Thermal Runaway with 3.0.6?

So over the past two days or so I've been getting a "Thermal Runaway" error with my prebuilt printer a bunch (just when I thought it was working perfectly otherwise 😯 ). It was a few times in a row with the same model (215 first layer, 205 second layer) where it would get to the second or third layer and then give an error and cut off the heat, so I thought it was something in the slicing that went wrong. So I tried the vase gcode off the SD card, and it appears to have printed the entire thing, but still shows that error on the screen.

Weirdly, I've been monitoring the temperature during these errors and it seems to be consistently staying at its set point. So I'm wondering if there's any possibility that it's a bug in the firmware, or if anyone else is seeing the same error message. I won't have time tonight, but at some point tomorrow I plan on flashing an older firmware to see if I get the error still.

Re: Thermal Runaway with 3.0.6?

I had this problem as well. I replaced the thermistor and it seemed to go away. I'm not sure what is happening--I wonder if somehow the thermistor wires are ever so close to touching and the angle of the head causes them to touch? Or perhaps they are shorted against the heater block under the retaining washer? Or perhaps the wire sheathing got cut during assembly and the print head at a certain point causes wires to short? I dunno. I'm befuddled--I don't like non-determinism!

Re: Thermal Runaway with 3.0.6?

So as it turns out, as soon as the cooling fan comes on, the temperature starts to drop... which is why it only is starting on the second layer... on both 3.0.6 and 3.0.3.

So I'm assuming this is probably some sort of hardware failure, I don't know.

Re: Thermal Runaway with 3.0.6?

We are filling a knowledge base. Here is an entry on the Thermal Runaway problem. Did it help?

http://help.prusa3d.com/mk2-electronics/thermal-runaway-and-temperature-drops

Vojtech

Re: Thermal Runaway with 3.0.6?

I've had the same problem with 3.0.3 and 3.0.6.

If I dial the fan speed back to 100, the hotend will retain its temp setting, but as soon as the gcode turns up the fan speed again the temp plummets.

The referral to the knowledgebase is good, but it doesn't really give good diagnostics and actions based on the diagnostics.

Regarding the thermistor, it might be useful to point to the assembly directions on e3d-online for installing the thermistor. Following those directions, I put my thermistor all the way into the well, then bent the leads over the edges, held them in place, and tightened the screw. If the screw were too tight, would that cause the runaway condition? Does the thermistor function if it is _anywhere_ within the well? Or must it be all the way into the well? I don't yet have a sense for how sensitive things are.

Regarding the heater: there was another thread here wherein PJR talked about testing the resistance of the heater wires, the voltage at the power block, and computing the wattage of the heater. Those instructions might be useful to include on the knowledgebase.

And finally, regarding the fan: How high is too high? I'm using the default Prusa MK2 profile in Slic3r--in other words, I'm not intentionally setting the fan speed. In tuning, it shows a speed of 216 for much of the print, although I did see a 250 last night. As well, you say the heaters should handle 100% fan speeds. t would be helpful if there were a gcode test that could exercise the fan, turning the nozzle temp up, turning the fan on 100%, let it drop, then repeat a number of times (taking into consideration the hysteresis?) to see if you could reproduce the thermal runaway. As of yet, I know nothing about gcode so I'm the wrong person to contribute but perhaps soon.

At Josef's suggestion, I'm reprinting the fan shroud. It appears that on github there was a redesign that might be post-initial launch? Not entirely sure. It would be cool if this knowledgebase had a link to the fan part and some instructions on printing it (i.e. ABS only, 20% infill, etc.)

Re: Thermal Runaway with 3.0.6?

Curtis

You may have seen the test results from my printer here: http://shop.prusa3d.com/forum/original-prusa-i3-mk2-f23/too-cool--t1252-s10.html#p9891

I don't think this is a common problem and it is very difficult to Prusa Research to rectify if they cannot replicate the situation.

In my mind, there must be a particular set of circumstances causing this and I don't have a clue what those circumstances are, but it quite likely has something to do with the heater cartridge, cabling and/or RAMBo connector. There may also be an issue with the direction of the airflow from the part fan and also maybe the assembly of the extruder. But this is guessing.

