3d Benchy layer issues

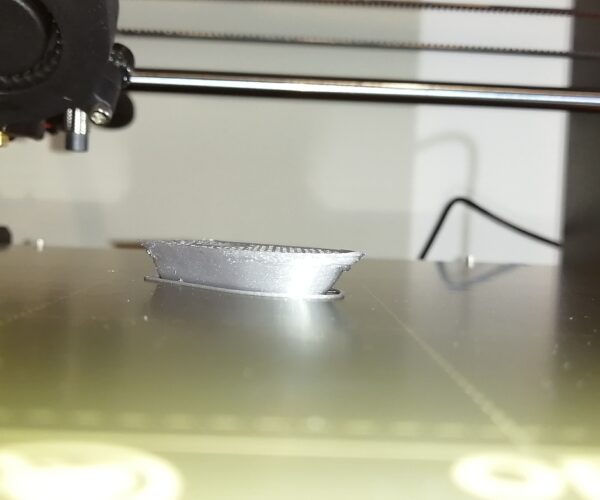

New user. Calibrated with 0.03deg skew and belt tensions are in range. The nozzle sometimes hits the print. Is this a temperature or first layer problem? I've tried loosening the filament tension, recalibraion. The z value is -1.80. Help appreciated, frustrated!

RE: 3d Benchy layer issues

The benchy looks ok. But if your nozzle is hitting your prints, you probably have a first layer adhesion problem. That involves more than calibration. Search here for articles on Live Z My Way (use google of bing - add term "prusa" to your search term). Also belt tension numbers are not belt tension - download and print (only with Prusament PETG) the belt tension gauge for your model printer - that will help you dial in tension much better.

RE: 3d Benchy layer issues

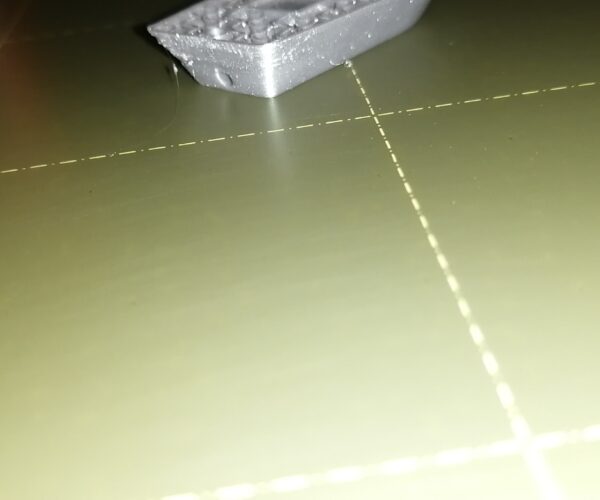

Most people starting out in 3D printing do not know that keeping the print sheet immaculately clean is not optional. A single fingerprint will ruin your longest print. Two fingerprints will ruin everything else. I was among this group.

Soap and water are your friends to make this happen. Keep the alcohol in the bottle, until you know it is required to remove certain residues that build up on the sheet. Why? Alcohol is also very good at spreading fingerprints around and making an invisible barrier that PLA can't penetrate.

===

To the problem at hand: as Dan said, it looks like the Benchy lost adhesion, and the build lifted. This lets the part lift into the nozzle travel path. More often than not the part is knocked loose and you end up with a fur ball of filament. Or worse, a ball of doom.

Lack of adhesion can be oils on the sheet, or a layer one that isn't correctly adjusted. Life Z My way - as Dan pointed out, is a long read, so skip to about page 40 and review Joan's process. fyi, Life Z is a misspelling of Live-Z Adjust.

RE: 3d Benchy layer issues

Noted will print the tension gauges. The nozzle only hits and the high point on the bow and the back. I do clean each time thouroughly with a microfibre clothe and 99% alchohol but will try soap and water.

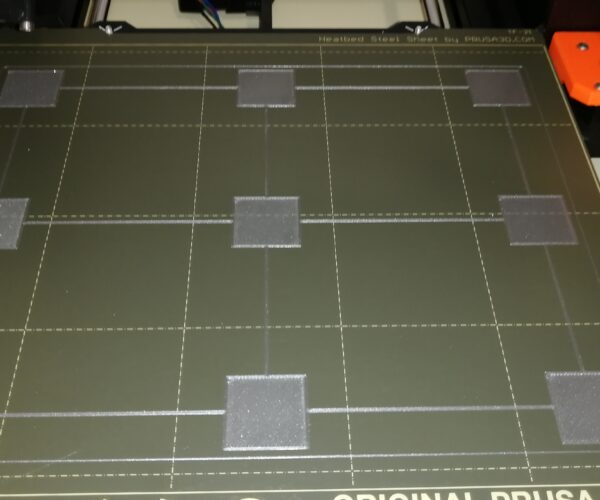

Is it possible there is an issue with my z-axis assembly? Paranoid that I messed something up with assembly although very careful. Attached is my z-axis calibration.

BTW I had no idea this model was so challenging despite being a benchmark. Youtube makes it look like a breeze out of the box. Am I wrong?

RE: 3d Benchy layer issues

was it my post on page 36 that you were referring to Tim?

Don't forget the test files are at the bottom of the first post, on page 1 of the thread!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: 3d Benchy layer issues

@buud

That 9-pad print looks okay to me - probably better than my printer will do right now.

As for clean - that is always relative. A single fingerprint will ruin a print. A build error will usually manifest in other ways - not lifting prints. Common build problems are XYZ cal failures - sticking axis - shifts - hysteresis. You're images aren't showing any of those in any major way.

Try another print of the Benchy gcode. If the nozzle starts to clip the print, pause the print and take a clear photo of the top layer of the print. And another that is zoomed in at the base - looking for the part separating from the bed.

RE: 3d Benchy layer issues

https://help.prusa3d.com/en/article/the-benchy-hull-line_124745/

RE: 3d Benchy layer issues

Benchy is a benchmark because it is difficult to print.

Are you using one of Prusa's gcodes or did you slice this yourself?

RE: 3d Benchy layer issues

@buud

Could you post a pic of your T-Nuts on the Z-Axis lead screw?

Regards

RE: 3d Benchy layer issues

@sink

RE: 3d Benchy layer issues

I don't think there is x-axis slippage due to this print, but you guys judge. Yes default Sd card g-codes only in-print mods were speed @ 60%

RE: 3d Benchy layer issues

For some reason I can't see your last picture, but I think it looks like a heat related problem. See for example the bridging of the window. Something like lack of cooling or too high extrusion temperature. Never had similar problems though, so I might be completely wrong.