Brand New (wet?) Prusament PLA Filament

I got my assembled MK3S+ 3 days ago. Fun machine for sure. But I noticed recently that the Marble Grey PLA has been giving me some stringing issues. I firmly believe new rolls of any brand don’t necessarily mean they are completely dry.

I started with very “boxy” prints, nothing with fine details and without lots of jumping. Today I tried to print the mini octopus print-in-place print, and the articulations weren’t moving as much because of stringing. I was able to fix it by using a heat gun. I’d say I got 70–80% of the strings. Also, just before the print started, whenever the nozzle was heating up, I kept hearing popping noises (a pop every 30–40 seconds).

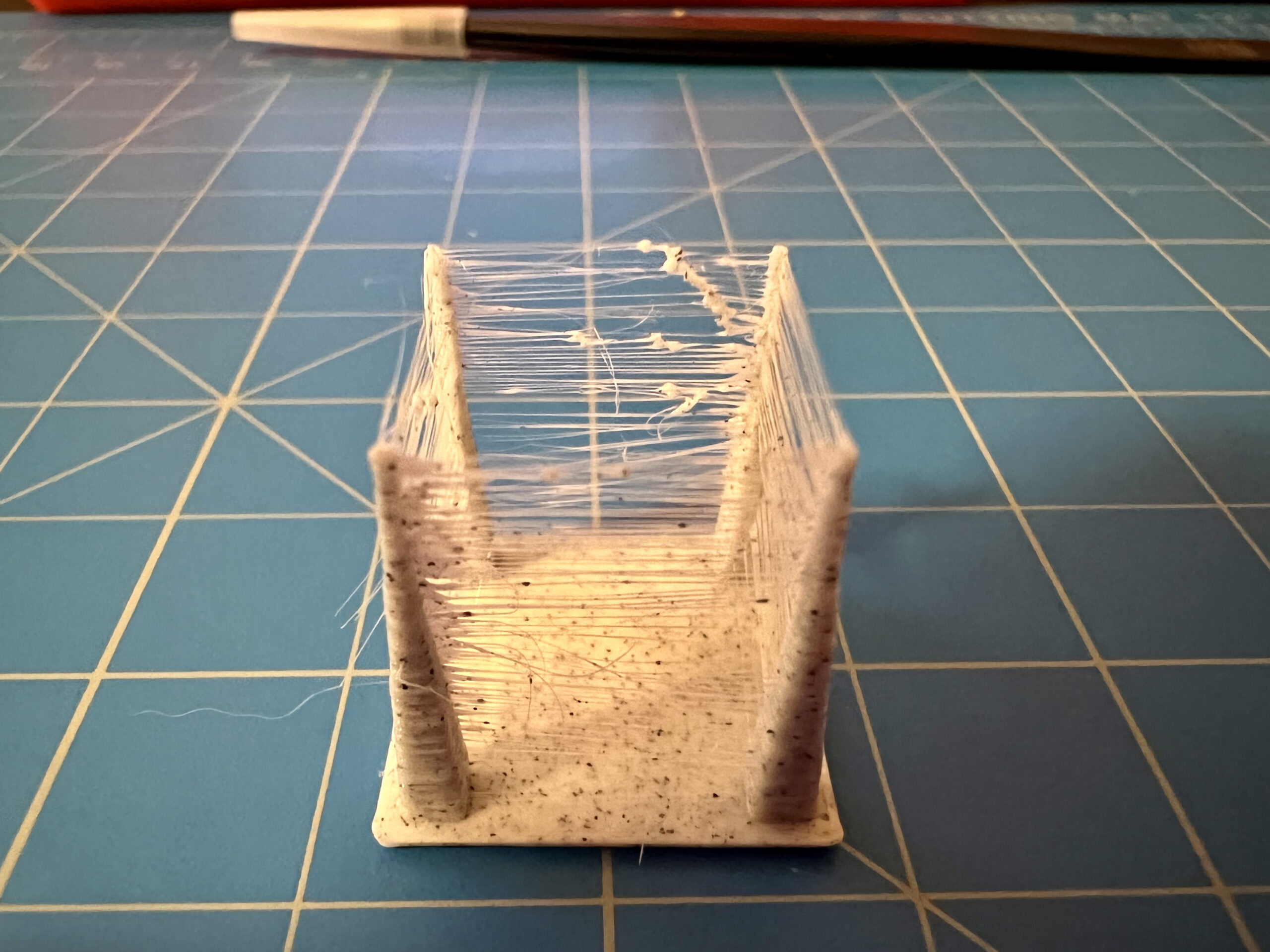

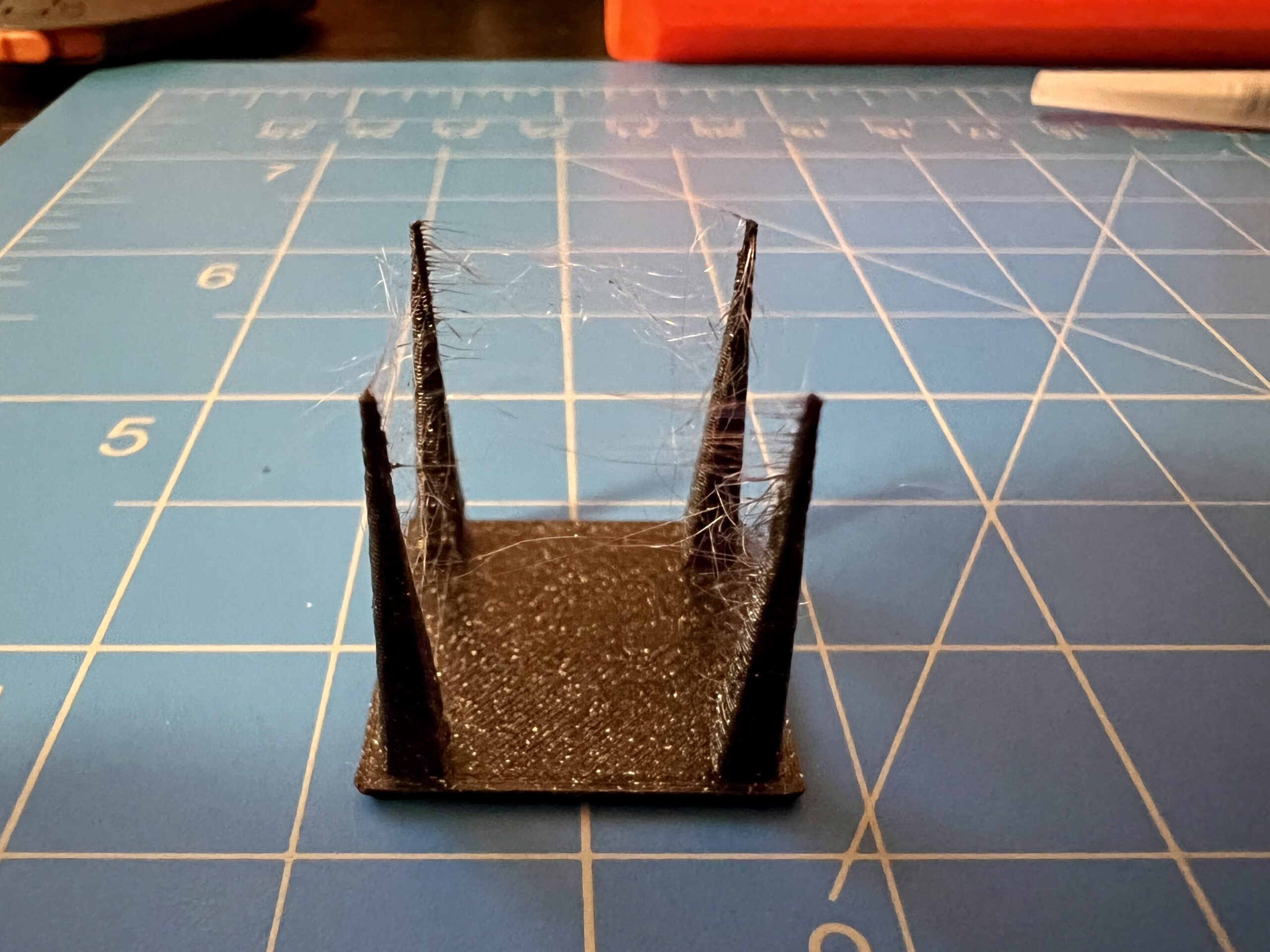

I printed a string test to see, and it wasn’t good.

Just out of morbid curiosity, I opened a new roll (Galaxy Black PLA), immediately loaded it, and did the same test. There were far fewer strings, but those were thin and fine, like cobwebs.

The Marble Grey PLA was sitting atop the printer for about two days in a room with an RH of 49–51%. Also, I have not changed a single setting on the printer/slicer apart from the first layer calibration. I am also using the Prusament PLA profile for each of the rolls.

