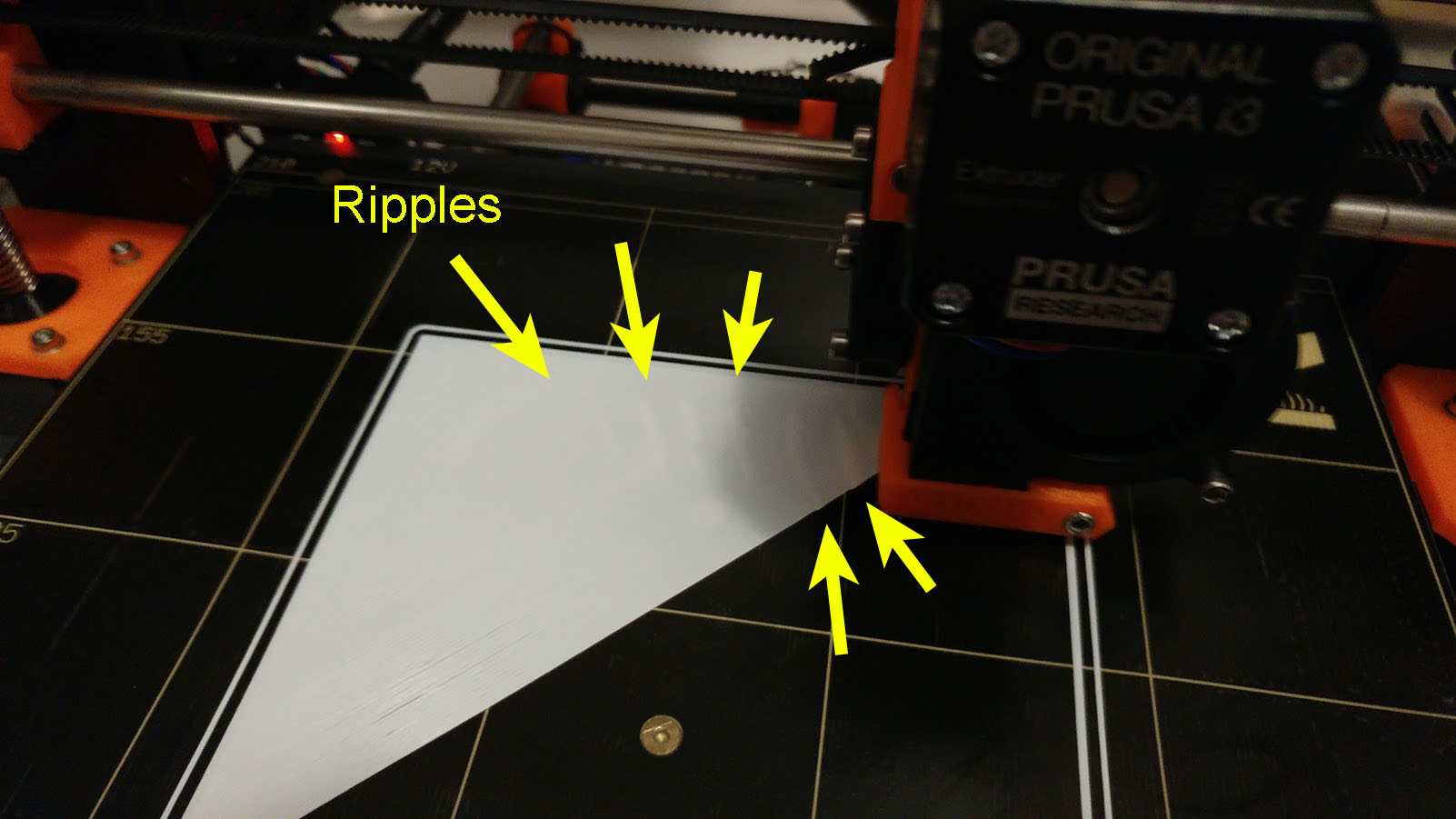

Rippling on layers

Why does this keep happening? The first layer prints fine, then the next few layers ripple like this. After about 5-6 layers when the infill starts things tend to even back out, but I don't know why this is happening. I tried adjusting the nozzle temp and heatbed temp up and down, but it didn't seem to have a huge change.

Re: Rippling on layers

Assuming that you have good layers then bad layers, I have seen this before, filament changes sizes or maybe not mixed correctly from the manufacture. I have seen this from filament manufacturers that do not have the correct feed back systems to control the diameter of the filament. An other possibility related to the filament is during the compounding of the filament, could be controls that meter the fillers and modifiers to the resin are not staying consistent. This would cause the viscosity to vary when at temp. Common on filaments from under capitalized companies.

There may also be some slicer setting that could correct this.

1. Filament diameter is almost never 1.75mm. We measure about 10 places spaced about 2 ft apart on the beginning of the roll and put in the value that we see most often. I guess you could average it.

2. Extrusion multiplier

3. Extrusion Width

Maybe some one else has some other factors.

Re: Rippling on layers

I know this is an old post, but I ran into the same issue yesterday, and there is still no conclusion to this issue.

It is also PLA, printing in an enclosure, the rippling is visible on the first two layers, and the ripple is visible always in the same area even when using different filaments, so it definitely has nothing to do with a specific spool or filament. Tried also speed variations 100-125%, but with no effect.

