Size issues printing

Hello,

I've some issues printing gift boxes. In fact here the two items:

Christmas Gift Box

http://www.thingiverse.com/thing:197159

Lockable Present Ornament

http://www.thingiverse.com/thing:191974

I'm printing using Simplify3d (settings suggested by Josef) at 0.2mm resolution on a MK2.

As material, PLA.

The problem is I cannot close the boxes. Seems like the borders or the top is a little (very little) to thick...

Is that a common problem printing in PLA material?

Seems strange in the comments there is not such a problem with other users and I'm having this issue for the second time with different projects.

Thanks a lot,

Simon

Re: Size issues printing

I'd try it with the lates Slic3r Prusa edition, and see if that makes a difference.

Re: Size issues printing

Simon

Many issues of this nature can be simply down to slicing parameters. Others can be due to the model.

If you have a model with no overhangs, then you may find that you get more dimensionally accurate prints if you set the slicer to print the outer perimeter before the inner loops and infill.

If it's a problem with the mogel, slightly change the size of one part, say 100.1% (or 99.9%).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Size issues printing

Hello!

The model (the simplier) is this one: http://www.thingiverse.com/thing:197159

Really simple and there are no needs for supports or overhangs.

I know I could increase/decrease the size scaling, but that is not something I would like to do, because it would mean that every model I try to print should be scaled. Looking on the comments, all are happy, expect me 😉

If that's a slicing software issue, due parameters settings, than at least that would be a cause I could do something.

Actually I'm using Simplify3d. I'll try Slic3r Prusa edition and let you know.

I would like to find the main causes .-)

Simon

Re: Size issues printing

Well, looking at that model, the top is an almost exact fit onto the bottom; there is simply insufficient tolerance there for printing errors (about 0.2mm).

To ensure that it fits, you will either have to modify the lip on the top part, or be very accurate with your printing (and even then it may not work out).

You will need to print with 0.4mm extrusion width and print the outer perimeter first. You will also need to print slowly and possibly use Z-Lift and ensure that your filament is measured and extruder calibrated.

In all honesty, I would be easier to amend the lip of the top and redute its size by 0.3mm all round (not forgetting the corners.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Size issues printing

Hi Peter,

You will need to print with 0.4mm extrusion width and print the outer perimeter first. You will also need to print slowly and possibly use Z-Lift and ensure that your filament is measured and extruder calibrated.

What does this exactoly mean?

I'm using 0.2mm resolution. Does it means something other?

And what is Z-lift?

Sorry, I'm new on this world 😉

BTW I was thinking make a try with Slic3r Prusa version at 0.2 Normal or 0.15 OPTIMAL to look if something goes better.

Well, but if you think that the model starts already with a top that it's almost too perfect it's possible I'll not get any differences using this software 🙁

Simon

Re: Size issues printing

What does this exactoly mean?

I'm using 0.2mm resolution. Does it means something other?

And what is Z-lift?

Sorry, I'm new on this world 😉

Simone

Apologies the answers you are looking for are really not quick answers and many solutions come with experience.

I mentioned extrusion width, and you then took that to mean layer height. Width and height of the extrusion are quite different, but both are controlled by the slicer. As is Z-Lift, which is where the nozzle is raised higher than the printed part when performing non-printing moves.

Personally, I am not familiar with any of the slicers you mention, so I can't really advise on where to find the settings.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Size issues printing

Hello Peter,

About extrusion width, I've mentioned the Layer because I was thinking the layer (if heigth=0.2mm) is exactly the extrusion width. I'll try to understand this better. I've understoot the Z-lift, thanks!!

Well, I've tested Slic3r and the result is better compared to Simplify3D. I cannot tell you why, I mean, surely it's a matter of settings.

The result is that the box was easier to close. I've needed to sand it only a little bit. I'll use Slic3r Prusa Edition a little bit for next projects, using the settings saved/included. (I've seen there is a 0.15mm version which could be a good compromise between 0.2 and the high resolution of 0.1. I've a nozzle for 0.05 resolution as well, but let me learn with the default ones first 😉 ).

