Top infill problem

Hi all guys,

I print some object for my models...and i try to play with slic3r setting,but i still have a problem.

In some part,my top (and flat) surface have a Zig-Zag finish,the surface was not smooth,and i can see the extruded line.

I try to increase the infill overlap (to 35%),i try to increase the flow,to lower the speed....but nothing seems to work.

I add a photo for explain (it have 1 hand of Tamya primer spry)

Thank you

From Florence with Rage!!!!!

Re: Top infill problem

Hi Daniele, have you tried more top layers?

sometimes top layer issues, start because the lower layers have insufficient support.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Top infill problem

Hi Joan,yes i try with more layer,this have 15 top layer....maybe i try to increase it?

From Florence with Rage!!!!!

Re: Top infill problem

Hi Daniele, 15 top layers should be enough...

can you put the STL in a zip file and post it here? maybe someone can try printing it at their end...

I am going out soon. but could probably print tomorrow night if it will help!

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Top infill problem

sure,

that's would be amazing.

for knowledge,i slice it using Slic3r prusa edition,Prusa Pla filament (extrusion multiplier set to 1,025), 0.05 Detail with 0.25mm nozzle.

thank

From Florence with Rage!!!!!

Re: Top infill problem

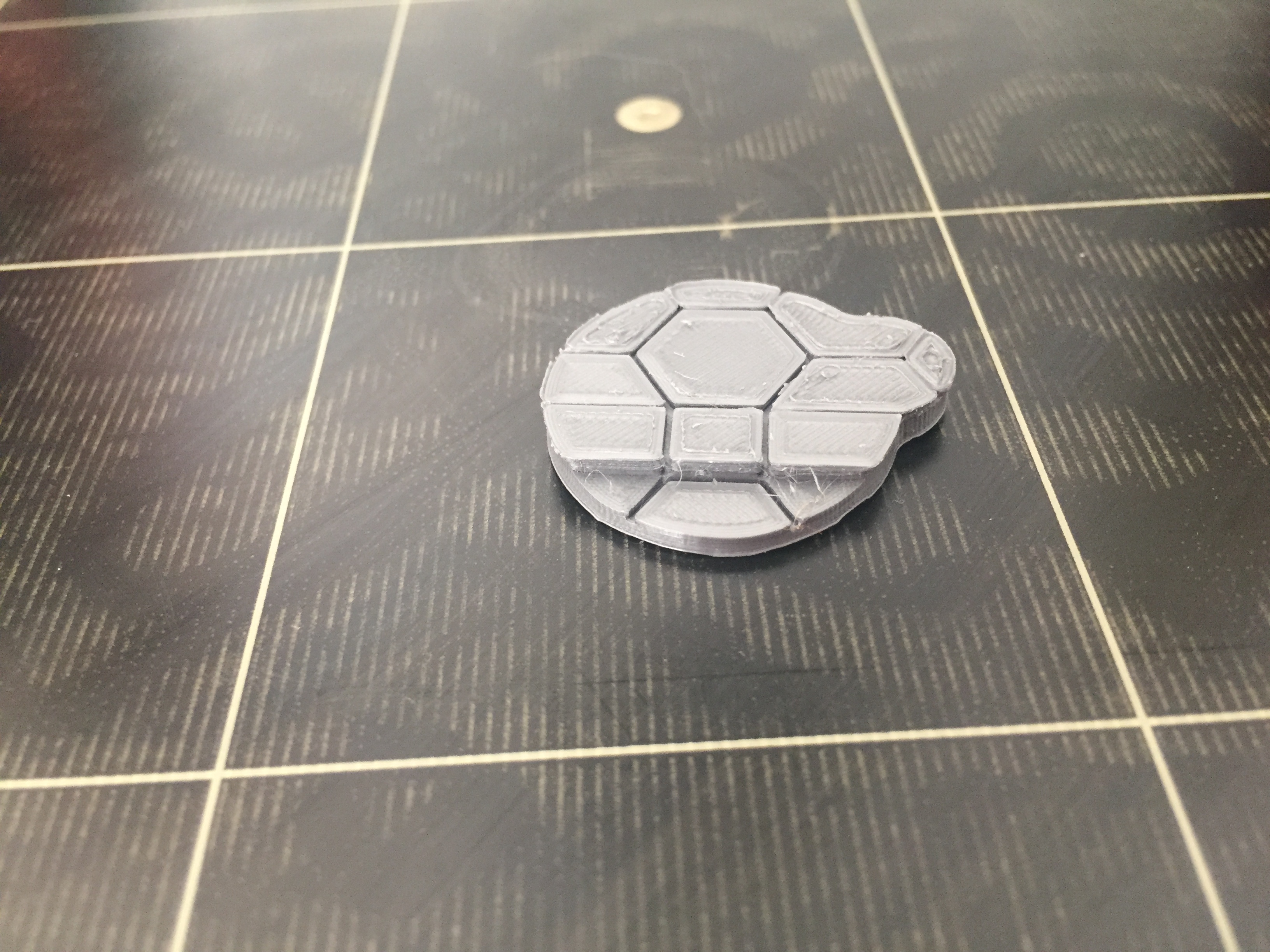

Oooook,i have some news....i update my printer today,i cut off the Zip from Y axis and i use a printed ABS housing for linear bearing,re calibrate allthing,re sliced the file using 50% overlap,top infill speed to 15 mm/s,15 top layer and 10 bottom layer.

Well......the surface now is fine,a little bit overextruded in truth....and there is one part where the escape beetwin the tile wasn't correctly printed (right side of the photo).

But the great issue now is that my print is warping from the bed,i try to set an higher temp (from 50 to 55°),lower the speed but nothhing,still warping....any idea? (Also to increase the surface smoothnes and to lower the oozing)

Ps: i never had warping problem on this model before

From Florence with Rage!!!!!

Re: Top infill problem

Here are some test prints

all printed 0.4 nozzle because I dont have a smaller nozzle available at the moment in Cheap Chinese PLA

the left hand print is Prusa Slic3r 0.15 Optimal settings bed 55 extruder 215 I think.

the middle is Prusa Slic3r 0.05 detail standard settings and it warped off the bed...bed 55 extruder 215

the right is Prusa Slic3r 0.05 detail, with a bed temp of 65 and extruder 200

all other settings standard.

personally I think the 0.15 version on the left is best...

might have been even better if I had changed the bed temp and extruder temp...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK