Tree frog under extrusion problem

Hi,

I finished building the MK2 kit last Sunday and I started printing the sample objects on the SD card to test the printer.

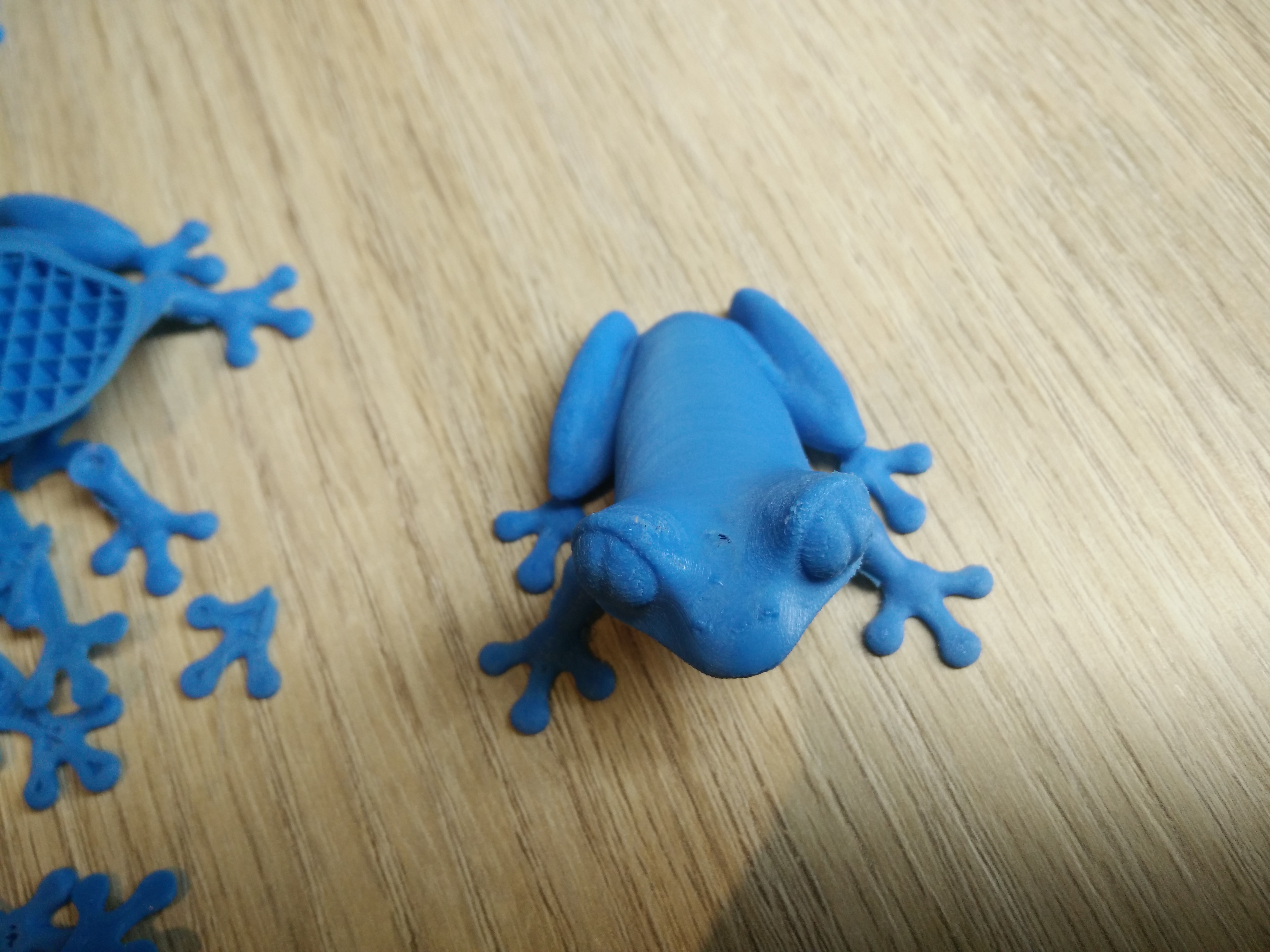

After some tests I'm having problems with the tree frog (50 microns) from the SD. It looks ugly, like with an under extrusion problem. So I started to test the same object but with different parameters to find the problem. Always using the PRUSA PLA from the kit.