This problem occurred with the Mk1 - there were several issues combined to cause the problem most of which have been rectified with the Mk2. It was worked around by Prusa Research by shipping out a 40W heater cartridge with later printers as the actual causes could not all be fixed with the Mk1 design.

It would also appear that E3D have addressed their end by redesigning the V6.

Really sorry I can't be more help, but for the time being, it seems that your only option is to turn the fan down in the slicer.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Thermal Runaway with 3.0.6?

Peter,

I did see your post and haven't been able to get my octoprint setup to replicate your diagnostic.

I created a diagnostic test that will cause a thermal runaway every single time on my printer. I print a simple skirt, set the fan speed to 100%, then increase the nozzle temp and wait (M109 S220). With the fans @ 100%, the nozzle temp plummets--it never reaches the new temperature, and ends in thermal runaway. I have attached both the gcode and STL file, but here is the relevant subset:

---

M106 S255 ; enable fan at full speed

M109 S220 ; set extruder temp up and wait for new extruder temp to be reached-Watch LCD: does it climb?

; if it doesn’t climb, you should get a thermal runaway by this point

; if it does climb, let’s try it again by dropping temp, turning on fan, and raising temp again.

M107 ; turn off fan

M109 S210 ; set extruder temp down 10C and wait for extruder temp

M106 S255 ; enable fan at full speed

M109 S215 ; Set extruder temp up and wait for new extruder temp to be reached-Watch LCD: does it climb?

; if it doesn’t climb, you should get a thermal runaway by this point

; if it climbs in both tests, either there is no thermal runaway or this test isn’t effective.

M107 ; turn off fan

---

If you do use this, please note that the .gcode file has been hand coded--if you regenerate from the .STL file you'll lose this diagnostic section.

