Print temp falling

Just recently my hotend has been unable to hold temperature once the print cooling fan is turned on. What could cause this to start happening out of nowhere? It only happens when the print cooling fan is turned on and never used to happen.

Re: Print temp falling

Craig

Check the heater plug on the RAMBo. Unplug and replug a couple of times and make sure it is seated properly.

What material and temps are you using?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Print temp falling

You might have to limit the fan speed on the software you are using.

Re: Print temp falling

Thanks for the responses. One of the first things I checked were the connections and nothing was loose. The temp has magically started staying consistent again though, so I shall not complain. Hopefully I don't run into the issue again. I was worried something on the board may have been failing. Also, I was using PLA and printing with an extruder temp of 210C and bed at 55C. I had also considered going the route of lowering the print fan speed during prints.

Re: Print temp falling

Was the printer near a window or door or some sort of draft? It sounds daft but thats all it can take sometimes to knock the temp down dramatically. If it goes too far it will throw a Thermal Overrun protection. In general it does drop and rise a few C though.

Re: Print temp falling

Hi

In addition to heater plug, there are two things I could see that could see that may explain the variation of cooling on the extruder:

the first one is the physical shape of the object being printed, that can reflect the air flow upward, the second one is that the result of the small fan duct, the one labelled with "HOT" sign, may not be that consistant from one printer to another.

I'm like Jon Snow, I know nothing.

Re: Print temp falling

Hi

I'm having the same issue 🙁

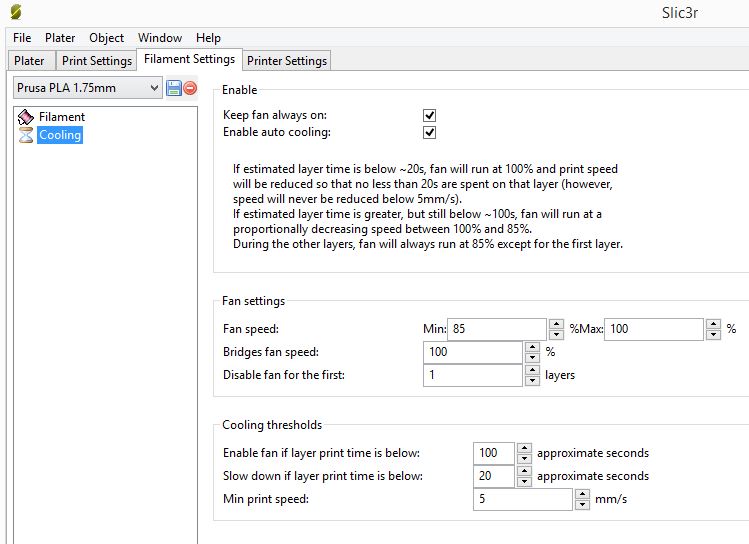

Where do i play with the HOTEND Fan settings ins slicer, is that even possible ? As this is a stafty feat....

Why does the temp. fluctuate in the first place ? Its always 237 degree to 241 and then down angain. I have a case so air flow is not an issue. Also this is happening on every print. So its not part depened....

Any advice ????

Thanks

PS: I know there is a thead somewhere who suggest playing with some firmware values but i can not find it anymore. Also this seems quite dangerous to ruin the printer.... But it would still be nice to find it again....

Re: Print temp falling

Manuel

The extruder fan must be running 100% all the time otherwise there is a possibility of filament blockage.

The printer is designed for the temp to hold at 210 to 215 degrees with the part fan at 100%. If you run higher temps then using the part fan will cool the extruder.

Peter

EDIT: I think you are looking for PID tuning: M303 S240 C8

Set the result using M301 Pxxx Iyyy Dzzz according to the results of the M303. I have this set in start GCode, so a printer reset will restore the original values.

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Print temp falling

Manuel

The extruder fan must be running 100% all the time otherwise there is a possibility of filament blockage.

The printer is designed for the temp to hold at 210 to 215 degrees with the part fan at 100%. If you run higher temps then using the part fan will cool the extruder.

Peter

EDIT: I think you are looking for PID tuning: M303 S240 C8

Set the result using M301 Pxxx Iyyy Dzzz according to the results of the M303. I have this set in start GCode, so a printer reset will restore the original values.

