problem of accuracy and flatness

Hello,

After several unsuccessfull trials, I have still two problems concerning the printing ( PLA) of a mechanical part ( see image) :

- one dimension is not respected ( -0,4 mm with respect to the drawing). I get most of the time, dimensions within 0,1 mm

- the underneath surface aspect is quite rough

I am using the basic adjustments proposed by Prusa slic3r ( 205°/55°, 0,15mm layer height, 3 rafts, contact distance 0,1 mm rectilinear, pattern spacing 1,5 mm).

Is that due to the geometry of the part ( bridge ) and why ? Any possibility to have an horizontal( and flat ) shell for the underneath surface ?

Independantly, two other questions :

- Most of the time, I need to hit the part to take it off ( bed at ambiant temperature, cleaning with IPA 90%) is that a normal procedure ?

- Concerning the ball bearings it seems that there are different approaches : add some grease/ oil on the rods or leave them as they are. Until now I just verify that the rods are clean , without dust, is that sufficient ?

Re: problem of accuracy and flatness

Printing over supports or a raft will always leave a more or less rough surface. No help for it with these kind of printers. I try to avoid rafts like the plague. Waste of filament and makes for ugly bottoms. Some slicers allow to create denser support structures and less distance between support and the actual object, making it increasingly harder to remove the support and still not giving great surface quality.

Out of curiosity: can't you lay the thing flat and avoid the whole raft & support mess?

With respect to the dimensional inaccuracy.. since you also mention prints sticking a bit harder than seems necessary, i do wonder if you're not having the so called "Elephant foot" problem. An elephant foot happens if you squish your first layer too much onto the bed, so the lines get wider (first one or 2 layers usually - better the further up u get) plus too much squish increases adhesion making t hard to remove the printed object. Maybe try raising the nozzle a bit?

Also, corners often end up being way to uh, wide i guess, throwing dimensions off as well. Printing slower for the outlines might help if that's the case.

Concerning the ball bearings: I ripped them out and replaced them with Igus bushings & matching rods like 4 months ago. By far the best modification i did to this otherwise great printer. Usually I try to pack wads of grease into rough ball bearings (after washing them out) prior to installing them and keep rods very lightly greased with Lithium Grease after that.

Otherwise i do prefer very light sewing oil on smooth rods.

Re: problem of accuracy and flatness

Thanks a lot stephan, as a newbie I appreciate...

1/ Raft and surface quality : I came to the same conclusion, avoid the « 2 bridges » design. In my case there is a mechanical advantage to proceed that way ( several parts interfacing together ) but 3D printing is not at all convenient. My parts will be now designed such that they will all present at least a flat surface ( a bit like a table with feet upwards ).

2/elephant foot / too much adhesion : you may be right, and I will make tests to analyse that problem. I have only redo some calibration tests in relation with your suggestions.

- First the Prusa v2calibration test seems first order OK as far as the criteria is a regular line ( as shown on Prusa documentation). The width of the line is # 1 mm, it seems in conflict with your « first one or 2 layers usually » ( as far I understood well,) ?

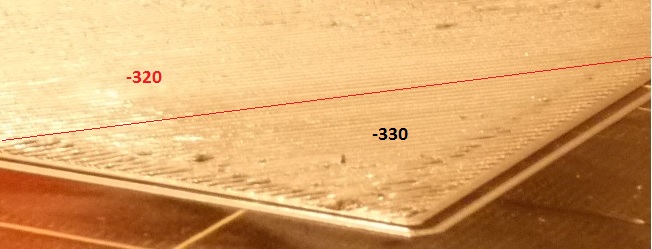

- I made a second test with Jeffjordan pattern ( see images) . My basic Z live is -330 microns / PLA / 205-215° / 55°c. The test shows that from -440 μ up to -420 μ there not a so big difference of terms of aspect. The start of the scanning at - 330 μ shows some scratches but the last sector is cleaner.(at the same Z = -330 μ )

When you say « raising a bit the nozzle », you mean for instance to use -320μ instead of -330 μ as far as the aspect sems good ( it is the case ) ?

In some way, what worries me too, is that dimensional inaccuracies do not apply to all dimensions but on a few. (Off course it is the one which as some importance !) . Don't you think that an « elephant foot » should affect all dimensions ? However I shall make tests with a slower printing as you suggest.

