Uneven heat bed temperatures

Hey guys,

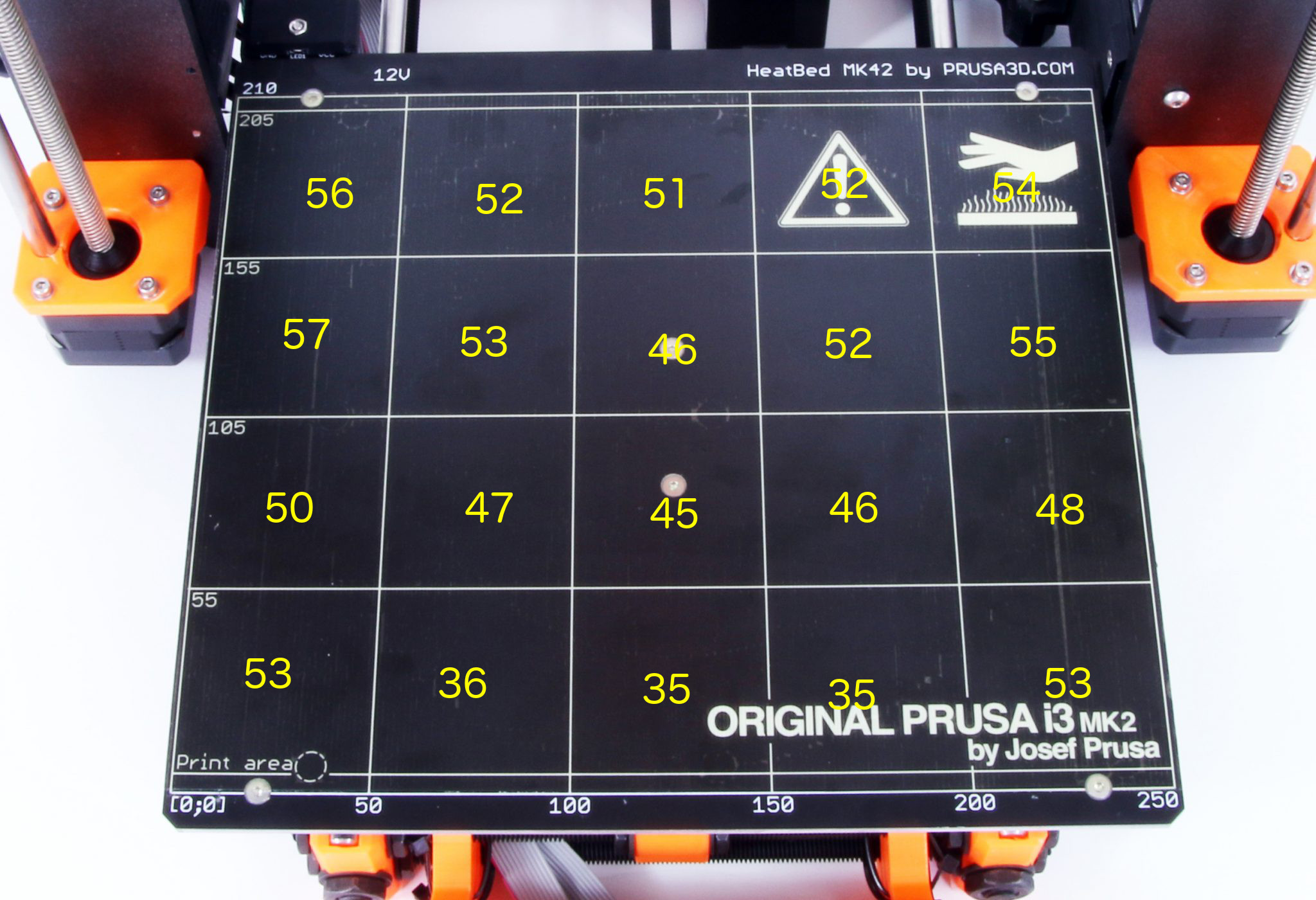

I'm quite new into 3D printing, just get the Prusa i3 MK2 in the end of October. So far I'm really satisfied with it, printed lots of stuff, small or big. But, I tried to print the bundled RC Spitfire model and get some bad warping at the ends of some parts. At home we have some simple tool to measure temperature, so I did some scans of the hotbed. I found that in the bottom central part, temperature is around 20 degrees (celsius) lower than the other parts of the bed. Specifically when I preheated bed for the PLA, most of it is around 55 degrees, but in bottom central part (the one which is most closer to lcd), I'm measuring only 35 degrees. I observed this for multiple times, started to check it after I got first warping on the spitfire parts. All the mentioned warping (mostly wing parts) occurred in that lower central part of the bed, other side of wings were ok. I actually tried to raise the temperature to 70 degrees, and the result was better, but there was still some warping.

