RE: Help with my Mk3S

if it’s the blackout cover file the OP uploaded earlier, it is flat in the 3mf.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Help with my Mk3S

Interesting this thread remains. When your prints are having issues, are you re-playing old GCODE files that were originally sliced for your MK2? Just wondering - cuz that could cause "hey, these gcodes used to work fine" - they need to be re-sliced for the new printer.

That white thing with the support or raft - why is it canted such that it needs support like that? It can be the devil to get a canted bottom to really print well. You want the bottom to be absolutely flat to the bed as much as possible - and that rafting over half of the surface makes me wonder if that surface is perfect zero or off by a few tenths of a degree.

Firstly, it was originally a Mk3 that I upgraded to Mk3S.

The print that you describe as (and looks) white (and is actually grey) is a brand new print. A friend created the cad file last week. I simply PrusaSliced it with the code I uploaded earlier in the thread.

As for "canted", I think it's actually not canted at all. It simply looks like that. It's certainly laid flat to the plate.

In any case, canted or not, old gcode or not, why has that big glob started halfway through the first layer? It makes no sense to me.

RE: Help with my Mk3S

That's what I'm looking for. Usually globbing is something that comes from - too hot, too close to the prior layer - and usually starts out when the first layer Z is too close. Usually bad prints are a factor of initial z - which is the initial squish - are too far from the bed - too round in profile at the individual bead. But in the case of too close the print head will start to build up a glob on the second layer as it dredges into the first layer too far - plowing instead of depositing more.

Too hot can cause a similar globbing problem but it is usually (my experience) accompanied by stringing - spider webs of plastic all over the print and these flow like little gossamer strands so the stick/glob up the print head. Fix for this one is easier - Tune, Nozzle temp lower. Go in 5 degree increments till the stringing stops.

I find that different brands of filaments have different top ends - where the default profiles go for averages. For example, I have some Jayo PETG that prints well from 220 to 240. At 220, it can stand in for PLA if the temp is adjusted on the fly. But the default PETG profile pushes it into 250 range on higher layers - causes stringing for that one filament (so I will make a profile for that)

I have one roll of translucent red PETG that doesn't extrude well until the temp is 260 to 270. I can't wait to use that up it is a pain to switch over to. I now write what I find on the outside of my filament boxes - ideal ranges or profile name.

RE: Help with my Mk3S

That's what I'm looking for. Usually globbing is something that comes from - too hot, too close to the prior layer - and usually starts out when the first layer Z is too close. Usually bad prints are a factor of initial z - which is the initial squish - are too far from the bed - too round in profile at the individual bead. But in the case of too close the print head will start to build up a glob on the second layer as it dredges into the first layer too far - plowing instead of depositing more.

Too hot can cause a similar globbing problem but it is usually (my experience) accompanied by stringing - spider webs of plastic all over the print and these flow like little gossamer strands so the stick/glob up the print head. Fix for this one is easier - Tune, Nozzle temp lower. Go in 5 degree increments till the stringing stops.

That's interesting. I am seeing a few gossamer threads as you describe. Rather than "all over", I'd describe them as sparse. Nonetheless I'll run a few more prints ramping down the temperature each time as you suggest.

As Arnie says.... "I'm coming back again" or something!

RE: Help with my Mk3S

With PETG in particular it may be hard to get rid of some residual stringing. You can spend hours trying to get rid of them. Or recognize that the heat gun is your best friend...

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Help with my Mk3S

@rb14

The steel sheet is always clean. I keep a stock of antiseptic wipes for that reason.

Er, there are marks on the sheet in all your pictures.

Use alcohol wipes for a quick, between prints tidy-up, they will never do the whole job, not everything is soluble in alcohol: so from time to time give it a full scrub.

Clean the sheet with dishwashing detergent (Fairy) and plenty of HOT water, rinse well and dry with a fresh paper towel. Handle by the edges only.

Cheerio,

RE: Help with my Mk3S

@rb14

The steel sheet is always clean. I keep a stock of antiseptic wipes for that reason.

