Extruder producing a 0.2mm bead on First Layer calibration

Just going through initial post-build calibration. On First Layer calibration, the prime line looks about right (based on my total lack of knowledge), but the calibration pattern comes out as a thin thread -- a 0.21 mm strand, according to a micrometer. Do I need to increase the extrusion speed under settings?

I've checked that the little set screw on the drive gear is snug on the flat side of the motor shaft. Help appreciated.

RE: Extruder producing a 0.2mm bead on First Layer calibration

Are you referring to the Live-Z extrusion? The line should hold firmly to the PEI during printed and have a somewhat squished oval/stadium cross section.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Extruder producing a 0.2mm bead on First Layer calibration

The diameter of the extrusion is too small to even adjust live Z without a microscope. Seriously -- it's extruding a skinny-ass line that is so thin that there's no way to tell with the naked eye whether or not it is slightly squashed. Any idea what the diameter of a normal extruded line is supposed to be before it's slightly squashed? When I initially load the filament and a bit of filament is extruded, it emerges with a diameter of 0.8 mm -- which seems reasonable. But as soon as I try to print anything, the filament emerges from the extruder at 0.2mm. Is this normal?

RE: Extruder producing a 0.2mm bead on First Layer calibration

@mcq

It's always safe to raise the setting on live-adjust, try moving it up and see if that helps.

I take it you went through the zip-tie process okay?

RE: Extruder producing a 0.2mm bead on First Layer calibration

Assuming you're talking about the Live-Z calibration step, if the extrusion is loose, you are probably way too high. Go lower (more negative) until the extrusion starts sticking to the PEI sheet.

Go through the on-board routine once to completion, then try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the onboard routine and much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.

More notes on Live-Z here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Extruder producing a 0.2mm bead on First Layer calibration

Did the zip-tie test. Is it normal for the extrusion during a print to be about 1/5 the diameter of the extrusion on the prime line? Because during the live-Z calibration, that is what's happening. And if I adjust Z for the prime line, I'm too high for the rest of the print to stick. But if I crank live Z (currently at -1.750) down to where I can get the extrusion for the print to adhere to the bed, the prime line ends up being a flattened smear on the next attempt, because it's so much larger than the lines in the print.

RE: Extruder producing a 0.2mm bead on First Layer calibration

Let me put this another way. The problem seems to be with the extruder not extruding enough filament. I'm not having a problem with the live-Z adjust. The problem is that too little filament is being extruded. Does anyone have a real number for the nominal diameter of the extrusion during a typical print?

RE: Extruder producing a 0.2mm bead on First Layer calibration

Pics would help.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Extruder producing a 0.2mm bead on First Layer calibration

@bobstro

I have to agree. It is sometimes impossible to visualize the complexity of the problem without a photo.

--------------------

Chuck H

3D Printer Review Blog

RE: Extruder producing a 0.2mm bead on First Layer calibration

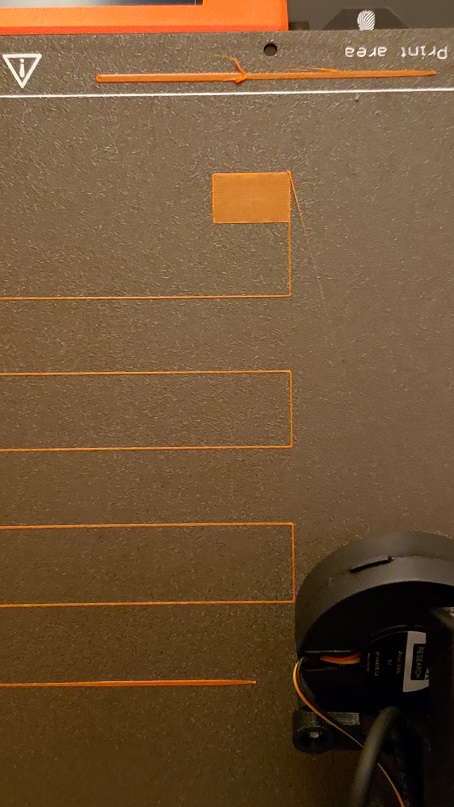

@bobstro, et al -- Sorry if I've been a little unclear. Notice the difference in width of the prime line and the first stroke of the pattern in comparison to the rest of the pattern. The filament in the majority of the pattern is so thin that I've got z at -1.800 in order to get it to stick. But because the prime and the first stroke of the pattern are so much thicker than the rest of the pattern, they are overly squished. Is it typical for the prime to be so much thicker than the rest of the pattern? If so, then I'm hyperventilating about nothing. And just as an aside, I went into the Tune menu and bumped up the flow to 150 for this print.

RE: Extruder producing a 0.2mm bead on First Layer calibration

When I initially load the filament and a bit of filament is extruded, it emerges with a diameter of 0.8 mm -- which seems reasonable. But as soon as I try to print anything, the filament emerges from the extruder at 0.2mm. Is this normal?

Your printer is working properly. The first so-called primer string is much thicker. When you then start writing, the first layer should be approximately 0.2 mm thick, which corresponds approximately to the thickness of two office papers.

Your prints should not be as strong as the initial primer string.

Bear MK3 with Bondtech extruder

RE: Extruder producing a 0.2mm bead on First Layer calibration

@rh_dreambox

Thanks for the clarity. I appreciate all the help from everyone who responded.