I attached stock image of the bed with the temperature distribution which I measured with the tool (I was sure to aim with the thermal measuring part, so it should be accurate). Values moved a bit during measurement, but not more than few degrees.

I guess this is not normal, right? I had just few small warping problems before, but it was probably because I didn't print really big parts, or the parts had base which was probably more resistant to warping (hull parts of spitfire were not really affected with this). I would expect that sides should have all similar temperature, bottom, top, left or right, but the bottom part is considerably colder.

Printer was moved few times (took it to some exhibitions) and actually today I found that one cable from the bed break (heating one, not the sensor), probably because it was pushed during the moving. This was an easy repair and probably should't affect the temperatures (I measured the same results before and after the repair), but mentioning it just in case.

Re: Uneven heat bed temperatures

The temperature variation on my bed are not that large.

Where was the extruder when you heated the bed?

I have modified the 'Custom G Code' in Prusa Slic3r (in Printer Settings) so that the extruder gets parked at the top at the end of every successful print.

G4 ; wait

M104 S0 ; turn off temperature

M140 S0 ; turn off heatbed

M107 ; turn off fan

G1 X100 Y200 Z200; in order to move X axis off centre and lift extruder for cleaning

M84 ; disable motors

Keeping the extruder far from the bed has multiple advantages, including that it is then less affected by the heat of the print bed and less 'live z-adjust' may be needed, and that the considerable draft caused by the heat sink cooling fan does not cool down one part of the bed more than another.

Re: Uneven heat bed temperatures

Hi, thanks for reply. Actually I measured the bed temperature multiple times, during prints or just during preheating, when temperature on lcd shows targeted 55 (for PLA). I know what you mean, I'm often moving the extruder up after print, so I can cut the leftover filament from the print head. But as I learned its not really needed, printing on this printer is literally plug and play so far 🙂 just remove print leftovers from bed and start another print

I think print fan can influence the temperature a bit, I tried to measure the surface temperature during some prints of multiple, almost flat objects, and of course on parts to which the fan blows for a while, they were colder, like 5 degrees or less. But I doubt its my case, as I can measure the uneven temperatures during prints or just when the heatbed is heated. Data above were measured after printer was preheated for PLA, print fan was inactive (as it should be in that scenario) and extruder was resting to the left and quite up, so it wasn't and obstacle during measurement of temperatures.

Re: Uneven heat bed temperatures

The printbed is simply a PCB and the copper tracks do vary in both width an thickness due to manufacturing tolerances.

It is also designed such that the four corners are hotter than the rest of the bed, so a variance across the bed is to be expected. And, of course, there is only one thermistor, on the underside near to the centre of the bed.

However, that does not explain the really low temps at the front, but if you are not having any issues then there really is nothing to worry about.

Personally, when printing PLA, I set the bed temp to 60 degrees and 65 for larger prints as I find those temps are more reliable for my bed.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Uneven heat bed temperatures

Hi Peter,

I wouldn't bother anyway, as I already printed lots of stuff and usually the result is really good. I just happen to run to this issue when I'm printing something larger, where part of the print is in this colder area. In that case often the part of print there separates from the bed and warps a bit. This is mostly problematic with mentioned spitfire print, when printing wings, as you have to glue them together. Even when I set up the printbed temperature to 70 degress celsius, I got the warping, but description for the model mentions that I shouldn't get any. So it is a bit of an issue 🙁

I'm using gcodes bundled with the newest drivers. Part of the print (back of the fuselage and one wing) was done with silver PLA which was open for about one month, rest of the print with brand new, previously unopened silver PLA filament, wings parts warped in both cases (and mostly on the part with lower temperatues)

Re: Uneven heat bed temperatures

I'm also seeing something like this, but it is a problem because i think it's causing my ABS prints to lift.