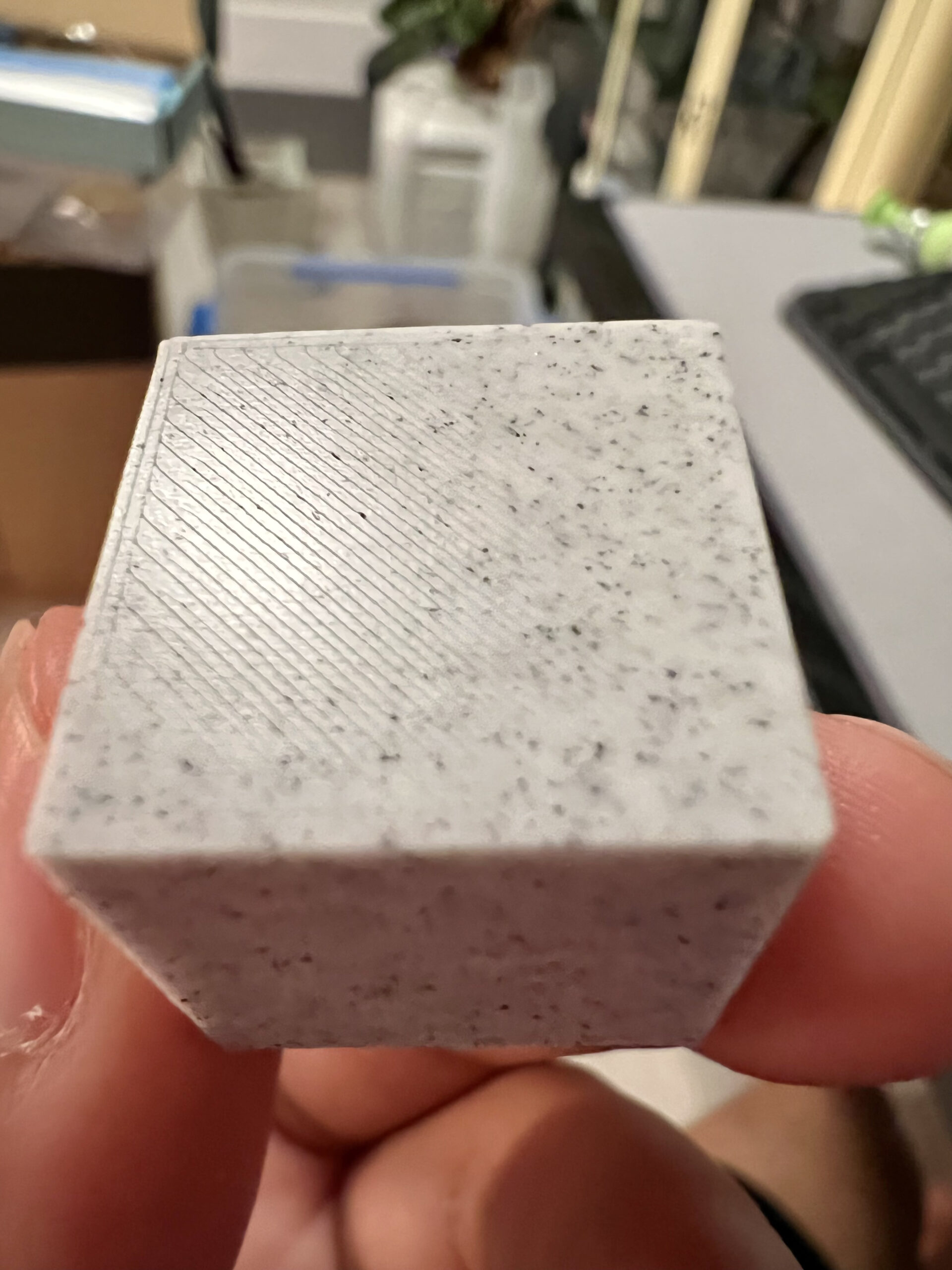

Apart from the stringy mess, the “boxy” prints come out great. I am also attaching a picture of the bottom layer of an XYZ calibration cube to show the first layer. It shines like glass, and there’s no waviness.

I think my next step would be to dry both filaments and take them from there. Or is there anything else I should keep in mind?

RE:

Filaments can absorb enough moisture to cause trouble in just a few hours.

Thomas Sanladerer tests filament drying:

After a week exposed in a room with a dehumidifier running there was noticeable deterioration of PLA finish...

CNC Kitchen - skip to 7.40 for time to fully hydrate results.

Cheerio,

RE:

During the pandemic, I converted one of my storage dry boxes into a makeshift dehydrator.

Shortly after I did that, we got one of those Ninja Cookers as a kitchen toy, and it has a dehydrate option.

When I think I have a damp spool, or one that has not been used for a while, just to be sure, I will run it overnight (12 hours on timer) at 120F/49C and that does the trick.

I've also found that the degree of moisture absorbing varies from brand to brand. For example, a spool of the Ultimaker brand PVA (soluble support) ran exposed to room air for a few months and did not show any ill effects, while the (cheaper) Dynamism house brand PVA soaks up room humidity like a sponge and needs to be re-dried before any print that requires it.