first prints issues - uneven quality throughout the first layers

Hi guys,

Probably not the first one with this issue 🙂

So i got myself a prusa mk3s assembled it and ran through different tests. everything was fine (xyz and general equipment audit) then i printed successfully the batman symbol and unsuccessfully the small boat (roof did not succeed, the nozzle hit someparts and created PLA strings and i stopped) . After the unsuccessful try i calibrated again and cleaned the nozzle to my best knowledge. Then i tried the nefertiti bust which failed at around 5 cm height again due to printer hitting the structure. (alledgedly - i didnt see it but again there were strings all across the sculpt and the nozzle)

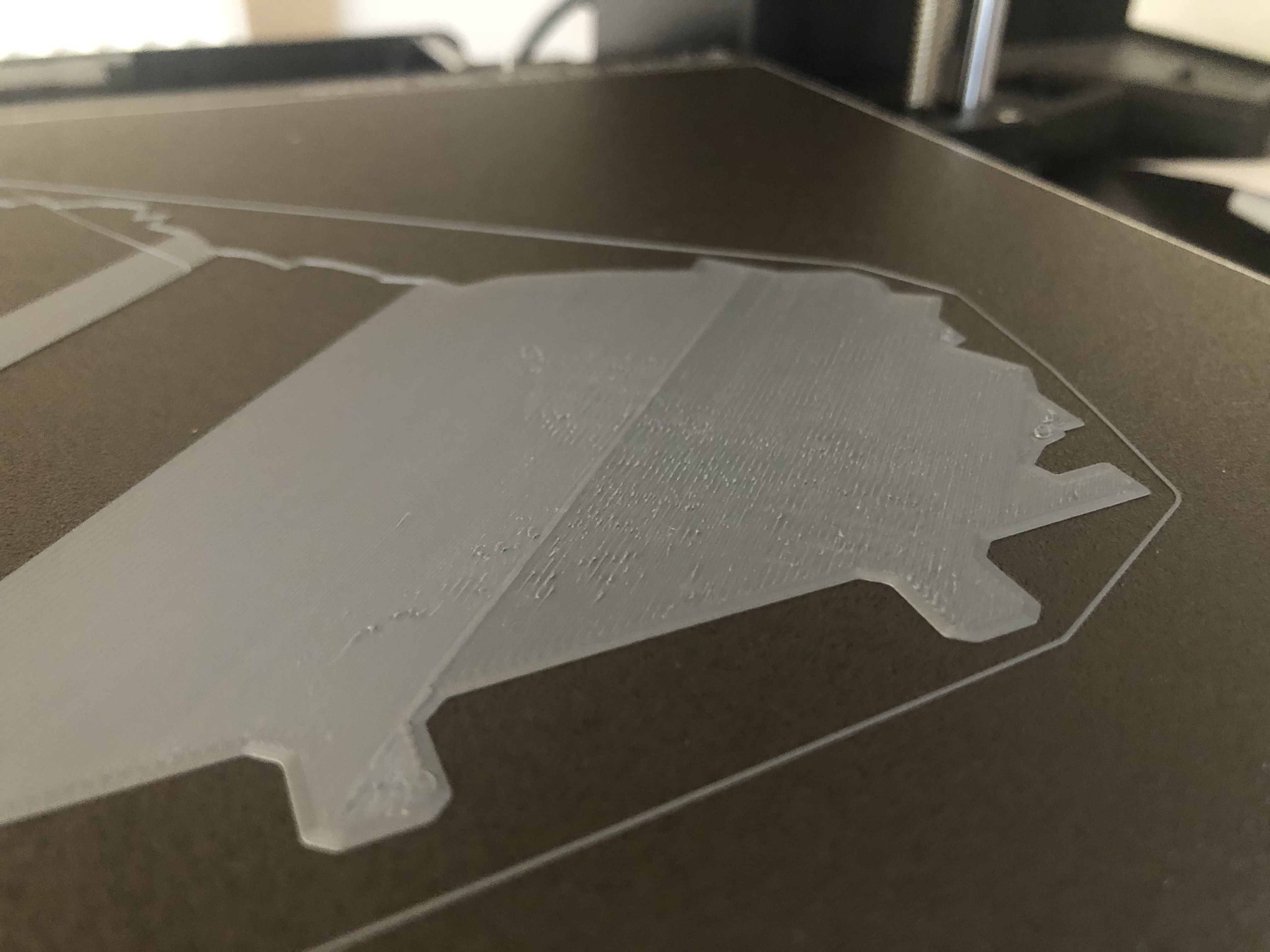

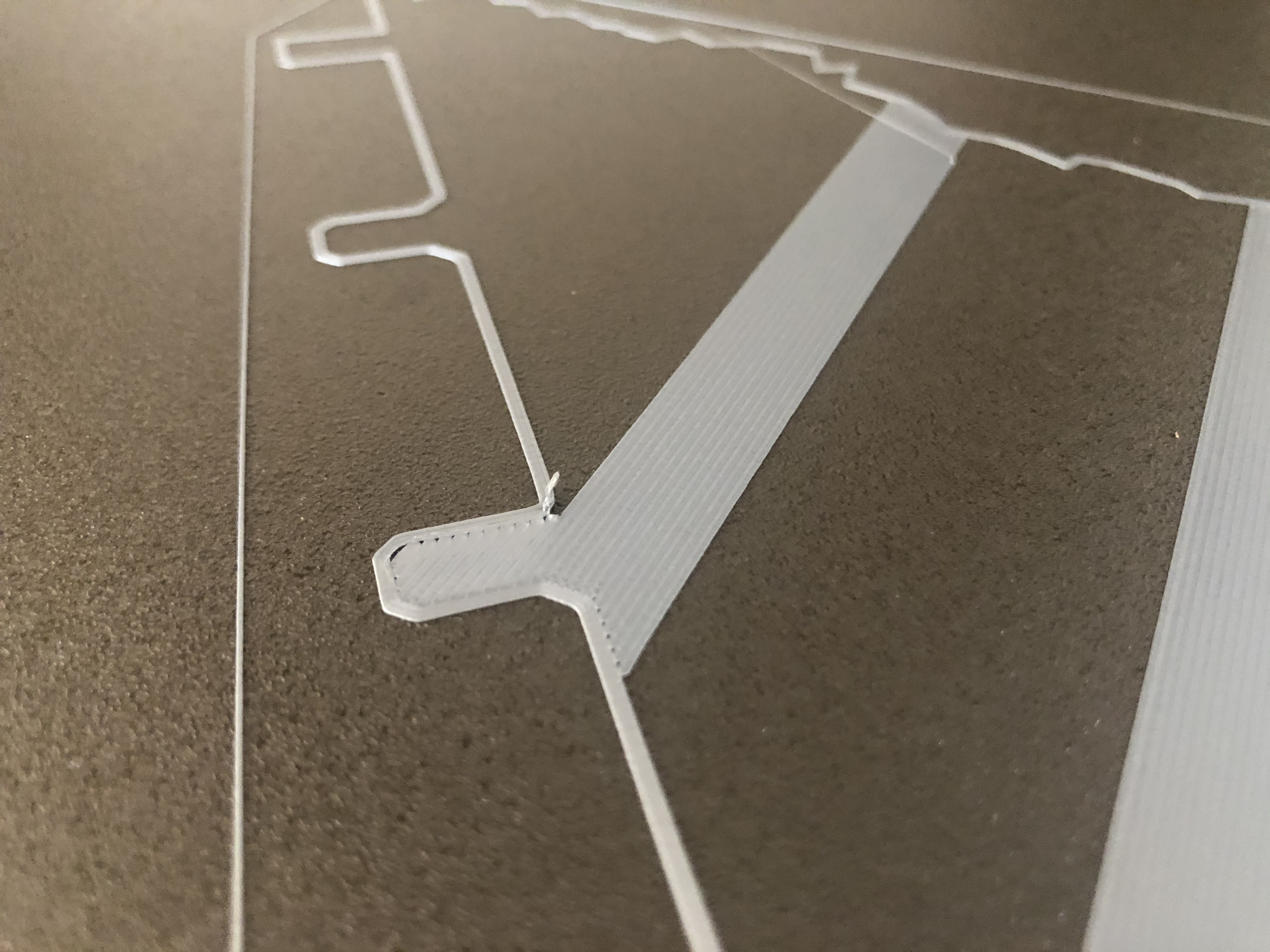

to better identify the issue i chose a very flat structure to print : If you have a look at the first picture, part of this first layers look really smooth and then it gets gritty like the nozzle probably hit the PLA. on the second picture there was a lose end which now stands up after the printer bypassed it again.

Thank you and best regards

RE: first prints issues - uneven quality throughout the first layers

adding the test boat as example

RE: first prints issues - uneven quality throughout the first layers

First pictures looks to low or nit clean bed.

Boat looks to high.

A new sheet will stick less then a used one.

PLA sticks more difficult on a powder coated sheet. Is still possible settings need to be more preciese.

This how I work on a pei sheet(there are always exceptions):

Most important to 3d printing is:

1. 3d print will never be like start and i have the print, there will always be problems!!!!!!

2. A clean sheet, use dish soap, then you can print on it. A few prints you can use alcohol, then again dish soap,

big flat models and models with small footprint on sheet- use glue stick(and not every glue stick is the same,

use one that makes a thin layer), and big flat models and small footprint, use a big brim attach to model so footprint is bigger.

Petg sticks to much on the pei sheet, use window cleaner, this leaves a layer on the bed, so it does not stick to much.

3. To get it stick very good, a 100% first layer is very important, see youtube for movie on this.

Every new print watch the first layer, and look if it is 100%, this will also prevent a big ball of filament on your nozzle wenn model let loose during printing.

Extra: (normally not needed).

First layer, print hotter.

First layer slower.

Bed more heat.

Most problems are first layer to get this 100%.

Bad filament is possible, or filament with water inside.

Move extruder to the top and extrude filament, it should go straight down(if not, nozzle possible blocked),

it should be thick enough(if not, nozzle possible blocked), (do a cold pull),

if Bubbling during extrusion then it has to much water inside.

Check after the first layer is ready, then you see if it sticking enough, and not releasing and sticking to the nozzle.