Y axis Shift

Ok, so I have never seen this before.

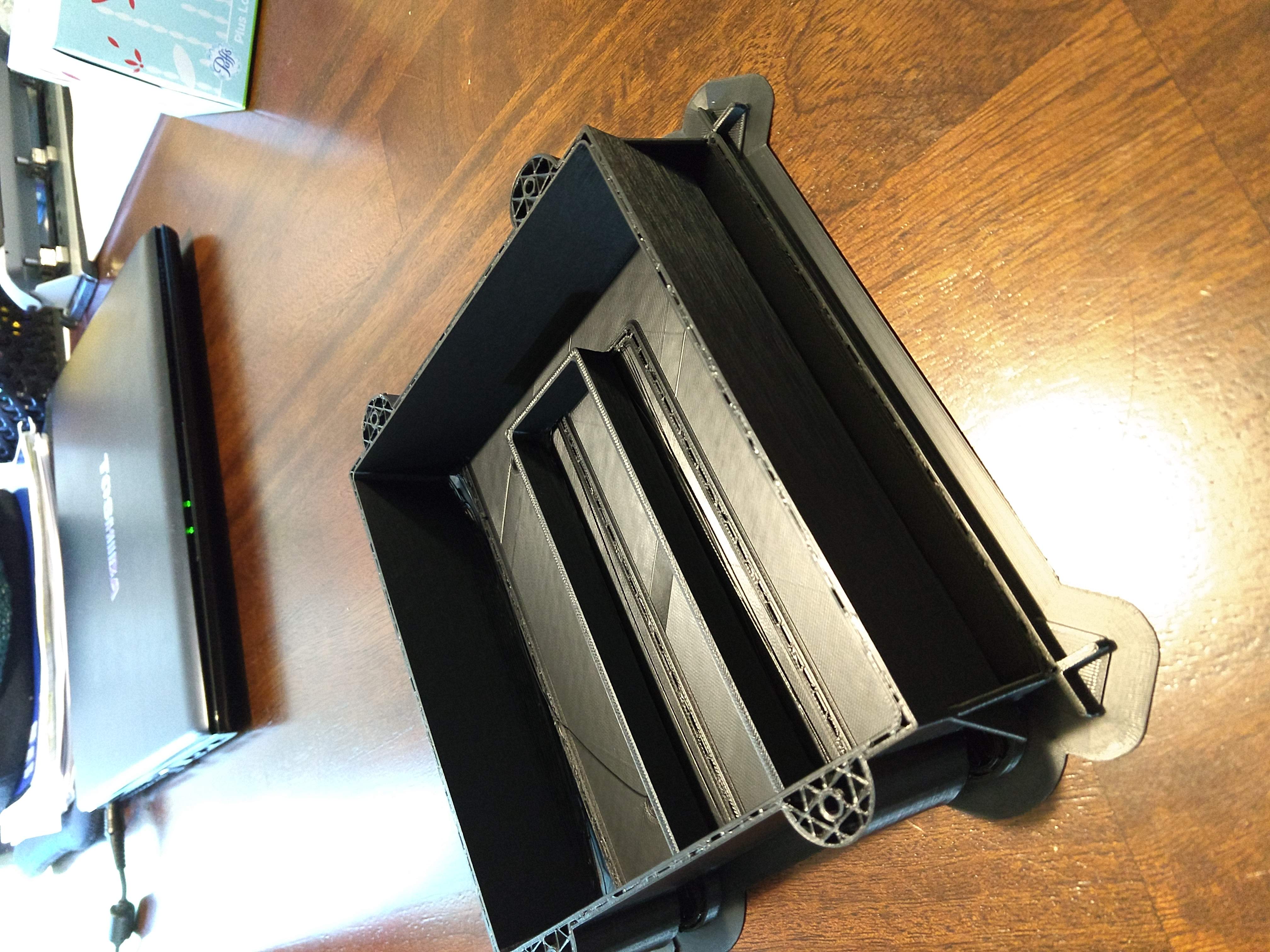

I am printing a 2 5S LiPo battery enclosure. I have already printed this once just fine. I have never seen anything like this. About 20 something layers in the whole print shifts back about 100mm and continues printing perfect. ??? What???

All the belts are tight, I don't see anything that the bed is touching, or anything that might be loose... hmmm. I don't see any impact on the print, or print head.

Any ideas, or thoughts would be helpful - Thanks.

Re: Y axis Shift

Ok, Well I took a stab at a guess, and oiled the Y axis rails... I thought - Maybe one of the linear bearings got jammed, then the belt skipped...

Then I re-sliced the stl, and started another 16hr print. When I get up in the morning - It did the same thing... In the exact same spot. I am guessing now that it is the gcode that is messed up some how. I will try to examine it (the gcode), but am not sure exactly what I am looking for...

Any help would be appreciated.

Thanks

(SOLVED) Y axis Shift

Wellp - I fixed it.

Prusa has a help page ( https://help.prusa3d.com/l/en/article/qiPUfukPVw-layer-shifting ) that does address some issues on this topic.

I tried printing this in Auto Mode, Silent, and High Power Mode. I am not sure what all the differences are, but they all resulted in the huge shift as seen in the images above.