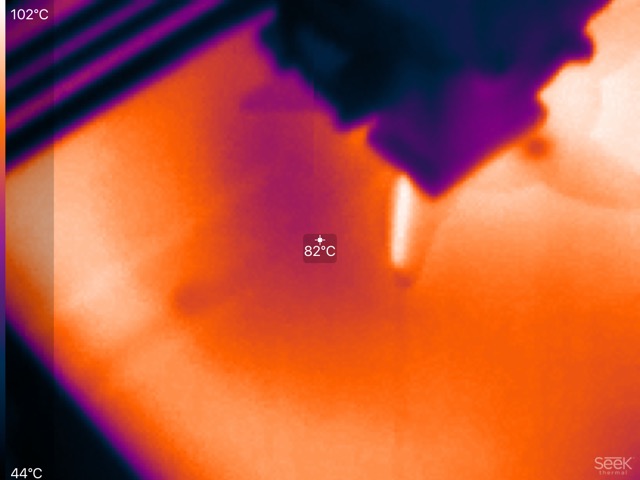

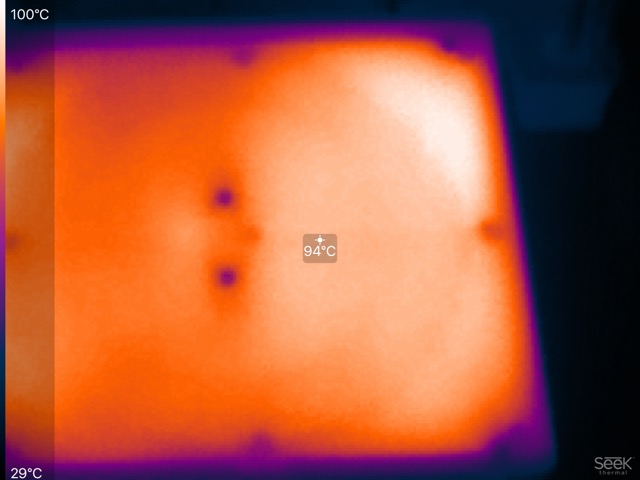

I'm seeing temperature differences of ~5C in the center when the bed is heated up and the extruder is at the top of the frame.

While 5C isn't a lot, the problem is that once the printer starts printing, the difference can rise to 20C:

The print starts lifting pretty quickly on the left where the temperature is closer to 80 than 100C, which is the bed target temp.

Re: Uneven heat bed temperatures

Sigh, and now because of this my bed has bubbles/blisters.

The ABS tried to pull up on the colder side and took the PEI with it. There are now a couple blisters on the colder side :/

Do the beds always have a warm and cold side like this?

Re: Uneven heat bed temperatures

The bubbles will disappear after a few heating cycles.

Not sure how much your situation is normal, I don't have an infrared camera to test, and I don't print ABS.

- Gab

Re: Uneven heat bed temperatures

Did you ever resolve this? I just, after about a month of usage, started getting pretty much constant print failures. It has turned out that something seems to have failed and the middle of my bed is 10-15 degrees low, so nothing is sticking. I see a 20-25 degree variance across the print surface during printing! This was after a month of no failures, so this isn't a manufacturing tolerance problem... something has changed.

I can successfully print if I slice models avoiding the middle, but with a 55 degree bed, I'm seeing spots in the mid 60's and the low 40s, so its like playing roulette if I get good adhesion.

I'm trying to find a solution because other than tiny knick-knacks, I can't print much anymore.

Re: Uneven heat bed temperatures

as the heated bed is made up of a pcb is it possible that the tracks are becoming delaminated in certain areas?

would it be possible to try a 3mm thick aluminium plate placed on the track side of the heated bed to stabilise the heat.

over the top of the aluminium plate you can place kapton tape or a glass plate.

insulating the underneath of the heated bed will enable most of the heat to be fed into the aluminium plate. try a cork tile.

this should stabilise the tempartures over the whole area.

if this doen't you should be looking for draughts, try shielding the outer of the printer with cardboard to prevent air movement.

the ultimate would be to use a proper heated bed made up of a fep (kapton) heater attached to a metal plate, the only problem with this is the increased weight of the movable plate. it may cause a certain amount of backlash when printing fast. so you may need to slow your printer down.

i may be experimenting with this in the near future.

helping others with 3d printer problems

building 3d printers

showing you can repair almost anything with a 3d printer and innovation - well, design!!

www.best3dprinter.stan-tech.com

Re: Uneven heat bed temperatures

I don't have any means of measuring this, but just based on feel I've noticed that I'm getting a very similar temperature distribution to OP. Is there any means of recourse on this?

Re: Uneven heat bed temperatures

It's not like the cold parts of the bed can't get any hotter - when I turn up the heat, they get warmer as well, but they never quite reach the target temperature...Could it be a thermistor problem?