Adhesion issues and print quality.

Adhesion issues and print quaty

RE: Adhesion issues and print quality.

Wow this is a lot of information! -- let me see If I can assess the underlining problem here... nope, not enough details

Stock MK4S with FW 6.2.6

RE: Adhesion issues and print quality.

Bugger. I spent 40 minutes describing the problem, anubmitted photos.

All vanished.

Maybe it's the phone interface. I'll try again from the laptop

Pad

RE: Adhesion issues and print quality.

I can't seem to make this forum post work.I'm really sorry. Either the post goes when I start it, or when I attach a photo, but not when I want it to go.

So here's the text to go with the previous 3 posts that I have already typed once - who knows where it went?

I've had a i3 Mk3 for 2 weeks now, and when I print on the left side of the bed the prints seem to come out well.

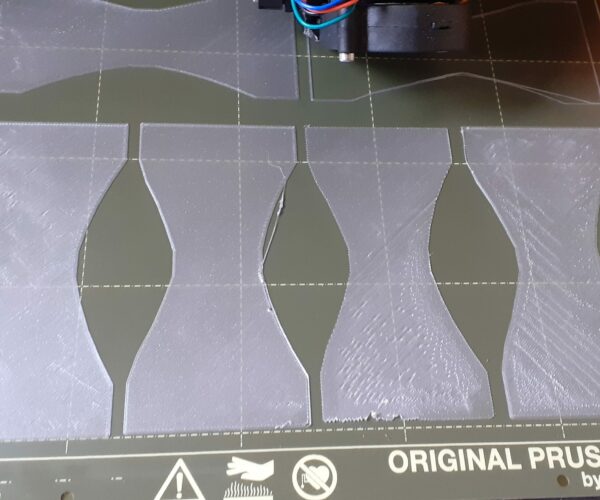

If I want multiple items (these are face mask holders to prevent ear pain) then I put 6 up and use the whole bed. Often these prints fail, usually at the right hand side of the bed.

I am printing with PLA, (Prusament) and the hotend and bed temperatures are 215/60°.

Speed is 100% and the Z offset is -0.642 as set up on a couple of calibrations. The prints on the right, and especially at the back, are noisier than the others as if there's a vertical interference going on, but the printer is happy with the 9 point calibration every time.

I'm printing on themagnetic metal bed that came with the printer. I cleaned it prior to the print with PureChem Industrial 99% pure Isopropanol on a kitchen paper towel, and then finished off with water and a dry rub with the same kitchen towel.

On this run, the skirt came adrift as soon as it was placed, then the back left and front left first layers went down after the 2-layer outlines with no problem. After that, when it started to print the outline for the middle left one, that came adrift also, and the printing as you can see becomes increasingly rough as it moves right, until the rightmost one at the front which is OK. The rear one on the right has been noisy to print because the nozzle is banging into the lumps in it.

Should I reach for the Pritt glue stick and the hair drier here, or is there something else I should be looking at?

Many thanks

Pad

RE: Adhesion issues and print quality.

maybe the universe is telling you you are posting in the wrong section of the forum: You are in the subsection of the prusa MINI.

I hope someone there can assist you with your issue (I hope you clean the bed with IPA when it is cold, spraying IPA on a warm bed evaporates the IPA and leaving the 1% -- clean the bed with water and soap dry it with a clean paper towel - lay it on the printer - clean it with IPA (and another clean paper towel and try again)

hope someone on the MK3 side can assist you further...

Stock MK4S with FW 6.2.6

RE: Adhesion issues and print quality.

Hi,

Well definately appears that you have an issue with your mesh bed leveling. First run the xyz calibration routine. Go to your menu and select settings > mesh bed leveling and use the 7x7 leveling. What I do is that I slice and print this https://www.thingiverse.com/thing:2899815 . As this starts I use the live z-axis leveling to get the tracks to stay on the bed and then as the patches are printing adjust my z-axis until I get a flat almost paper patch without ridges or gauging. Repeating if necessary until I get a good print.

Good luck and best regards,

Phil

Stay safe and healthy, Phil

RE: Adhesion issues and print quality.

@oxygen

Thanks. It was a bad night's sleep, but I didn't think I wasn't functioning until this lot!!

I'll post it in the right place in a minute. I didn't realise that I had to clean it cold - that's a surprise to the system, but of course, the alcohol would evaporate very rapidly at 60°C, boiling as it does at just over 80°.

All the best,

Pad

RE: Adhesion issues and print quality.

@pcweber

Thanks Phil.

I have calibrated it til I'm blue in the face, but I'll gladly have another bash - that looks like a good file to play with, too.

Currently I've got it printing the whole lot again with a generous coating of stick glue, and it's holding up well.

I uploaded the stl file for the item yesterday as a "thing", so you can see what I'm up to if you're interested.