So, before I went turning my machine over and screwing up all my calibrations, I ordered some new GT2 belt from Amazon.

When it arrived, I flipped my machine over and followed the manual instructions ( https://manual.prusa3d.com/c/English_manuals ) backwards to remove the original belts. Then I reinstalled new belt as per the manual. The belts that I put on were much tighter than the ones I removed. I plucked them and tried to make them as reasonably tight as I could without over-tightening (low guitar string sound, I would say mine sound like an acoustic 'G' sound, lol) I also oiled (Superlube) all the rails real good, and the lower idler bearing (couldn't get to the X axis bearing, but it spins nice and free)...

Now it's morning, and the print has been going for 10.5 hrs, and it looks fantastic. The previous 4 failed(shifted) prints usually failed in the same spot around layer 25.

NOTE: This is a very large print that uses the majority of the bed. I used Slic3r with stock Prusa settings to create the G-Code - AND... This print prints so so so oddly. I have never seen a print where the print head dances all over the print so much - It doesn't make logical sense when watching it. It makes some pretty darty moves when printing. I was going to try another slicer software, but after trying to set up Cura, I noticed that the settings for i3 Mk2 were way different than the Slic3r settings (like head temp, and bed temp... And, I didn't really want to fine tune and debug slicer settings when already dealing with an issue.

So, in Summary - It was the loose Y-Axis Belt. This print also suffered from a bad Slicer G-Code pattern, and I wish I was more familiar with other slicer software that could make a better G-Code pattern...

Re: Y axis Shift

(UPDATE)

So, I had an issue again yesterday with printing the lid to this battery holder. The X and a little Y shift. I read some more forums and bolgs on the topic, and nothing really hit home as to what is causing this issue.

The Fact is:

This is a really large print, and the print head makes some pretty drastic moves with the way Slic3r sliced the stl file.

Some good thoughts that I read that could be causing this issue that are undetermined at this point:

- Heat build up in the stepper motors causing failure.

- Loose wire for stepper motor.

- Bad Serial connection (or intermittent) from OctoPi.

- Not enough power to Stepper Motor (Silent Mode).

- Too much power causing heat (High Power Mode).

- Speed of non Print moves, or Acceleration.

- X (and or Y) axis moving fast enough on a large print to make contact with the limit switch (causing loss of position).

I addressed a few of these to create a successful print. Here is what I did:

- I put the i3 Mk2s into High power mode.

- I did not print in the enclosure (PETG) - To allow for cooler steppers.

- I adjusted the default Prusa PET Settings to lower "Tavel" speed to 130 (not 180) for non print moves.

- I lowered the "Acceleration control" - "Infill" to 1000 (not 2000). This is because the axis shift was always somewhere right around finishing inner infill.

- I made sure the USB to OctoPi was secure, and rerouted the cable a little to keep it out of contact with other cables.

That was it, I had a perfect print this morning. I am guessing that this very large, horribly sliced print (that has some wild moves) somehow skips or looses position because of the speed and distance of some of the moves. (Not sure that all made sense or not).

I am guessing that putting the printer in High Power Mode, and Slowing down the "Travel. and Acceleration" were the help that I needed. I probably should have tried printing from an SD card, but I couldn't find one , and I figured, that would be the next step...

Re: Y axis Shift

I have an MK3 and MK2.5 that both print side by side in the same environment. Every once in a while my MK2s use to have problems with shifting layers in the x-axis. I could never figure out why, but I recently converted my MK2 to an MK2.5 and I made sure all belts and screws were tight, all rods and bearings oiled and running smooth, all wires in good share, and now I'm once again noticing that for many of the longer prints (>4 hours) I sometimes get an x-axis or y-layer shift. It wasn't confined to just one axis 🙁

This last week I was trying an object in PETG and I couldn't get it to finish without shifting layers along the x axis. I had tried slowing down the print speed to 50% and it still had the problem. After 3 failures, I was thinking that since we have been having pretty hot weather, I took a small house fan and aimed it at the printer blowing at a low speed. Yeah! No problem with the print. But how do I fix the problem without having to point a fan at my MK2.5?

I saw this post and it mentioned not enough power to the stepper motors and I read on another forum that when the drivers heat up that the steppers don't get enough power and can fail. Their solution was to replace the drivers or try increasing the current to the drivers.

Does anyone have any information on what type of servicing I should do on my MK2.5? How would I try to adjust the current and is it safe? Are the drivers something easy to replace and how would I test if they are bad?

Any help on what to do or pointing me in a direction for help would be greatly appreciated.

Re: Y axis Shift

I too had a major layer shift on the Y axis. I then tried to print that same object but with the long side on the X axis. I did not print too well but there was NO layer shift!! What would be causing the layer shift by just reorienting the object 90 degrees?

Jim

Re: Y axis Shift

My MK3 and MK2.5 sit in the same enclosure. I never had a shifting problem with my MK3, but I did with my MK2.5. Based on what I read about over heating drivers, I decided to just buy a bag of small stick on heat sinks and applied them to all the driver chips for the stepper motors. I haven't have a problem since. Tightening, oiling, ... didn't help the problem.