Er, there are marks on the sheet in all your pictures.

There are. They're tiny indentations rather than dirt. I take your point though. The marks are one of the reasons I went and bought a TF26 - the textured sheet. It made no difference.

RE: Help with my Mk3S

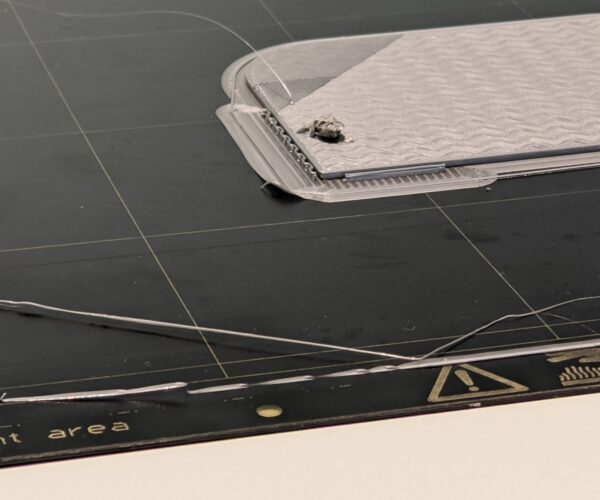

So having reduced the first and subsequent layers down to 205, here's where I stopped the print. It had detected a crash, but self-resumed shortly thereafter. Then I intervened.

I'm with you on the importance of a clean bed and a decent first layer. And I didn't in fact clean the bed properly before trying this print, I just roughly washed it. However up until the upgrade from Mk3 to Mk3S, I had no issues at all. I wish I hadn't done it now!

As you will see in the middle pic, there was some stuttering on the extruder in the initial wipe. The near left corner of the raft(?) has lifted, but the globbing? I can't begin to fathom it. I think there are a few issues here.

RE: Help with my Mk3S

Ignore this post, duplicate from above.

Maybe I should read the posts

Tank you very much!

RE: Help with my Mk3S

I think at his point the OP is not struggling with adhesion (so I don’t think there’s an easy with the plate) but with the bit “globs” he’s seeing.

If the Live Z is correct and there’s no crap on the nozzle/heat block, I would move on to the hot end assembly (filament oozing and creating the glob).

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Help with my Mk3S

I think at his point the OP is not struggling with adhesion (so I don’t think there’s an easy with the plate) but with the bit “globs” he’s seeing.

If the Live Z is correct and there’s no crap on the nozzle/heat block, I would move on to the hot end assembly (filament oozing and creating the glob).

I think you're right about the hot end. Can you give me some pointers?

RE: Help with my Mk3S

Pretty much as described in https://help.prusa3d.com/en/guide/how-to-replace-a-heatbreak-heatsink-heaterblock-mk3s-mk2-5s-mmu2s_16104

Maybe the key steps are 14 and 19 — proper application of thermal paste; 25 — proper positioning of the nozzle, truthful against the heat break, not the heater block, needs a 0.5mm gap; and 26 — correct size PTFE tube, with the round end inside and the conical part outside and properly positioned.

I think these are the most common areas of filament leakage.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Help with my Mk3S

I'm happy to have another go at this, but I have lost count of the number of times I've had the heatblock/sink assembly apart. Replaced loads of bits too. I'll have another go.

RE: Help with my Mk3S

Odd results. I do nto see anything that should cause a crash.

--------------------

Chuck H

3D Printer Review Blog

RE: Help with my Mk3S

Odd results. I do nto see anything that should cause a crash.

No. It's a mystery. I havent yet got down to stripping the hotend for the two millionth time, but I will today or tomorrow. It's really getting me down to be honest. Thanks for looking.

RE: Help with my Mk3S

Hello, can anyone tell me why when I do a printing my printer extrude a little bit of filament before the printing (when it looks for the zero) and then do the correct line of purge? This is a problem because when I want to send a printing I have to stay there because it makes a ball of filament and then the first layer doesn't makes correctly.