What I've noticed is that while the head is in that specific X-Y area, a rattling sound/resonance can be heard, even though all the screws and belts are tight.

https://www.dropbox.com/sh/g1681zusb430al8/AAC7gEYfFvE7CPZDaE8lJeYHa/Ripples/rattling.mp4?dl=0

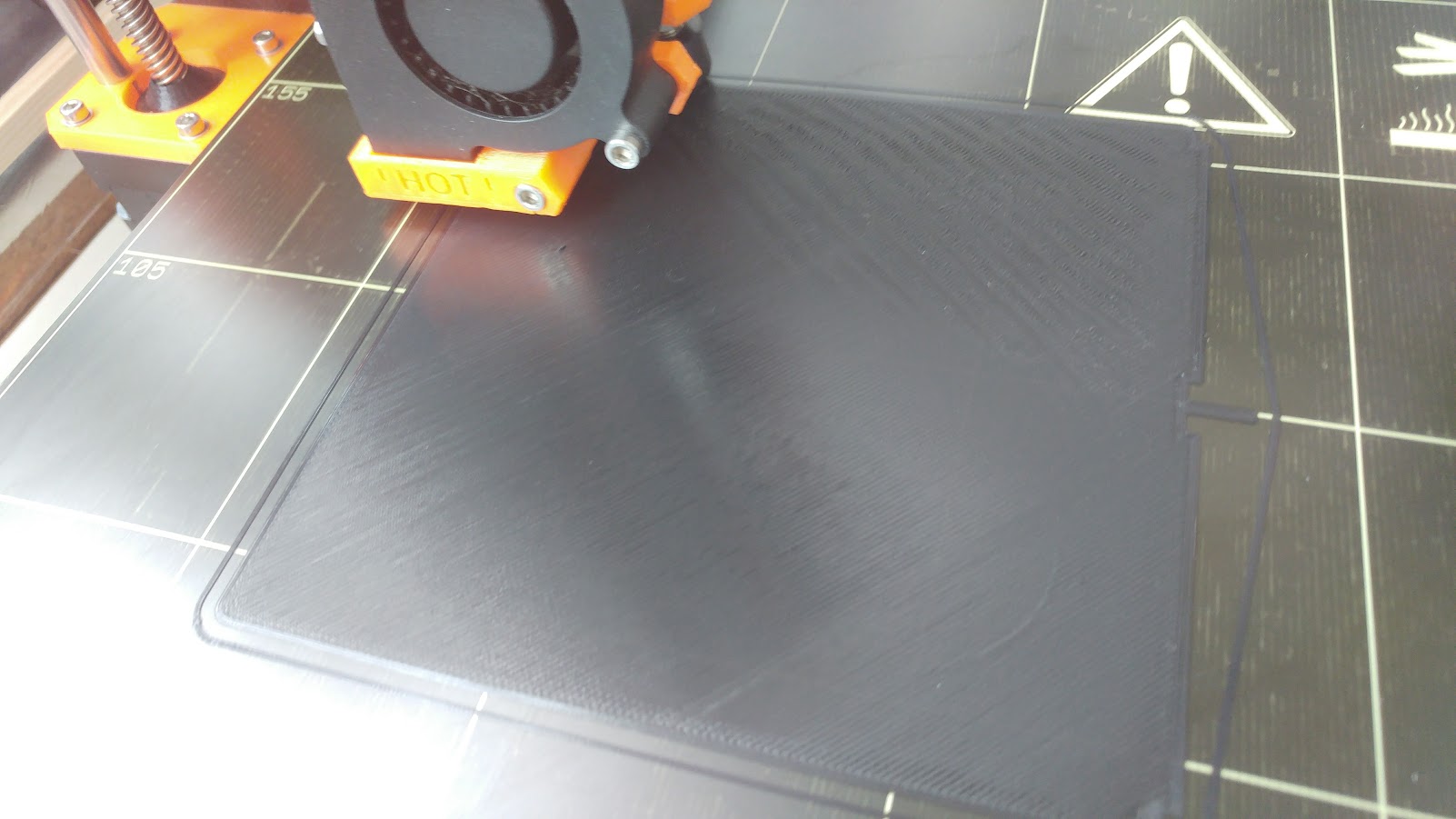

Here's the what it looks like with the black filament:

...and here's the white filament, practically the same problem at the same place, but with a slightly different ripple pattern:

Please, does anyone have any idea, since this is a recurring problem?

Thanks,

Jonnie

Re: Rippling on layers

Hey, I had exactly the same problem and was driving me crazy, fixed it before finding this thread doing exactly what was said above, measuring the diameter across the length, and adjusting the multiplier. Results came out great!

Re: Rippling on layers

Your first layer is too thin or you overextrude.

Thomas

Re: Rippling on layers

Generally that rippling or "baconing" effect is from the nozzle being a bit to close to the bed. Back off the Live z a little at a time and see how it goes.

Re: Rippling on layers

I just figured out what was causing the ripples in my case, since the rippling was always occurring in the same areas: I once used an old credit card to scrape the filament from the heatbed, and traces of the paint from that card remained on the bed. The paint was black, so it was hard to notice, and it was resilient to IPA. So I gave it a thorough rub with acetone until the paint was completely removed. It's all fine now! 🙂

Re: Rippling on layers

I just figured out what was causing the ripples in my case, since the rippling was always occurring in the same areas: I once used an old credit card to scrape the filament from the heatbed, and traces of the paint from that card remained on the bed. The paint was black, so it was hard to notice, and it was resilient to IPA. So I gave it a thorough rub with acetone until the paint was completely removed. It's all fine now! 🙂

Sounds like that made the distance from nozzle to bed just a bit less in that area which would make sense! Glad you got it going.

I have also found that if the ripple isn't to bad it will clear up in a layer or two and is fine unless you are like me and need a perfect looking layer no one sees!!

Re: Rippling on layers

Sounds like that made the distance from nozzle to bed just a bit less in that area which would make sense!

No, it was not the thickness of the paint. The paint was covering the PEI, so to filament would not stick to it.