Inclined nozzle - cause of problem? how to fix?

I (complete newbie) bought a used MK3S+ a few weeks ago and am finally getting around to really getting to know the hobby. In general I have problems to get good looking first layers, but I blame this and also some adhesion problems on the badly stored PLA (of course I know how to dry it and store it properly).

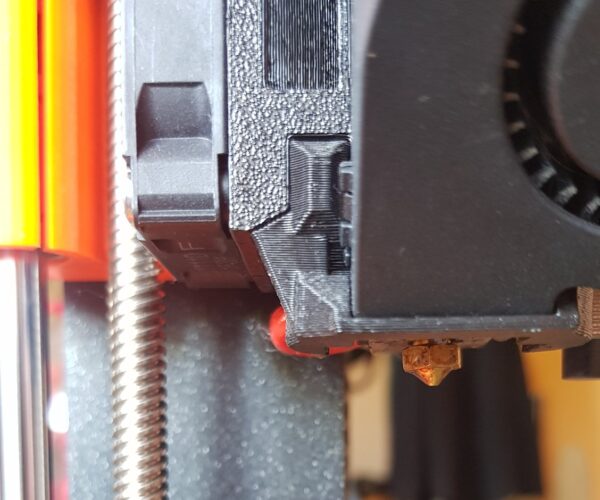

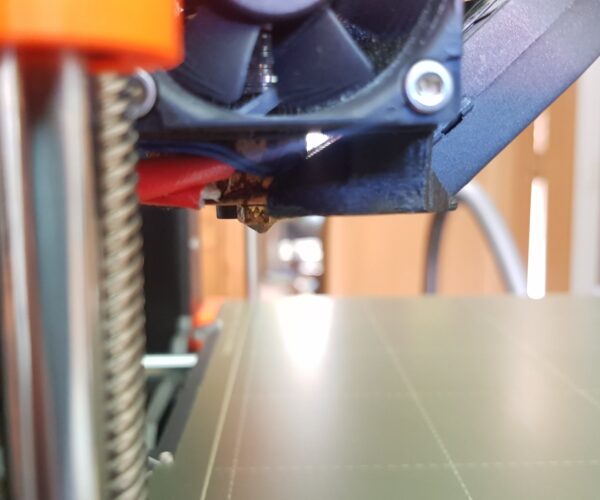

When printing the TempTower (PLA rainbow, 0.2mm, 0.4mm nozzle) I notice that the right rear corner (on the right in the picture) bends up in all temperatures. Only then did I take a closer look and notice that the nozzle or the entire hotend is hanging considerably crooked.

1. How can something like this happen?

2. can this lead to the problem described?

3. what can or must I do to straighten it out, or what would be better not to do under any circumstances? Is there a chance to avoid complete disassembling und changing the complete hotend?

Thanks to DeepL for translating...

Best Answer by jsw:

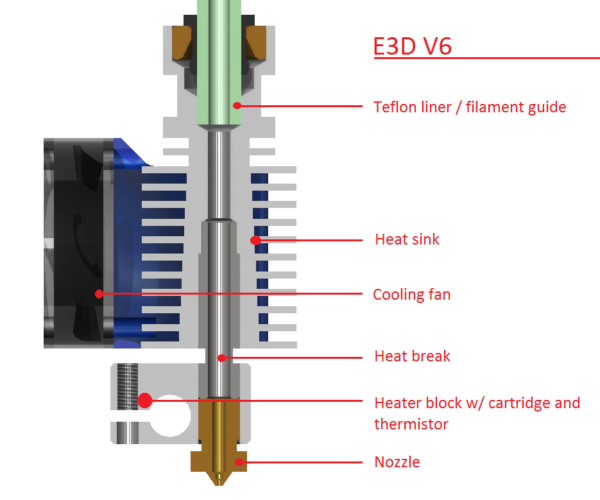

It appears to me that most likely your heat break (see illustration below) is bent.

If this were mine, I would disassemble the extruder, inspect it closely, and replace the heat break if needed. I would also give the whole machine a good once-over to check for any other damage as well.

You can get them from Prusa, or from Amazon in the States, or various other places.

RE:

It appears to me that most likely your heat break (see illustration below) is bent.

If this were mine, I would disassemble the extruder, inspect it closely, and replace the heat break if needed. I would also give the whole machine a good once-over to check for any other damage as well.

You can get them from Prusa, or from Amazon in the States, or various other places.

RE:

Thank you! Well, of course there is no other explanation than a bent heatbreak. It is possible that the previous owner tried to change the nozzle without securing the block against twisting.

I am also unsure because the block (in which the thermister is also clamped) can be twisted by a (very) few degrees without any force, as if the heatbreak is elastic or broken. That prevents me from trying to re-bending the heatpipe. On the other hand - what would I lose?

Presumably I have to try to remove the filament as completely as possible first? Heat up, unload the filament, loosen the transport screw and push it out with a suitable object (which one?)? I think Prusa also recommends doing this when changing to certain types of filament...

Changing the heabreak alone I did not find explained (yet). Any hints? sorry, got it.