Actual tests: (Always with the sd card bundled file)

* More temp: 220ºC and 200ºC instead of 210ºC

* More flow rate: 110% instead of 100%.

* High power vs silent mode

* Without printer fan.

All of them with almost the same result, a hole at the top part of the head of the frog and some parts with an ugly looking.

Trying to find how to fix the problem I found some related posts at the forum with similar results but without a solution. http://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/problems-while-printing-50-microns-t1206.html

Since I run out of ideas about how to fix it I checked if the printer is extruding the right amount of plastic (The idea came from this post: http://prusaprinters.org/forums/topic/under-extrusion-issues/ )

I make a mark of 100 mm in the filament and extruded 100mm using the move axis option at the printer. it only extruded 93.5mm instead of 100mm. I checked it twice, once in silent mode and once at high power.

I checked the extruder pulley and it looks good and well tight and the extruders springs are also correct (length of 13 mm when tightened).

I don't know what else can I check. Any ideas? 🙄

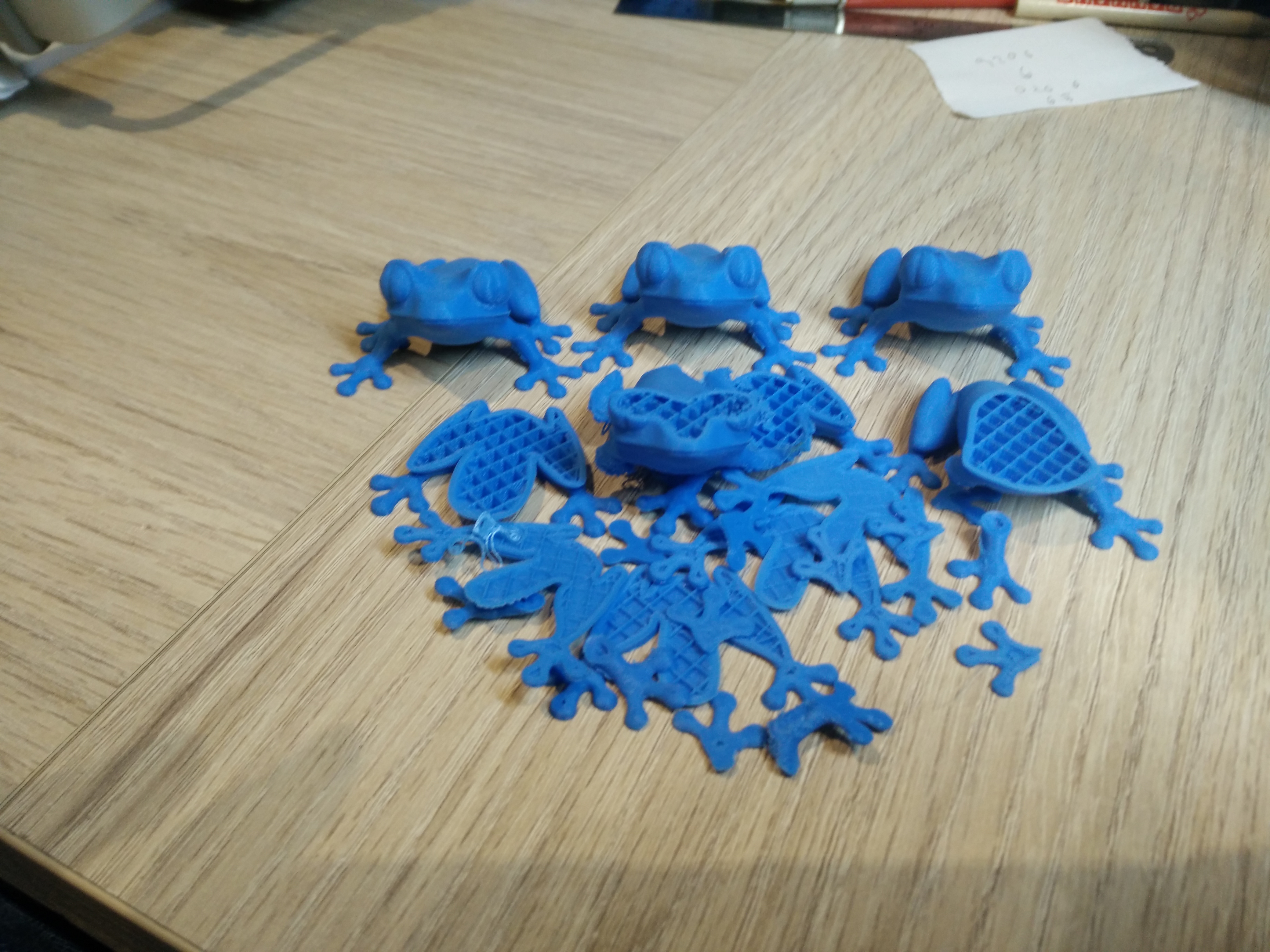

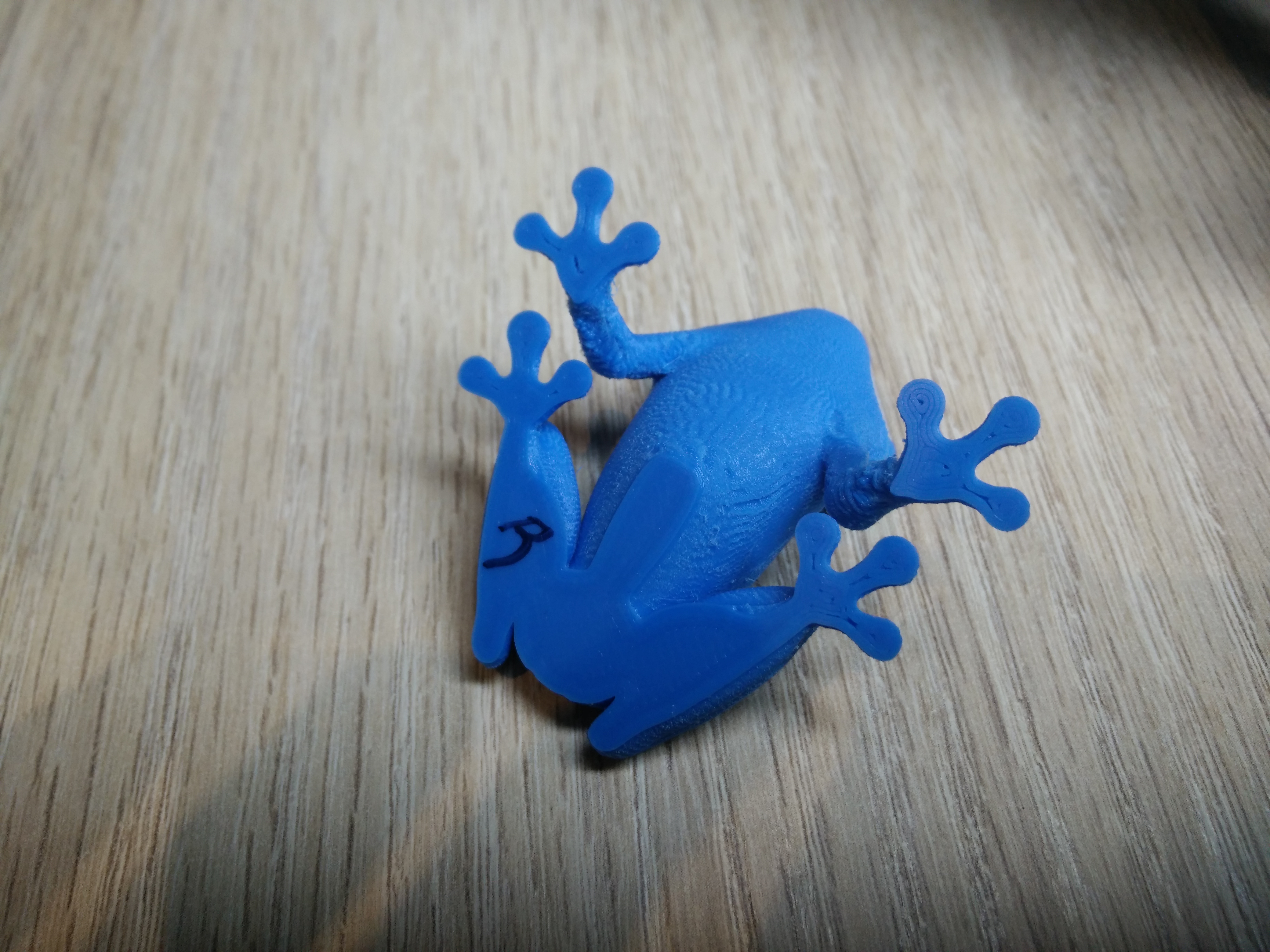

I attach some pictures with some of the tree frogs. I stopped the print at some of them after find the problem persists.

Thanks!

Re: Tree frog under extrusion problem

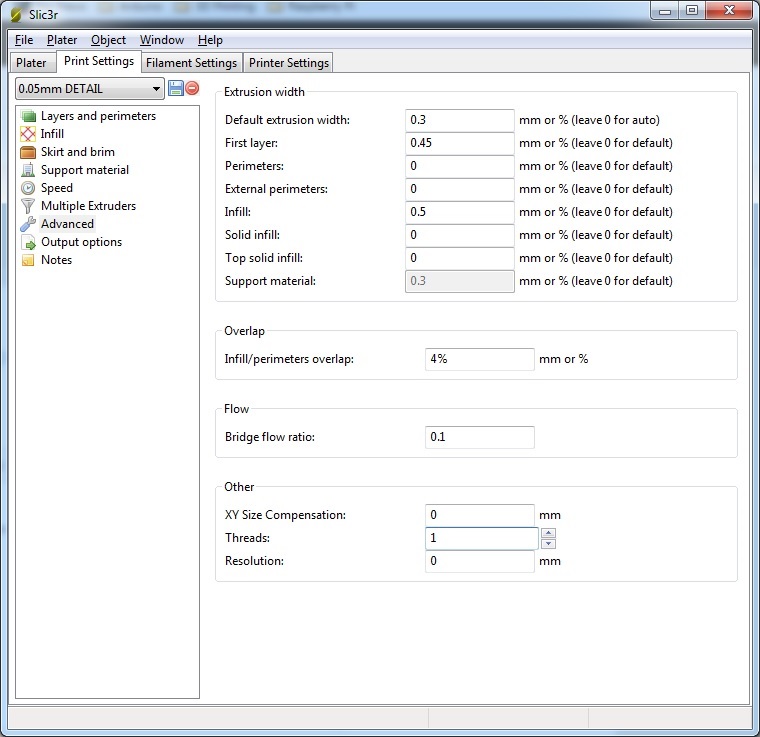

Not sure if this is your problem, but I was not able to print a good tree frog at 0.05mm layer height until I "fixed" the Slic3r print settings on the advanced page. The default 0.05 settings were radically different than the 0.1 and 0.2 settings. I adjusted the 0.05 to be like the 0.1 settings and my tree frog problems were solved.

Kevin

Re: Tree frog under extrusion problem

Hi Kevin.

Thank you for the info. I'm going to try it but I think that the TreeFrog gcode coming with the SD card at the kit should work out of the box, if not, something is wrong.

Re: Tree frog under extrusion problem

I make a mark of 100 mm in the filament and extruded 100mm using the move axis option at the printer. it only extruded 93.5mm instead of 100mm. I checked it twice, once in silent mode and once at high power.

I checked the extruder pulley and it looks good and well tight and the extruders springs are also correct (length of 13 mm when tightened).

Miguel, this is a great test that I didn't even think of!

I have the same problem with the frog when printing 50um and I had just about given up on printing at that resolution.

I am certainly curious to see why it only extruded 93.5mm instead of 100mm, and I am curious if others do the same test what their results are.

Re: Tree frog under extrusion problem

I'm not sure when the SD card version you have was sliced. The one that came with the 3.0.8 firmware does not print correctly (for me). The one that came with my kit (3.0.6 or 3.0.5 ... I don't remember) prints fine. Until I fixed the Print Settings Advanced page settings, every steep overhang model I sliced with Slic3r (like the tree frog) printed poorly at a 0.05mm layer height. Hopefully it will work for you as well.

