Filament Pressure and Failed Print

Hello, second (of the same) print failed, the filament extrusion stopped mid print:

I think this is the problem:

Basically the screws with the spring didn't screw together in the holes, so I had to use the nut. However, with the nut, too much pressure was generated. The filament gets damaged inside, I noticed that unloading it. So I removed the springs and screwed together with the nuts again, this time I get less pressure (but still a bad noise comes from the extruder).

The prints still come out great, but now this one failed.

Retraction: 0.8mm speed 35mm/s

Suggestions?

Re: Filament Pressure and Failed Print

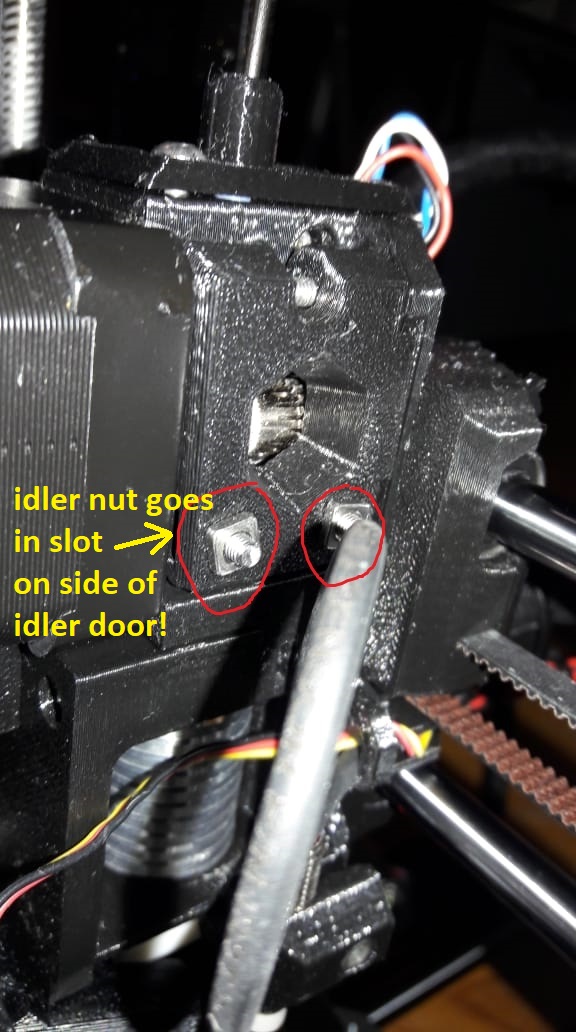

That looks WAY too tight. The nuts should go in the little slots on the side, see this picture: https://manual.prusa3d.com/Guide/5.+E-axis+assembly+(textile+sleeve)/822?lang=en#s14066

Re: Filament Pressure and Failed Print

Hi Simone,

you have assembled the extruder idler trap door, incorrectly.

the yellow arrow in the picture above shows where one nut should go, there is a similar slot on the other side, for the second nut!

below, is the diagram from the build manual

in this diagram the red arrows show the nuts partially installed.

please put the nuts in the correct place, then re install the springs, and you should have a much improved experience!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Filament Pressure and Failed Print

...and while you're in there , you might want to put some of that white lithium grease (the stuff that doesn't creep around, you don't want lubricant getting onto filament) on those little bearing that hide inside the passive bondtech gear attached to that trap door. I even put some on the teeth of the gear itself carefully.

Re: Filament Pressure and Failed Print

Ok thanks, I didn't put the nuts or they slipped away. However, even if now the gears don't comrpess the filament and they don't produce that noise anymore, I got the same problem as before, the extruder jams middle print. In particular, I noticed that the ironing triggers this.

...and while you're in there , you might want to put some of that white lithium grease (the stuff that doesn't creep around, you don't want lubricant getting onto filament) on those little bearing that hide inside the passive bondtech gear attached to that trap door. I even put some on the teeth of the gear itself carefully.

Do you mean the 2 gears that push the filament inside?

Re: Filament Pressure and Failed Print

Are you using Slic3r?. Is your peinter standard?

Try reducing the retraction to 0.6mm or 0 .4mm

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Filament Pressure and Failed Print

Are you using Slic3r?. Is your peinter standard?

Try reducing the retraction to 0.6mm or 0 .4mm

Regards Joan

Idk what standard means, it's a standard mk3 kit.

I'm using Cura 3.3, the PLA is Anycubic Black. I noticed that while extruding it makes "pop" sound, like when there is umidity inside, maybe that's the reason. Really strange, the PLA was sealed 🙁

Now I'm tryng the same print same gcode with flashforge pla black.

Re: Filament Pressure and Failed Print

Hi Simone,

lots of us change components... sometimes for good reasons, sometimes. just because we can!

My printer is mostly standard kit,

all cables are inside mesh braid sleeving, instead of curly wrap,

the X motor has a bracket on the back to support the weight of the braiding and cables, rather than letting them pull on the motor wires!

I have a 0.4mm stainless nozzle, because it was available when my brass nozzle wore out/ got messy! usually add 5degrees to filament temperature to compensate for reduced heat transfer... I have a thermocouple thermometer on order to check the temperatures!

I have a revised part fan shroud... seems to cool better,

I have a scoop on my part fan intake, facing away from the heatbed, probably placebo effect...

and a visualiser wheel on my extruder motor shaft to show movement...

oh almost forgot... a double size whatsit to block the filament sensor cleaning hole. the original is difficult to manage, with long finger nails

some modifications affect the running of the printer, which is why asked

the popping sounds unusual, did the other filament work better.

do you have Prusa profiles, for Cura?

do you have the latest firmware on the printer?

have you tried Slic3r Prusa edition?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK