First Layer: corner issues. Expected or something wrong?

Hi,

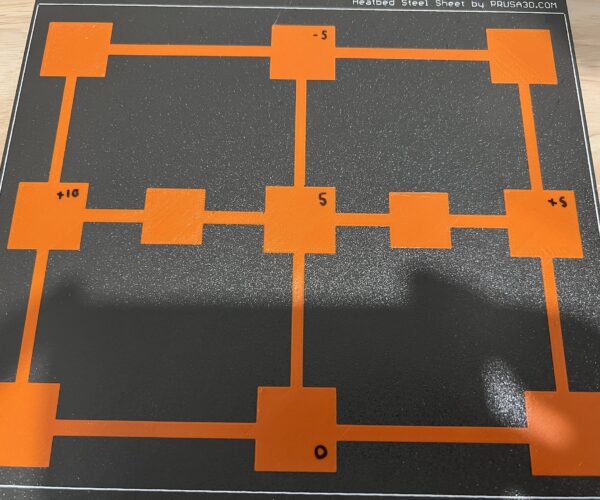

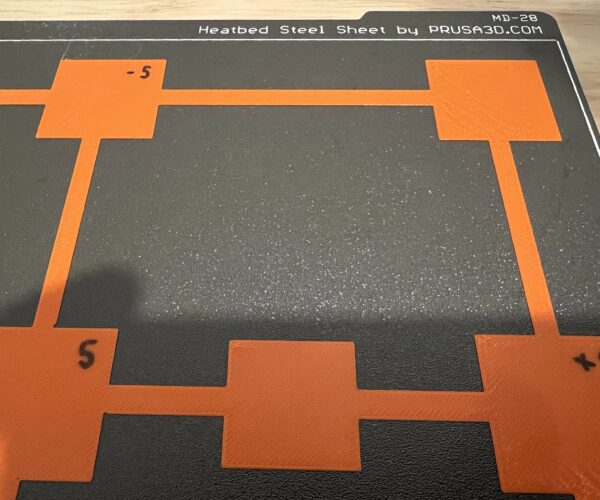

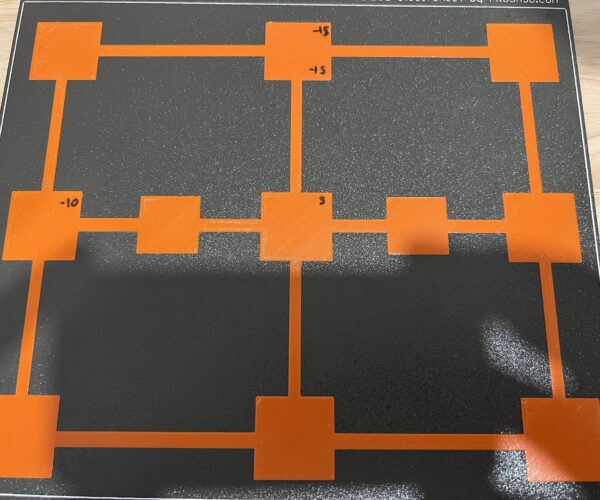

I am trying to understand if I'm simply pursuing unobtainable results of if I am doing something wrong. The MK3S+ was bought pre-assembled and PLA didn't have issues (though I haven't printed anything large). This issue is with Prusament PETG: I had to lower the PINDA sensor due to snagging the paper, and my live adjust is pretty big (-1.883 with textured steel sheet). I'm quite happy with how it prints on the center, but the edges have more issues. These latest tests are with a silicone sock (pro) which has helped immensely with the PETG curling in on itself.

I am using mostly stock settings in Super Slicer for prusament PETG, aside from the custom gcode that prevents heating fully until after bed level.

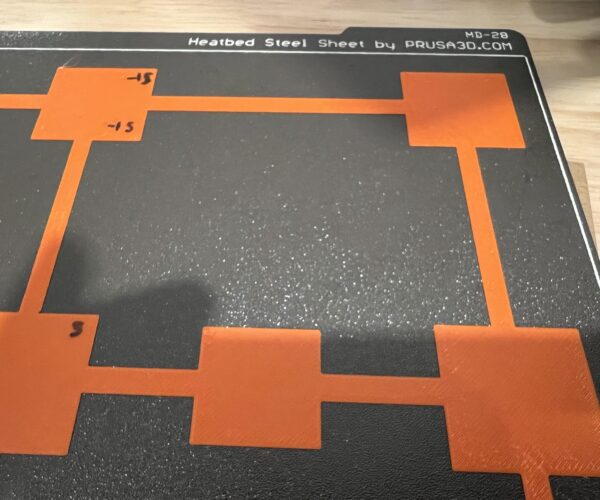

The top right corner is giving the most issues, I've attempting the bed level correction but honestly can't tell if I am doing much (I haven't done the widest of variations). Just looking for a sanity check on if the waves and bumpy texture I see in top right (last attempt may be best) are to be expected or if something else is going on. Thanks. Images below (latest attempts first aside from solo square).

RE:

Not too bad. Are you using 7x7 mesh bed levelling? (LCD menu) If not try it and run that print again.

Get the centre right and the rest will usually look after itself.