Kevin

Re: Tree frog under extrusion problem

Another day, another frog!

I'm focus in trying to understand the under extrusion problem calibrating the extruder steps because I think it's the root of the problem.

After some more tests with the Pronterface extruding 100mm of filament and measuring the extruded filament distance I found that the extruded distance is not consistent when changing the feed rate of the G1 command.

Sending: (Always using 5 samples at lease to assure that the result is valid)

G1 E100 F50 -> the unextruded distance is always near 5 mm

G1 E100 F100 -> near 6 mm

G1 E100 F200 -> near 7,5 mm

I was thinking that if the distance is always the same I can change the steps per mm of the extruder with the M92 command. But since is not consistent I don't know what can I do. I think I build something wrong but I don't know what.

Any ideas?

@Kevin I found that the version 1.7.0 of the drivers have a different version of the TreeFrog gcode, I'm going to try to print that version tomorrow to check if works better.

Thanks!

Re: Tree frog under extrusion problem

Miquel

So if I understand correctly, the greater the feed rate, the greater the under-extrusion.

I wonder if that is due to default acceleration settings... Before you test, can you send

M201 E600

Which sets the acceleration to 600mm/s^2 and is significantly less than the firmware default.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Tree frog under extrusion problem

Checked again sending the M201 command before the tests:

SENDING:M503

echo:Steps per unit:

echo: M92 X100.00 Y100.00 Z400.00 E161.30

echo:Maximum feedrates (mm/s):

echo: M203 X500.00 Y500.00 Z12.00 E120.00

echo:Maximum Acceleration (mm/s2):

echo: M201 X9000 Y9000 Z500 E600

...

Same results than before, I also checked with G1 E100 F300 and its even worse, under-extruded 11 mm (sending 100 mm).

thanks!

Re: Tree frog under extrusion problem

Miquel,

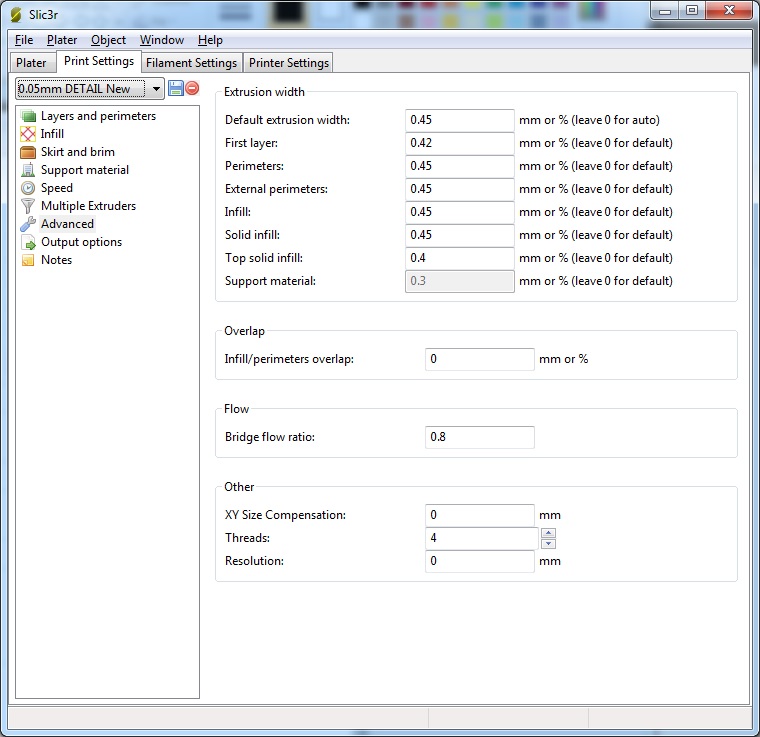

How are your 0.05 Advanced Print Settings configured? Below are my before and after settings.

