Filament extrusion from Nozzle Threads?

Hi,

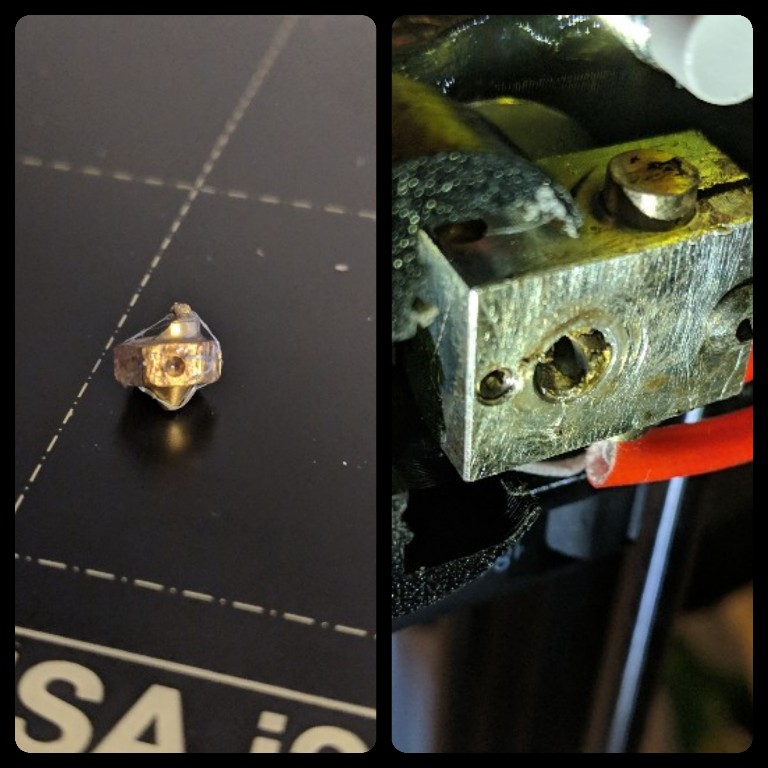

I just got a new MK3S kit and put it together. Going through calibration, after a few tweaks, everything looks good. The only problem I'm having is that a blob of filament starts to build around the nozzle. But wait! not that blob. The blob starts to build coming from the nozzle threads (see attached picture). It takes a few minutes and then keeps growing to the point that it will interfere with the print and create that blob. Blob creates blob.

I've tried to clean and take off the nozzle, then re-tighten it. It still happens. It extrudes fine otherwise. I don't think it is the nozzle being loose. Maybe it's a thread issue? Should I just get a new nozzle or is there something else that i'm not thinking of. Has anyone else had this problem?

I tried to do a search but the only things I see come up are the other blob issue. It's isn't an over use thing since this happened from the beginning.

Any help would be appreciated,

Thanks!

Re: Filament extrusion from Nozzle Threads?

https://e3d-online.dozuki.com/Guide/V6+Assembly/6?lang=en

the parts of the hot end have to be assembled in sequence and the final tightening done with the hotend at a high temperature

from disassembled

1. the nozzle is installed leaving a gap of about 0.5 to 1.0mm between the hex part of the nozzle and the bottom of the heater block

2. (optional...a tiny bit of copper never seize is placed) on the the short threaded part of the heat brake and it is screwed in till it bottoms on the threads of the nozzle.

3. the heater block assembly is screwed into the heatsink with artic silver on the heat brake that threads into the heatsink (or similar heatsink paste as used between computer processors and their heat sink)

the rest of the hot end is assembled ( as in the linked dozuki above) heater and thermistor installed and the PTFE tube seated tightly to the top of the heat brake and locked in place by the colet lock and its clip

if you don't have this blue clip in your kit (it is frequently missing) you can make one from plastic milk bottle with an exacto knife or get a friend to print one for you there are several versions on thingverse

heat the hotend to 275 and tighten the nozzle not much strength is needed just finger tight will be fine. 10 inch pounds or 1 newton torque but it must be done hot...

in your place I would print the collet clip first to be sure to have it fro the reassembly.

all this will properly fix that plastic leak... but it you wish you can try to heat it up just as it is and try to tighten the nozzle against the heat brake at a guess you have about a 4 out of 5 chance of it working.

Re: Filament extrusion from Nozzle Threads?

Thank you for the reply. I was going to try your second option first, since it involved less work. I unloaded the filament (via the settings), then heated the nozzle up to 285 as the change the nozzle video instructs. When I went to remove it, the end broke off! Now I have the threaded portion stuck inside the heat brake. Sigh. I was using a 7 mm socket too.

So maybe it was an issue with the nozzle itself? I'm not sure how I'm going to get the threads out now or if I'll have to get a new heat brake and nozzle?

edit: attached photo

Re: Filament extrusion from Nozzle Threads?

if you can get the heat break loose from the heat block, the threads remaining from the nozzle should be free and can be gently turned out with something - small screwdriver, pick, etc. Make sure you try to loosen the heat break while hot or it may break as well.

(unless you're really unlucky and they're cemented in by leaked cooked plastic)...

Re: Filament extrusion from Nozzle Threads?

as prusa provides the e3d v6 as an assembled unit with the kit I would take this to the chat help system

contact prusa online chat system 24/7 support

log into your account on one of the prusa store pages and in the bottom right corner you will see the Chat system box click in it enter your Invoice number for you Prusa and start the chat system

be ready to provide the pictures of the leak and of the way it broke into the chat and you have a good chance that they will send you a new hot end assembly under warranty. if they decline ask to have a supervisor join the chat...

In general they do an excellent job and will take good care of you.

that nozzle should not snap with only 10 inch pounds of torque applied (1 Newton)

However if all that fails you would need to source some new parts and that depends on where in the world you are located.

in the usa I use Printedsolid.com they even have the special Prusa e3d v6 heat brake used in the MK3 and MK3s but given your kit came with a leaking nozzle I think Prusa should send you a replacement hot end.

Re: Filament extrusion from Nozzle Threads?

Thanks for the help vintagepc and randolph.l

I'll post what happens so if someone else comes across this issue/thread, hopefully it helps them.

Re: Filament extrusion from Nozzle Threads?

Update: After speaking with someone via the 24/7 chat system, they think that it was "most likely an assembly mistake on E3D's end", so they will be sending me a new hot end. Thanks for the help