I wouldn't expect to need adhesive adjuncts when printing flat items with big flat footprints on the bed, though, so there must be something else up. I'll check the nozzle too - It has been bashing into some displaced prints today, and may be distorted.

Is it usual for it to incontinently dribble a couple of inches of filament while heating up? Mine does it every time.

Pad

RE: Adhesion issues and print quality.

That dribble could be the filament is too hot, there should be zero dribble. There should be no filament in the nozzle to dribble while the hot end is heating up. Clean the nozzle and the do a cold pull and see if you have any residue before you print again.

Phil

Stay safe and healthy, Phil

RE: Adhesion issues and print quality.

Hi Phil,

Thanks for your help.

I think it will be because I sometimes don't remove the filament after a print. Because I've just bought it, the next print is only an hour or so away, quite often, so I sometimes leave it set up.

So when it heats up, there's filament there to dribble.

To be fair, sometimes I'm not about when a print finished, and it cools down in my absence with the same effect.

I will make more effort to avoid that.

Is a cold pull the act of having the filament out of the hotend from above without heating? Wouldn't that harm the hotend?

Pad

RE: Adhesion issues and print quality.

Remember the min has different start up sequence to the mk3 which is the printer in question, even though we are in the mini forum. The mini has a preheat to 170 degrees before it mesh levels, the standard start gcode for the mk3 doesn’t have that 2 stage warmup but it’s easy to add it if you want. Bobs website here - http://projects.ttlexceeded.com/3dprinting_prusaslicer_gcode.html has some nice annotated notes on what to add for the mk3. So it is quite possible for the mk3 to have filament leak before it starts printing if you are using the defaults. I suspect at some point the mk3 defaults will also get updated by Prusa to match the mini.

A cold pull is performed at a cooler temperature, so that the filament is soft but not fully. They pull all the particles out and clean it. The exact temperature depends on the filament you are using to do the pull. Search YouTube, there are loads of how to vids.

RE: Adhesion issues and print quality.

Hi,

The Prusa cold pull process for the mini is described on the following page. https://help.prusa3d.com/en/article/cold-pull-mini_126399. The print results reflect a clean nozzle, especially following several prints. I do a lot of nozzle changes and as such perform the cold-pull cleaning with e-sun cleaning filament. A little bit goes a long way and I consider this filament as an excellent investment.

Regards,

Phil

Stay safe and healthy, Phil

RE: Adhesion issues and print quality.

Thanks. I've seen a couple of videos about cold pull on YouTube now, but I'm away in my bubble. I'll give it a whirl on my return.

Pad

RE: Adhesion issues and print quality.

"I cleaned it prior to the print with PureChem Industrial 99% pure Isopropanol on a kitchen paper towel, and then finished off with water"

Um, why are you using water after the IPA? This will absolutely reduce adhesion.

And for the record, Prusa recommends 90% IPA...not sure if purer is better but that's what the recommend.

RE: Adhesion issues and print quality.

@steve-e3

Good question. Why did I do that?

I guess it was the 1% - I am concerned if it might be oily or leave a residue. Out tap water is very good here, never producing limescale on kettles etc., so I figure it's better than just leaving it possibly at risk.

But now you ask, it doesn't sound too bright.....

It's all a learning experience. Now I'm using glue rather than water, and sometimes that fails also. Very peculiar.

Pad

RE: Adhesion issues and print quality.

I'm printing on themagnetic metal bed that came with the printer. I cleaned it prior to the print with PureChem Industrial 99% pure Isopropanol on a kitchen paper towel, and then finished off with water and a dry rub with the same kitchen towel.

RE: Adhesion issues and print quality.

@oliverthom707

Don't use water after IPA, I am not sure where you get this idea from 🤔 Handbook you received with MNI, chapter 10, has all necessary info and definitely does not mention rubbing water after IPA.

You can use water and dish doap to thoroughly clean surface from grease and gunk (don't use same sponge as for washing dishes), rinse thoroughly, do not touch the surface and let dry. Wipe only with IPA between prints, no water aterwards, nothing else for PLA (PETG and flex is different story, but it's all in handbook). Just IPA alt. denaturated if you can't get IPA, Prusa recommends 90% and above.

If it's smooth sheet, occasionally wipe with acetone if it starts losing adhesion to refresh the surface. Do not use acetone on textured sheet.

RE: Adhesion issues and print quality.

@crawlerin

Thanks for the advice. I'm having a lot less problems with Debonding now, and that's mostly down to poor design leading to part absence of the first layer.

Pad

RE: Adhesion issues and print quality.

Clean bed with dish soap, and first layer calibration is important, for sticking.

If it still fails , use higher extruder temperature, and bed temperature.

If it still fails, use a slower first layer.