Before:

After:

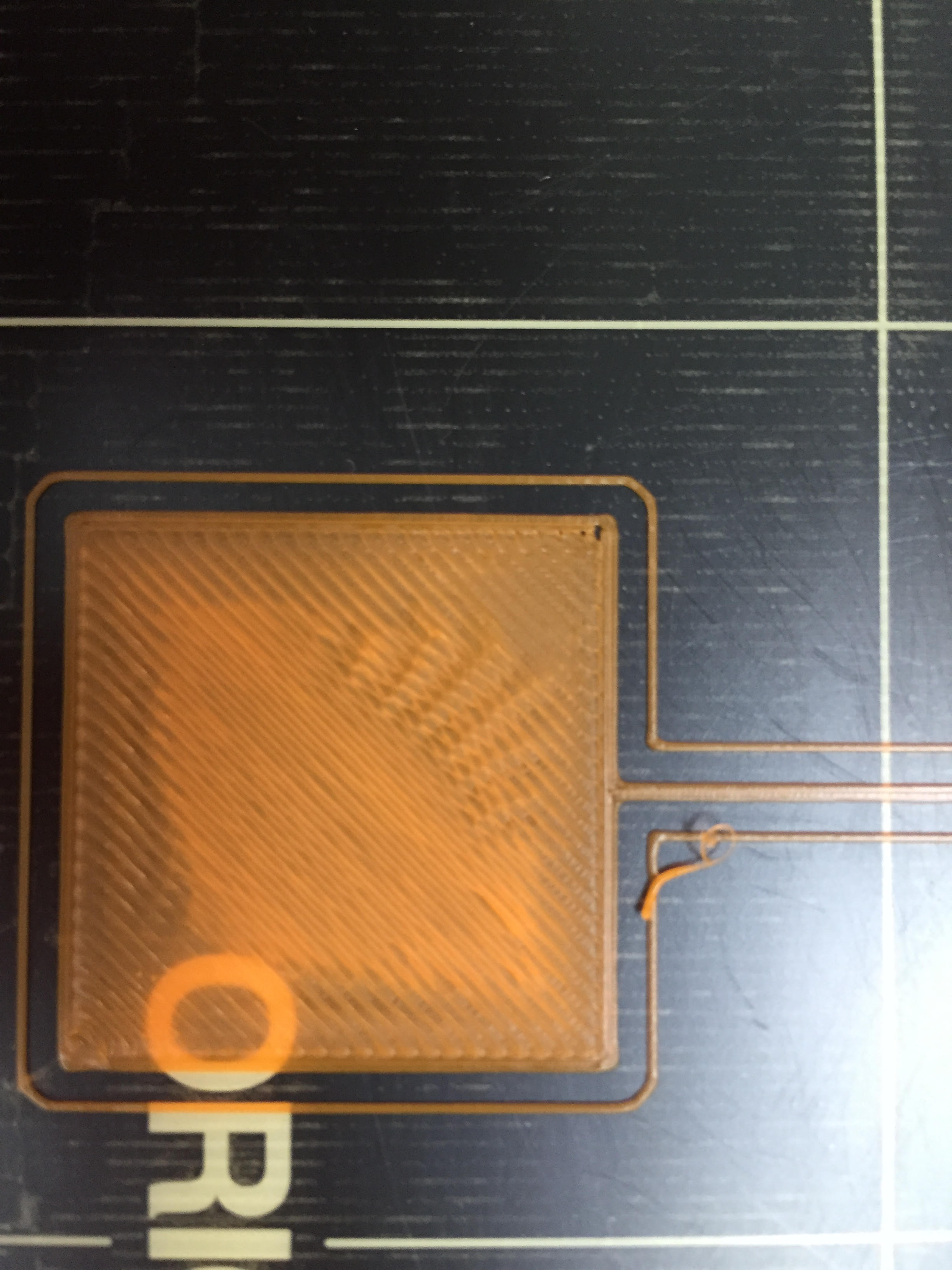

My test frogs. The two on the left were printed using the the Before settings. The one on the right was printed with the After settings.

Top:

Re: Tree frog under extrusion problem

Hi!

Since the under-extrusion problem seems related to the inconsistent extrusion I have two hypothesis:

1) The extruder motor is working fine and the problem is on the pulley or the filament is sliding off the pulley.

2) The motor is not rotating the same angle an it's related to the spinning speed since the Feed rate means more or less speed, (loosing steps or not working fine)

Does it makes sense?

Any ideas about how to test it?

Thanks!