ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

Okay, I printed a benchy with support material and I notice that the layers contacting the support material is very loose and stringy. I have noticed this same issue with PLA and ABS. I was wondering if there are some good support settings that give a smooth surface while allowing easy removal. Thanks in advance. Please see pics below.

Re: ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

The benchy should not need support.

You are seriously under extruding. I am guessing a partial blockage, or severely wrong temperature, or loose hob pulley on the extruder stepper of something.

Details of your settings would be helpful, but I would first look at what is causing the under extrusion.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

[attachment=0]20170822_154021[1].jpg[/attachment]

Re: ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

Sorry, my internet has been horrible lately. Anyway, I have checked the pulleys and they are fine, my temps are 255 nozzle and 110 bed. My extrusion multiplier is 1. Also, I printed a test cube and every layer has normal extrusion, but it has the same characteristic as the benchy with the layer contacting the support material being loose and stringy. I will try to post some pics tomorrow as my internet just wont handle it at the moment.

Re: ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

Here are the pics of the test block I promised. The "test" side was printed on the bed with support material all around the text and inside the block:

Re: ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

For us to help you, please tell us what slicer you are using, and what settings you have tried. We can help from there.

But supports very a lot from slicer to slicer, and you have given no indications of what settings you are using,

That said, the hull of the Benchy makes me think something is really wrong.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

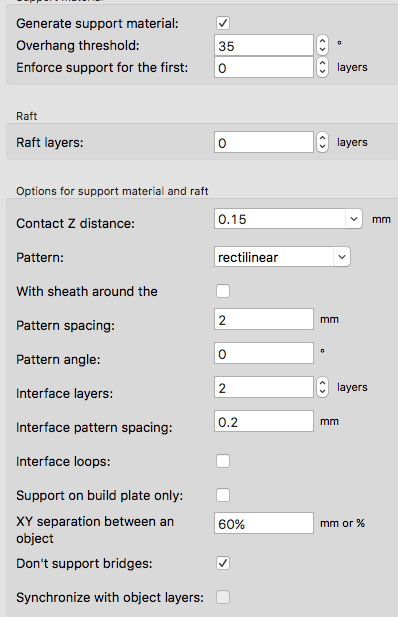

I have attached the support material settings for "SLIC3R Prusa Edition". This is the most recent try (what you see in the last pics). I started with the pattern spacing at 3mm and went down to 1mm and still had issues. Wanted to get some insight here before I wasted time and material. I have other settings if needed (tried to attach a word.doc file with everything but this forum doesnt seem to support that). Please let me know as I do not want to flood the thread with unnecessary info. Also, my speed is 30mm/s first layer and 50mm/s others, and fans are off.

Re: ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

You need some interface layers. I would add two.

Also your contact distance should be 0.2 at 0.3 there is too much play between the support and the surface which will make it rough.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: ROUGH PRINTS BETWEEN SURFACE AND SUPPORT

Okay, Ill try this on the test block and post the results. Thanks!