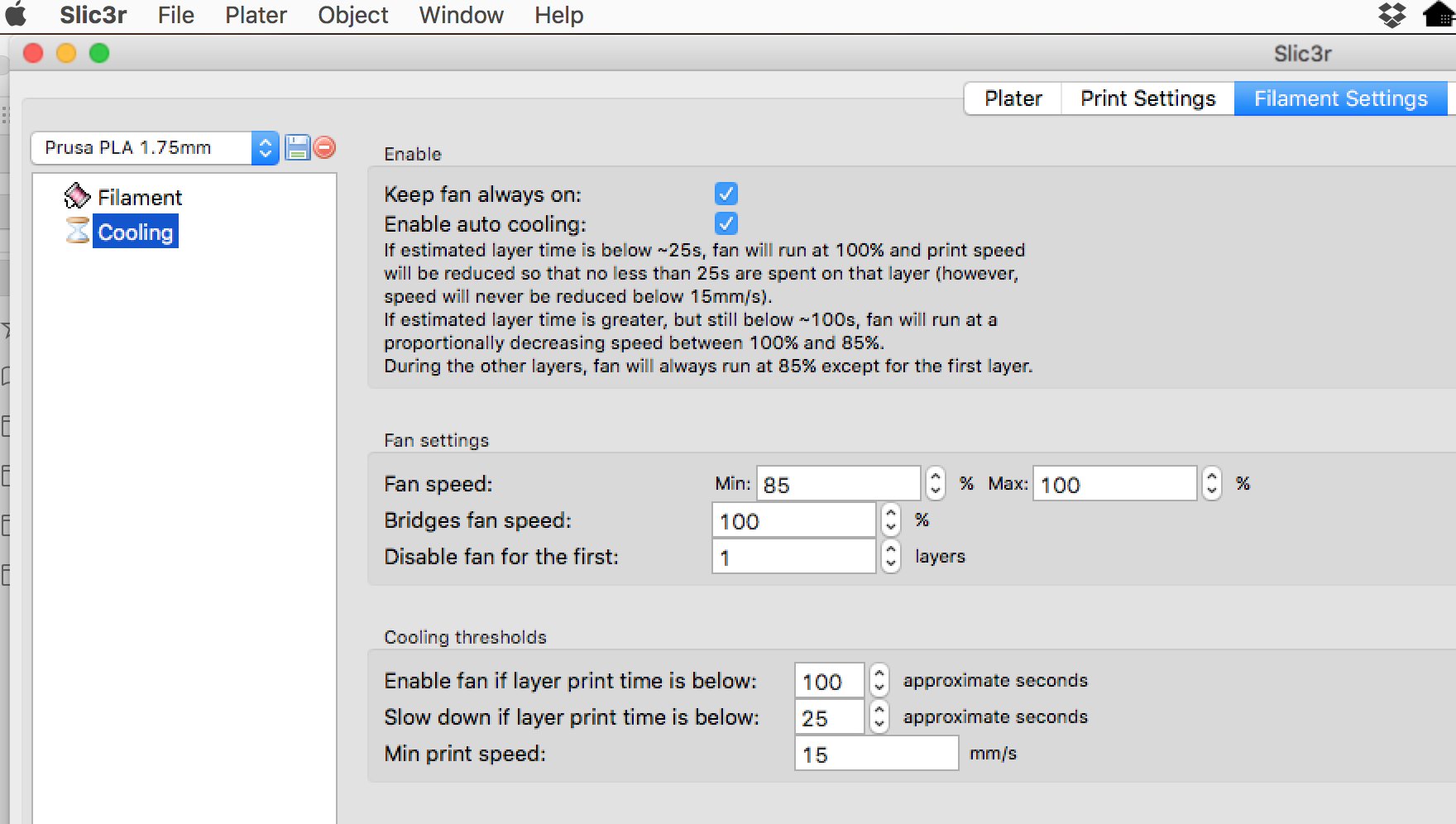

The default Slic3r configuration sets the auto cooling for PLA to vary between 85-100%. This setting is found in Filament Settings, select Prusa PLA 1.75mm preset, then click cooling. Mine is set to auto cool between 85%-100% (216 to 255 fan speed). I'm wondering if this is set way too high by default?

I just reloaded the config bundle Slic3r_config_bundle.ini dated July 6 to ensure I had the latest config file. What are the default cooling settings on your version of Slic3r?

How about you? What are your auto cooling settings? And can your heater keep up with the 100% fan?

For me, this is the second heater, third thermistor. I've just reprinted the fan shroud (but there was no difference). Odds are high that these aren't the problem.

Can anyone else reproduce this? What is the next step in diagnosing?

Re: Thermal Runaway with 3.0.6?

Curtis

I do not use Slic3r, but when printing PLA my fan is set to 100%.

The test I did was using the OctoPrint controls only.

I really don't have a clue what your problem is but I wonder if you have a dry solder joint on the RAMBo causing the heater to be under-powered? That really is my last thought on the matter. Sorry.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Thermal Runaway with 3.0.6?

Curtis

I do not use Slic3r, but when printing PLA my fan is set to 100%.

The test I did was using the OctoPrint controls only.

I really don't have a clue what your problem is but I wonder if you have a dry solder joint on the RAMBo causing the heater to be under-powered? That really is my last thought on the matter. Sorry.

Peter

Peter, you've been incredibly helpful--on all of my posts. Thank you for all of your help. At your earlier recommendation I purchased a 40W heater that I've not yet installed and might do so now.

Re: Thermal Runaway with 3.0.6?

Curtis,

> How about you? What are your auto cooling settings? And can your heater keep up with the 100% fan?

The fan will always cool down the nozzle and the bed. Both heaters are regulated in a PID loop. How much the nozzle and the bed will be cooled down depends on the distance of the fan from the bed, on the configuration of the objects already printed on the bed, on the G-code (how does the print head move, where it spends most of the time), on the component tolerances (fan shroud shape, fan speed tolerances, heater tolerances, thermistor tolerances) and on the PID control loop settings.

At the first layer the cool air gets reflected from the print bed. If the print bed is cold, that exaggerates the cooling effect. It is true that we at PR should have tuned up the system (software / firmware / hardware) to the component tolerances, but it seems there are some corner cases, where we are not there yet.