3 / Thanks for bearings info. I suppose that your machine is a clean environment, the dust is the ennemy too ! By the way how do you detect that it's time to change them ( noise, inaccuracies...) ?

Re: problem of accuracy and flatness

Here's some more info on "elephant foot":

https://all3dp.com/common-3d-printing-problems-3d-printer-troubleshooting-guide/#Elephant-Foot

http://support.3dverkstan.se/article/23-a-visual-ultimaker-troubleshooting-guide#elephant

When you say « raising a bit the nozzle », you mean for instance to use -320μ instead of -330 μ

Correct. at -320μ the nozzle is higher up than at -330μ

Going with JeffJordans calibration routine should get you properly sorted. I think -330μ still looks a bit rough, i'd try 320μ and maybe even 310μ, but to be honest, I am horrible at this. Takes me hours to get this right and i usually give up at a "eh, close enough for my needs" stage 😉

With respect the bearings it was very easy on my printer: despite having the printer in my basement, my wife complained bitterly about the noise of the printer running over night and demanded I do something about it. Also, my basement is horribly dusty, that was another reason why i wanted to go to Igus drylin bushings instead of ball bearings. Plus building an enclosure for it.

Re: problem of accuracy and flatness

Hi Stephan,

- Thanks for info, very helpfull to get a better idea of the origin of my inaccuracies. Moreover it seems, after a few more tests, that it is depending too on the orientation (axis choosen). I have to define some kind of jig and cumulate/ compare dimensions measurments after each parameter modification you mentionned. I hope that it is not a problem of repeatability. It's a long way …

note : I already knew that in Z direction, the bed is not so flat and still expect better performances in the XY plane !

-If you have some references related to the induction sensor ( Pinda) that would be nice. With respect to the nozzle, the difference altitude is 1 mm. I don't know if it is correct, Prusa doc doesn't say much about it : it is a non-linear sensor with a « noisy response » if too high . In fact I don't understand how it works and contributes to the calibration and possibly dimensions accuracy ( ?)

- Concerning the bearings and based on your experience, I will ask my wife to tell me when they should be changed...

Re: problem of accuracy and flatness

See http://www.thingiverse.com/thing:2050876

Note that the M501 command does not print any output for me (looking at the code, it prints only if a flag is set at compile time, which I assume isn't for 3.0.10). You can use M503 instead. (M501 reads settings from EEPROM to memory, M503 prints the settings from memory. If you have just powered up your printer you can just use M503, if you have already messed with the settings and want to check what's in the EEPROM you'll need M501 followed by M503 - but be aware that it will overwrite your settings in memory.)

I find that object to be too slow to print, which makes the process tedious given that usually the error is not too high to begin with. I've been thinking of putting together some Gcode that will print in minutes even at normal speeds (otherwise it defeats the purpose of the calibration) and still be reasonably easy to measure with a caliper. Last print I made came out with an error of less than 0.05mm though so I don't have much use of it at this point. 🙂

- Gab

Re: problem of accuracy and flatness

- Thingiverse reference : In the case of dimension inaccuracies due to over or undersized printing pieces, that procedure looks very attractive. Anyway I intend first to verify the source of the problem ( as far as possible ) with a calibration pattern close to the one proposed by Thingiverse.

Assuming that a gain modification is necessary, my problem is that I am not at all familiar with Gcode and don't quite understand if it as simple as presented « place in slic3r / Startup / Custom G-CODE a line , as an example of gain correction, such : M92 X100.21 Y100.37 Z400.00 E161.30 » ?

- I don' understand when you refer to M501/M503 commands, exept if your intent is to save the new parameters ?

Re: problem of accuracy and flatness

It is explained in the link I posted -

- You would use a USB connection to the printer to get a command console (Pronterface, Octoprint, etc.)

- You type the commands at the console and record the output for the current M92 values

- You determine the new M92 values with the provided formulas

- You enter the M92 code in the console, then enter M500 to save to EEPROM

This way you don't have to change your start Gcode.

- Gab

Re: problem of accuracy and flatness

Thanks but the topic does not exist anymore !