheet, again, handle it by the edges because even one fingerprint will dislodge a print the size you are making.

@Vintage: where is that "Surface to Bed" option found in the UI? As far as I know Slic3r PE doesn't have the feature. A user must 'painfully' rotate the part fractions of a degree and reslice to check alignment. Or use the CUT method to trim an angled base.