Cheerio,

RE: First Layer: corner issues. Expected or something wrong?

Yes, I am using 7x7 bed leveling. So it sounds like my concern about the waviness and bumps on the edges (mainly that top right section) may be overblown?

I am assuming this is a relatively new machine. Your first picture looks acceptable. The basic configuration procedure is to dial down until you begin to see wavy marks and drags and then back off until they just stop. Most people who resort to silicon socks would do as well to concentrate on cleaning the print-sheet rigorously.

Your rear right corner is a little low but for now I wouldn't worry about it. If a large area were picking up like that it would indicate a too-low Z setting and you would be risking blob-of-doom failures. A small area is less likely to accumulate too much scrapings in the first pass.

For now let's concentrate on getting a basic working machine and producing some acceptable prints. Once it is running it will shake down and irregularities may change. In a month, when you do your regular maintenance, run the Z calibration again and you may find improvements - or not.

Come back here if problems persist.

In the meanwhile prints that use that area of the bed may have a slightly poor finish on their underside but they should still stick OK. I would avoid placing small parts wholly on that part of the bed for a while.

Cheerio,

What exactly are you trying to achieve / dial in?

First layer calibration, mesh bed leveling and the endeavor to get the print bed as parallel to the x and y axis are three different things.

First layer calibration sets the distance between the z position where PINDA triggers and the print bed. This gives the printer the ability to get the nozzle to the exact height for the first layer. The value is the same all over the print bed (!!) there is only one value!

Then there is mesh bed leveling, it measures the different z positions at which the PINDA triggers all over the bed. Meaning it measures how close to parallel your bed is to your x and y axis (it does NOT measure if its level). The measured values are interpolated over the bed and used to correct the z position during print. Meaning the z-offset (from first layer calibration, always the same) and the correction from bed leveling (interpolated to the respective x/y position) is used to position the nozzle at the correct height everywhere on your bed.

Last but not least: You can use different methods to get your bed more parallel to the x/y axis as it is when using the stock bed. For example the nylok-mod with it's corresponding octoprint plugin or something else. By doing this you reduce the corrections the printer measures during mesh bed leveling and therefore you reduce the offset your printer adds during printing. This results in more precise parts being printed (with a less "level" bed your printed part is basically adjusted to fit the bend or bulged bed). But what you don't do by mechanically adjusting the bed is changing the first layer in specific areas of the bed because mesh bed leveling would compensate for that. If you want to level your bed manually, you need to switch of mesh bedleveling and good luck getting that done better than the printer with the PINDA measurements...

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First Layer: corner issues. Expected or something wrong?

The thing is though, even if the bed was perfectly flat, perfectly parallel to the x/y axis if the power coating thickness on the steel sheet varied you would STILL get slight variances to the squish of the first layer.

The PINDA is detecting the steel sheet and so creating the mesh based on that. This takes care of out of square beds and non flat beds by compensating for those in software (up to a certain point). But nothing can help with a non uniform power coating on a sheet.

Personally with the level of details in the pictures then I'd say thats what we are seeing. Hard to be completely sure without seeing things in person though.

RE: First Layer: corner issues. Expected or something wrong?

The thing is though, even if the bed was perfectly flat, perfectly parallel to the x/y axis if the power coating thickness on the steel sheet varied you would STILL get slight variances to the squish of the first layer.

True, but there is no way to compensate for that, if you adjust the bed you also adjust the steel sheet and therefore the point where PINDA triggers so mesh bedleveling would readjust the adjustment back to the previous height...

Same goes for the precision of PINDA, it's just not perfect and varies a few microns every time it measures at the same point.

Makes at least two reasons for not worrying too much about "leveling" the bed beyond a certain point. There are several limits to what you can achieve. Do the first layer calibration and let mesh bed leveling take care of the rest...

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First Layer: corner issues. Expected or something wrong?

Robin that was my entire point. You can only go so far. Everything we have and do with the current setup does not take thickness of the pei layer into account, so don't obsess. The smooth sheets as its a sticker are more uniform in my opinion though so if you are doing anything to accurize your bed flatness then I would use a smooth sheet for it.

On the point about the PINDA, I agree. Its also why I prefer the old PINDA and not the superPINDA. The old one was more effected by temperatures BUT it had a thermistor in there that allowed you to read its current temperature. With that you can always perform the mesh levelling when it gets to a specific temperature. If you preheat your bed for around 10 minutes to let thermal expansion occur and settle and also preheat the pinda (with the bed) until it gets to the defined temperature before doing to mesh process then you can get some amazingly consistent first layers with an original MK3. I wouldn't 'upgrade' to a superPINDA if you paid me 🙂

Of course when the new XL is released with the strain sensor on the hot end then all the accumulated 'wisdom' we have will go out the window 🙂 A whole new set of stuff to learn.

RE:

I am just surprised about the many bed leveling threads and different methods to adjust the first layer. That's all. It looks like a lot of people spend a lot of time adjusting things that can not be adjusted - I just wanted to save them some time 🙂

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First Layer: corner issues. Expected or something wrong?

Thanks to everyone for responding. I've removed any attempt at compensation for the edges and will take the very clean center area as a win... or I'll try that silicone mod since I actually have some appropriate tubing lying around.