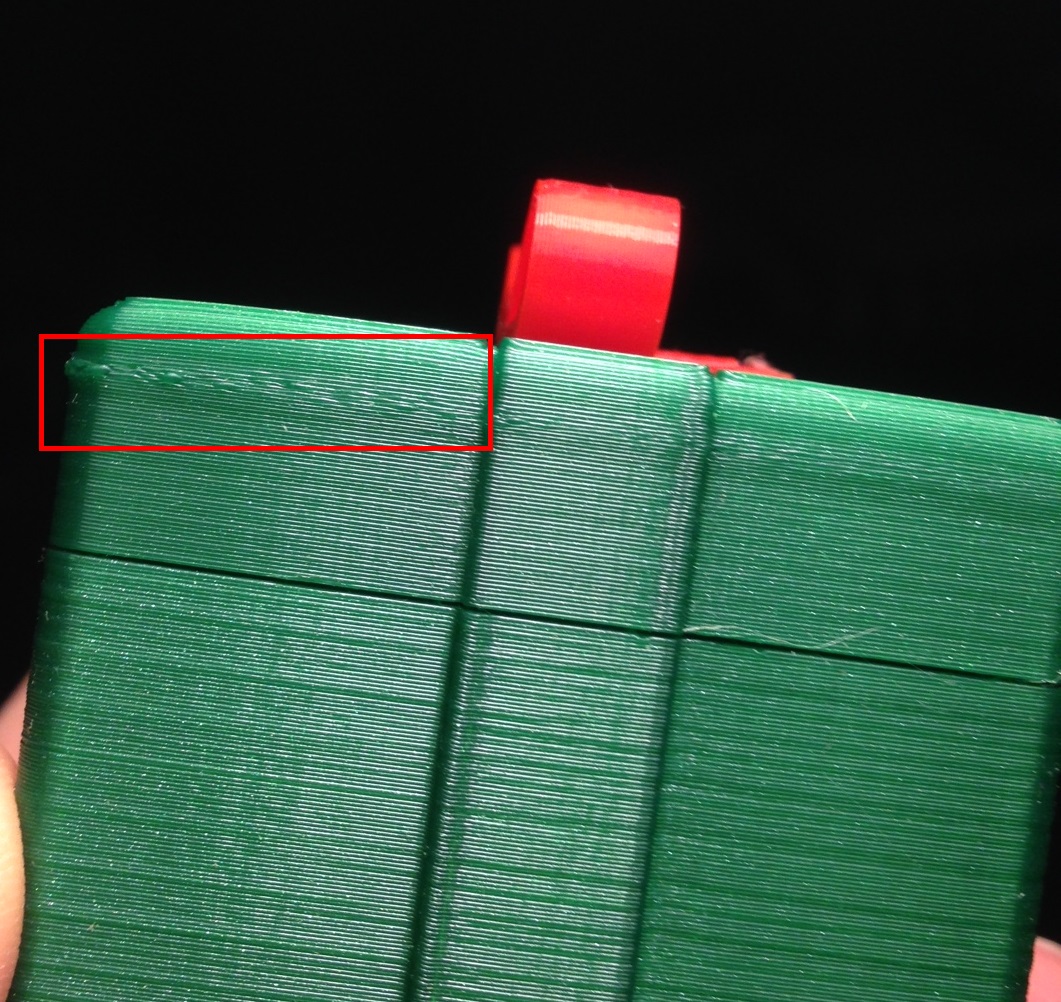

I've got an issue on a layer, here the image. Hope it's not depending on th gcode. For the rest it's better as mentioned above.

If you would like to compare the gcode generated, here:

There are many differences on the gcode.

Thank you!

Simon

Re: Size issues printing

Simon

For clarification, the nozzle as supplied with the Mk2 is 0.4mm diameter. This is capable of printing layer heights of 50 microns up to about 320 microns and a layer width of 400 microns to 500 microns (although wider and taller are possible, temps would need increasing and the finish can be very poor).

For your model, I would print 0.2mm layer height and 0.4mm extrusion width.

With regard to the area you highlighted in your printed model, do those layers correspond to the final full layers of the inside of the top?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Size issues printing

Good morning Peter,

Simon

For clarification, the nozzle as supplied with the Mk2 is 0.4mm diameter. This is capable of printing layer heights of 50 microns up to about 320 microns and a layer width of 400 microns to 500 microns (although wider and taller are possible, temps would need increasing and the finish can be very poor).

For your model, I would print 0.2mm layer height and 0.4mm extrusion width.

Thanks! I've purchased a 0.25mm nozzle as well, but I'll test it when I'll learn better those printers. Same for a 'Hardened steel E3D V6 Nozzle' purchased as well.

I'm still having difficult to understand the difference between heights and width. I'm thinking the extrusion like a wire, which has a circular section with a diameter of 'x', where 'x' is the layer height and the same time the width. If I print only one line at 0.2mm I'll have an extruded "snake" of 0.2mm of height and width. Maybe it's more complicated as told, so, I'll search some documentation 🙂

With regard to the area you highlighted in your printed model, do those layers correspond to the final full layers of the inside of the top?

Peter

I really cannot remember, I don't have the model here. It's possible that it's the final part where the printer has started to print the full base. The gcode could show you that.

Thanks a lot!

Simon

Re: Size issues printing

Simon

What is extruded is not circular; it is rectangular, but with rounded edges on the left and right.

The width of the extruded line is dependant on the nozzle size. The nozzle on the Nk2 is 0.4mm diameter and therefore the minimum width of the extruded line is 0.4mm. The maximum this should be set to is about 25% more than the nozzle diameter.

The layer height is what you select in the slicer and it is that (along with print speed) which mainly determines the quality of the finished print. You can set the layer height to anything between the printer's minimum resolution up to about 80% of the nozzle diameter.

With regard to your suggestion:

The gcode could show you that.

Yes, it probably would if I had the time to look. I am just another user trying to assist and I have a full-time job and family to look after. You asked for help; you also need to provide some input here...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Size issues printing

Don't worry Peter,

Thanks a lot for all your support proveded!

You gived me a great description for width and height, I've understood it, now 🙂

For the example, I'll try other settings and made experiences by myself.

I wish you and your family merry christmas and happy holidays.

Simon

Re: Size issues printing

Simon

Thanks for your understanding.

Have a great Christmas yourself!

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…