Hello Peter,

Hmm i see but as far as i remember even at 210 degrees the temp did fluctuate....

Thanks for the PID Tuning info. Would you care to elaborate a bit on that ?

What does the M303 S240 C8 code sequence do ?

What is the M303 Command, and what are the values for Pxxx Lyyyy and Dzzz ???

Is there a "PID codes manual" or a manpage somewhere ?

How does the storing of the old values work ?

You see i don't have any clue about those machine code stufff...,.

Thanks a LOT!

Manuel

Re: Print temp falling

Manuel

The GCode Wiki is here: http://reprap.org/wiki/G-code where everything is explained.

You only need to concern yourself with the Marlin variant.

The RAMBo firmware has the values hard-coded into it; these values can be overwritten using the M301 (extruder heater) and M304 (bed heater) and then they can be written into EEPROM (memory) for use after the printer has been restarted. Personally I prefer a restart to use factory defaults (just in case I make a mistake) so I do not write the values to memory and prefer to load them in start GCode.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Print temp falling

Manuel

The GCode Wiki is here: http://reprap.org/wiki/G-code where everything is explained.

You only need to concern yourself with the Marlin variant.

The RAMBo firmware has the values hard-coded into it; these values can be overwritten using the M301 (extruder heater) and M304 (bed heater) and then they can be written into EEPROM (memory) for use after the printer has been restarted. Personally I prefer a restart to use factory defaults (just in case I make a mistake) so I do not write the values to memory and prefer to load them in start GCode.

Peter

Hello Peter!

Thank you so much!

But i have one question:

In the Wiki it says to use this command: M301 H1 P1 I2 D3 ; Marlin so there is the H1 present. You don't seem to use it. So is it not needed ?

Also i would like to clear the process in my head:

1. I send the M303 S175 C8 command with ponterface to the printer

2. Ponterface (i never used it before) will report back some Pxxx,Ixxx and Dxxx numbers calculated out of the command above

3. I would use the M301 H1 P1 I2 D3 ; command (with the right values) and put in in Scli3r "Start Gcodes" (WHERE would i put it there? At the very beginning ?)

4. This will allow me to keep the prusa values in the EEProm and the gcode will sabalice the temp while printing.

Does this seem correct ?

It just occurred to me, as octoprint also has a command line feature, could i use octoprint instead of ponterface ?

Thanks a LOT

Re: Print temp falling

Manuel

There is only a single extruder heater, so the H1 is not required.

When running the M303 command, use the temperature that you normally print at. Run at least 8 Cycles (C8)

Yes, sent the M303 command via Pronterface (or OctoPrint etc). It will take a few minutes to run and you will see various outputs from the printer. It is the final output (it will tell you) that you use in the M301 command.

I use KISSlicer. Here is my current Start GCode section:

G21 ; [mm] mode

G90 ; absolute mode

M201 X1000 Y1000 E600 ; set default acceleration

M301 P24.24 I1.93 D75.95 ; set PID for extruder heater with sock

M304 P81.33 I3.91 D423.05 ; set PID for bed heater

M92 E175.5 ; Set Extruder Steps

M140 S<BED+5> ; Heat the bed + 5 degrees for Mk2

M109 S170 ; Warm it up to calib temp, and wait till it's warm

G87 ; Enable Babystep

G28 W ; Home all (no calbration)

G80 ; mesh bed levelling

M109 S<TEMP> ; Warm it up to print temp, and wait till it's warm

M83 ; Relative extruder

G1 Y-3.0 X50.0 F1000.0 ; go outside print area

G1 X100.0 E5 F1000.0 ; intro line

G1 E-1.5 Z2 F1000 ; Retract a bit and lift nozzle

G92 E0.0 ; Zero extruder

You should be able to determine from this the place to insert the GCode within Slic3r.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Print temp falling

I use Simplify3d across my many 3D printers. No issues. Try it, it is the best slicer out there in my opinion. Tweak able and the best and Fastest slicer.

I have no connection with the company that produces Simplify3d, I just use the software across my many 3D printers with great success.

Nigel

Life is keeping interested and excited by knowledge and new things.