Also I believe that the print head cooling stress G-code you created is not a valid use case, so it does not have much meaning in the real world. I think it would fail at most printers. Indeed, in our Slic3r settings the fan is never enabled, when the print head is at the first layer.

> For me, this is the second heater, third thermistor. I've just reprinted the fan shroud (but there was no difference). Odds are high that these aren't the problem.

If I were you, I would either decrease the maximum fan speed, or disable the fan for more than a first layer. I think disabling the fan for the first 3 layers will certainly not hurt the print and lowering the fan speed to 90 or 80% of maximum will not hurt the print either. See the picture for the Slic3r settings.

Vojtech

Re: Thermal Runaway with 3.0.6?

Cura controls the fan a bit differently. There is a way for Cura to increase the fan speed smootly between the 2nd and xth layer. Maybe we should implement such behavior into Slic3r to avoid the cooling of the print head by the fan air reflected by the bed.

Vojtech

Re: Thermal Runaway with 3.0.6?

Vojtech

I don't think implementing the Cura-type fan increase would help as some users have reported this problem when printing solid top layers, so you would also need to implement a "Reduce fan speed when printing solid layers" option.

Having just replaced my part fan (the old one was blocked with dust and pet hairs) and having just started a print, I took another capture of my part fan turning on at 0.6mm layer height (see below at about -2 minutes):

I now see a temperature drop at 205 degrees), but that only lasts for a few seconds and is not unexpected.

The users who do have this problem must have some issue with the air flow direction, the heater cartridge, the heater cable, heater connection or the 12 Volt rail. Unfortunately, I am not is a position to be able to diagnose the problem. Give me a printer with the problem and I will find out why it happens.

Just one more thought. A standard mini RAMBo 1.3a will work happily on up to 16 Volts (limit is the fuses which have this rating). It would not be difficult to increase the voltage from the PSU to 13.5V (it just requires a small potentiometer adjustment and a multimeter). That would significantly increase the heater cartridge power without damaging any other components (OK, the bed would also heat up quicker...).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Thermal Runaway with 3.0.6?

Strangely, the issues I was having seem to have gone away on their own.

Re: Thermal Runaway with 3.0.6?

I think the shape of the model can play a part in this. Some models can deflect the airflow so that the nozzle/hotend is being blasted with air from the print fan and cause it too cool much more rapidly than normal. I also thing the design of the print fans nozzle I think, it is so small and close to the nozzle it makes the airflow more intensive, couple that with the shape of the model and the poor old hotend must feel like it's in a wind tunnel.

Re: Thermal Runaway with 3.0.6?

Hi, I tried the follwing (have problems with thermal runaway too on my new build MK2):

Printed an easy cube, which I use often for calibration. Sliced with Slic3r with latest Prusa settings and without cooling.

The cube size is 20mm. I waited the first 10 mm without any issues.

Then I turned on the fan manually via Tune menu. Value 180.

The fan has started as expected and then the temperature is gradually declined to a thermal runaway.

I checked the gcode file, it contains a M109 and not only a M104 what I had suspected.

So the controller is instructed to stabilize the temperature, but it doesn't (or can't)

Cheers Jens

Re: Thermal Runaway with 3.0.6?

At the first layer the cool air gets reflected from the print bed. If the print bed is cold, that exaggerates the cooling effect.

Also I believe that the print head cooling stress G-code you created is not a valid use case, so it does not have much meaning in the real world. I think it would fail at most printers. Indeed, in our Slic3r settings the fan is never enabled, when the print head is at the first layer.

> For me, this is the second heater, third thermistor. I've just reprinted the fan shroud (but there was no difference). Odds are high that these aren't the problem.

If I were you, I would either decrease the maximum fan speed, or disable the fan for more than a first layer. I think disabling the fan for the first 3 layers will certainly not hurt the print and lowering the fan speed to 90 or 80% of maximum will not hurt the print either. See the picture for the Slic3r settings.