I don't necessarily need to save every penny - would it perhaps make more sense to change the whole block straight away? Would https://www.3djake.de/e3d/prusa-v6-hotend the right choice? Should I consider another part if I am about to spend those bucks?

Or am I worrying too much and everything is much easier?

btw: I did a few other checks on the MK3S+ via menu, axis alignment and so on, and got fine results, so I think there are no other issues. Every thing sounds also absolutley fine to my technical ear. Z calibration is also done a few times without any problems.

RE: Inclined nozzle - cause of problem? how to fix?

I suggest that as a minimum, you buy

one new Heatbreak,

One new Thermistor and

One new heater

the Heatblock is optional, (depends how lucky you feel! 🙂

If you disassemble and reassemble carefully (Loosening the Nozzle, whilst the hot end is say 285C,

then you should have no issues reassembling the parts using just the heatbreak,

the thermistor wires are particularly fragile, and the heater wires are not far behind.

If you have them in stock, then there will be no further delay making the repair.

however, the heater and thermistor may be 'Glued' in, with old filament making them difficult to remove...

In which case, having a spare heat block, will allow you to use the new heater and thermistor with no delay

I generally keep heaters and thermistors in stock, as they can be damaged by Blobs of Doom!

which are a trauma most 3D printers, 'experience' quite early in their learning curve

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE:

Since the time to edit my post is over, here is an update: As I understand it, it is sufficient to unload the filament, loosen the (heated) nozzle and disassemble the hotend as described on the PRUSA help page. Also, I suspect that the heat break is partially broken and only held in place by the PTFE. So I'm going to order a replacement PTFE and heat break and try a repair. Edit: And well, I think I'll get a heater and a thermister as well.

And I'm not sure if the printer came to me like this or if I broke the heat break myself when checking a printed nozzle key 🙁 I probably underestimated how fragile a heat break is.

RE: Inclined nozzle - cause of problem? how to fix?

You need to be careful to hold the heater block steady when removing or changing a nozzle. Yes, you can damage the heat break by tweaking it.

The PTFE tube does not extend to the heat break. You may have simply bent it.

I would do a disassembly and inspection. If you order everything Joan cited, you should have everything on hand if you need it.

RE: Inclined nozzle - cause of problem? how to fix?

Maybe order a spare 0.4 mm brass nozzle while you’re at it. Cheap insurance!

RE: Inclined nozzle - cause of problem? how to fix?

Some time ago (during the darkest days of the pandemic) I created a 'crash kit' for the Prusa printer of items which I thought might be a bit difficult to acquire should I need them to keep the machine operating.

Among the items is a complete hot end. I figured that I could either use parts of it if needed, or if necessary, replace the whole thing in one shot. Fortunately it's still sitting there unused, but it's there if I need it.

RE: Inclined nozzle - cause of problem? how to fix?

Maybe order a spare 0.4 mm brass nozzle while you’re at it. Cheap insurance!

Got a bunch of spare parts with the printer, a heatsink included, and half a dozen nozzles. Maybe a heat break, too. 🙂 I am out of home for another week and check all unknown parts again.

Thanks to all!

RE: Inclined nozzle - cause of problem? how to fix?

A final report: The problem has been solved.

It was difficult for me (especially because it was the first time), but doable and for the future I am not afraid anymore. I won't bore you with details, but I changed heatbreak, PTFE and the nozzle, managed to clean the heatblock well (after heating up to about 120 degrees the dirt came off like chewing gum). I had to re-cut the heatblock thread, otherwise I couldn't get the encrusted PLA out. All with cut cable ties, but without loosening the connections, I took much care to bent the cables as less as possible. When reassembling, I screwed the heat sink and heatbreak against the nozzle very tightly by hand and then loosened the nozzle again by holding it against the heatblock, to reattach it heated up with the recommended 2.5 Nm (before that I adjusted my small torque spanner to 2.5 Nm with a torque meter). So now the heatbreak sits much tighter in the heat sink and the heating block than before and I don't have to worry about accidentally loosening it when changing the nozzle. My recommendation would be to loosen the screws on the extruder until the heatbreak can easily rotate in it. That way you can't accidentally loosen the heatbreak when changing the nozzle.

The unclean edge of the overhang and the bending up of the corner at this point no longer occurred with the following TempTower, only massive stringing, but this clearly has to do with PLA that is too wet (weeks open without any drying, I did not expect better results). Apart from that, I'm only surprised that the optimal PLA temperature for me is rather around 200 degrees, but that's probably also an individual experience value for exactly this PLA in this state.

When I then tried to straighten the heatbreak, which was bent by a few degrees, I realised that I couldn't have bent it accidentally: it took far more force than I had ever used on the printer before. In addition, the heatbreak was loose in the heat sink, but sticky in the heat block. The previous owner had simply not done a good job.

Anyway, it was very instructive - and the devices are not made of icing, with the necessary respect for the filigree components you won't break them so quickly.

THX a lot for all hints.

Translated with www.DeepL.com/Translator (free version)