Thanks!!

RE: Help with my Mk3S

Pretty much as described in https://help.prusa3d.com/en/guide/how-to-replace-a-heatbreak-heatsink-heaterblock-mk3s-mk2-5s-mmu2s_16104

Maybe the key steps are 14 and 19 — proper application of thermal paste; 25 — proper positioning of the nozzle, truthful against the heat break, not the heater block, needs a 0.5mm gap; and 26 — correct size PTFE tube, with the round end inside and the conical part outside and properly positioned.

I think these are the most common areas of filament leakage.

So an update.

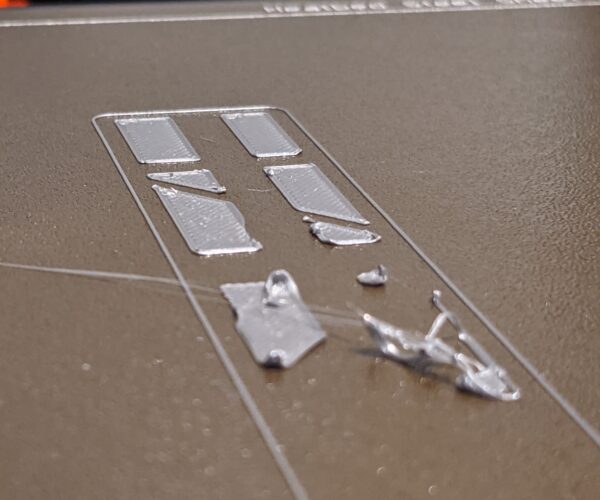

"This is ridiculous" I thought. So, to absolutely rule out the hotend, I bought a preassembled replacement for ludicrous money. It's an E3D v6 for Prusa "1.75mm" "Direct" "24v". Brass 4mm nozzle. I redid the whole calibration thang from start to finish. All good. Printed out the "blackout cover" and it was a disaster on the first layer; exactly the same as before I did all this.

OK, so it MUST be something in the custom Gcode. I'd messed around with it ages ago. completely removed all user profiles. Wizard-ed Prusaslicer from scratch. Deleted all files on my SD card. Resliced the "blackout cover" with everything to standard. Another mess.

Right. Muppet Lab Bob's Project Notebook. Where are you? Found it. Let's use his foolproof ultra-safe start and end custom g-code. Print the "softjaw" again with Bob's recommended custom gcode.

The outcome is below. As is the zipped 3mf file.

This is killing me. Perhaps a slight exaggeration, but only slight.

RE: Help with my Mk3S

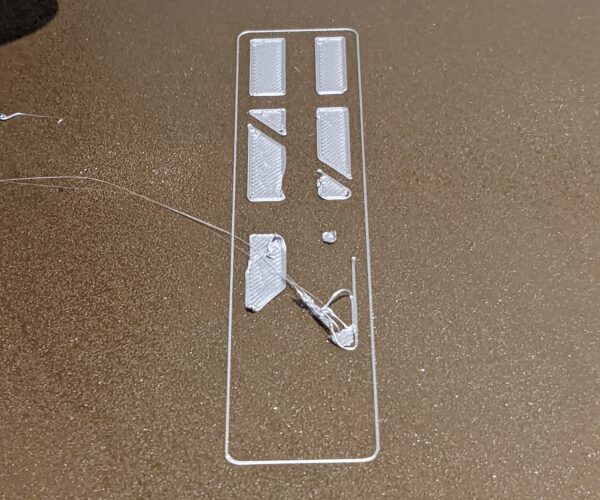

And one more. Had a brainwave. Go to Prusa and download the actual gcode file for the whistle. That's Prusa's own file and their own settings. How hard can it be?

This hard...

RE: Help with my Mk3S

@rb14

Hmm. Are you sure that is not the Mini file?

--------------------

Chuck H

3D Printer Review Blog

RE: Help with my Mk3S

Have you scrubbed you build plate with dish soap?

--------------------

Chuck H

3D Printer Review Blog