I'm getting the thermal runaway when I'm on layer 2 (or 3?) and above. In the gcode I forced the fan on for the first layer so as to accelerate the test. By default it was set off on the first 3 layers (if I remember correctly).

If I might push back a little, this stress test might actually be a good one as it is the hardest test to fail. Every other test would be easier to fail. The bed is heated. If air is bouncing off the heated bed it should be even easier for the heater to recover from the fan blowing on it. Any other harder tests will also fail. Someone else mentioned that perhaps air is directed back at the nozzle by the shape of the model. Even if this were the case, it would be cooler air than that reflected from the bed, and therefore even harder for the heater to recover. Regardless, all of my thermal runaways were on roughly flat surfaces (i.e. level 3, just starting the infill).

Regarding the fan speed; are you saying the speed defaults should be lower than 85% and 100% for all machines? If so, I'm certainly willing to do so.

If my device is abnormal after the 2nd heater and thermistor, it seems that the next potential culprit is the 12V rail. I've tested it at rest. Is it possible that the voltage is fluctuating during print?

Re: Thermal Runaway with 3.0.6?

Curtis

It is unlikely that the 12V rail will fluctuate in use, but it is possible that there is a high resistance joint on the RAMBo which is causing the problem.

This can be tested by measuring the heater voltage across the screws of the plug connector on the RAMBo with the heater turned on.

As mentioned in my previous post, it is also possible to increase the voltage from the PSU; there is a small pot under the cover next to the output terminals.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Thermal Runaway with 3.0.6?

For the record I'm experiencing the same problem using some models I have created. It seems to be failing around layer 37. I'm printing ABS with default temps sliced by Simplify3D. I attached the g-code below in a zip file (wouldn't allow it unzipped).

This isn't an example that I cooked up, these are actually functional parts for my old 3D printer that I really would like printed.

Re: Thermal Runaway with 3.0.6?

It is unlikely that the 12V rail will fluctuate in use, but it is possible that there is a high resistance joint on the RAMBo which is causing the problem.

This can be tested by measuring the heater voltage across the screws of the plug connector on the RAMBo with the heater turned on.

As mentioned in my previous post, it is also possible to increase the voltage from the PSU; there is a small pot under the cover next to the output terminals.

I'm now getting a thermal runaway with nearly every print, including the Prusa logo model that I resliced.

I deleted all of the easy presets in Slic3r and then reimported the slic3r config bundles from the file MK2_Slic3r_prusa3d_1_7_3.ini, dated June 21, 2016. When I look at the Slic3r filament Cooling settings, I see the following boxes checked: Keep fan always on, enable auto cooling; fan speed runs 85% to 100% (which equates to 216 and 255 in Tune menu).

While it was headed for a thermal runaway (i.e the nozzle temp dropping) I measured the voltage at the top screws of the heater connector at the RAMBo board and found that it measured 11.89V. It dropped from at least 11.91 when I started measuring to 11.84 and then fluctuated some. Resistance across the heater is ~5.8 Ohms. Thus, the V^2/R = 24.4 W. My understanding is that while this is a bit low, it isn't outside the realm of possibility for a 30W heater.

The standard Prusa logo model that comes with the printer ALMOST triggers a thermal failure on the infill layers. I've attached both versions of the gcode just in case someone can see something that I can't. It appears that the key difference is that the default temp in the rescliced version is 215, and there is a z-hop in the rescliced version but not in the Prusa provided version.

I'm stumped--what is causing this?

I can certainly increase the voltage from the PSU or install a 40w heater. But that seems to be simply masking the problem, no?

Re: Thermal Runaway with 3.0.6?

Curtis

A drop of 0.05 Volts at the connector is not a lot, but it really should not happen. However, that drop could be in the meter leads or in the meter itself and is probably insignificant.

When you measured the resistance of the heater cartridge, did you also check that the meter leads were not adding a resistance? Check the resistance of the leads by touching the probes together.

11.9V is about right; the rail is probably at about 12.1V. A 24 Watt heater cartridge is a bit on the low side - I think mine is running at about 27W. If you increase the PSU output by about 0.5V, that should be enough to compensate for the lower output of the heater.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…