Re: PET filament and print bed film blistering

I've noticed that some other printer makers recommend printing using different materials at regular intervals can help keep the blisters down...

Re: PET filament and print bed film blistering

I have been printing with PETG with Nozzle temp of 240 Deg C and Bed temp of 80 Deg C with 0.2mm first and subsequent layer height. I have no trouble removing my prints.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: PET filament and print bed film blistering

More good news: the trick of reducing the extruder temperature for the first layer definitely works. I printed a PETG model of a building with the first layer at 220C, the rest at 250C. It printed well and was easy to remove from the bed. Too easy, actually: the corners warped a little. So now I need to raise the adhesion again and find a happy balance. Thanks for the tips, everyone, especially the knowledge that PEI transitions at 217C. That's an important number to know!

I also got a BuildTak spatula based on recommendations. It's a surprisingly strong yet thin tool. I highly recommend it.

https://www.amazon.com/gp/product/B017XGEDOM

(Sorry, I have no pictures of the building I printed because I've already given it away and my good camera is in the shop. Next time!)

Re: PET filament and print bed film blistering

I played with PETG a little tonight.

I wasn't happy with my layer adhesion until I hit about 247-250C.

For bed adhesion, at that temperature, 55C is enough to get a decent stick. I tried 60C but felt that was a bit excessive (and left a pattern on the bed). I also drop my first layer speed to about 70%.

Honestly, you guys are overdoing it and essentially trying to club everything into submission with big hammers.

I may try some more complicated shapes later, but if I have any weird difficult prints, I will most likely apply glue stick on the tiny trouble spots (sharp corners and 180 degree perimeter turns which I can map out beforehand by looking at slic3r's preview) than crank up the bed temp. If there's a choice between damaging my bed and using a glue stick, I'll go ahead and use a glue stick.

Re: PET filament and print bed film blistering

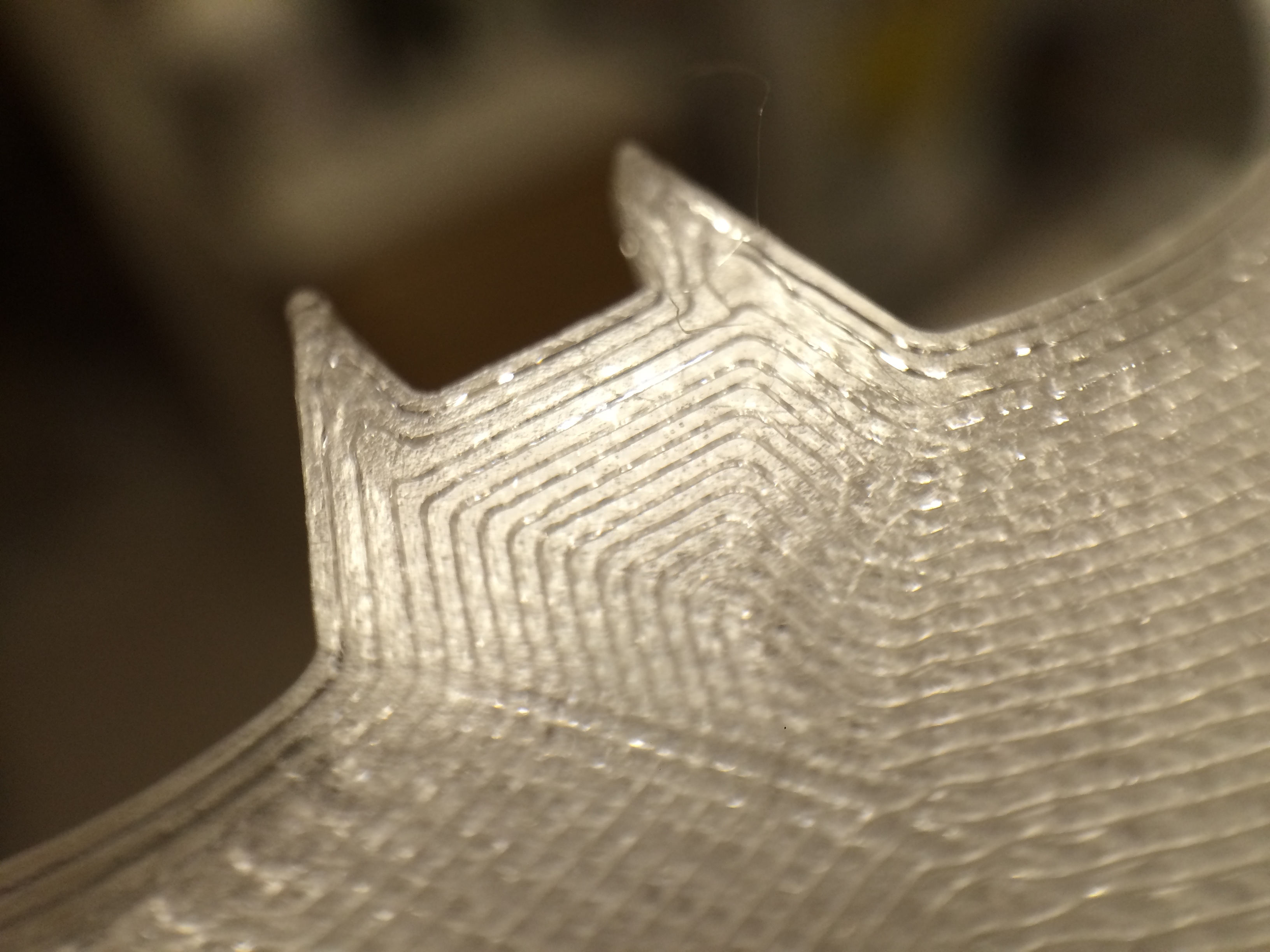

I sliced up a Batman to try out with PETG.

I went with 250C extruder, 55C bed temp. Looking at the model, I already know where the trouble spots will be -- the ears and the wing tips, and maybe the other little sharp corners. So I dropped a little glue stick at the ears, the tips, and at the very bottom.

This is what removing it looked like.

If you look closely at the layers, I don't even squash and deform the Hell out of my first layer or overextrude it.

Re: PET filament and print bed film blistering

So I have been doing quite a lot of printing lately in PETG from Esun recently and will say that I love it. The low shrinkage and High strength of parts make perfect for me. As I do Not have a MK2 i can only speak of my experiences of printing on Glass With some hairspray. For the first layer I have my bed level set so that there is hardly and friction between the nozzle and business card, then for my bed temp I'm back and forth between 60c and 70c, and initial layer speed of 12mms. If PEI adheres as good as everyone seems to say I would try lowering the bed down to 50c or so and going from there. Also is there any info on how thick the PEI on the new prusa bed is? Most people who seem to use PEi stuck to a glass bed seem to be going with a 1mm PEI sheet with high temp 3M transfer tape with no blistering problems as I'm reading here.

Re: PET filament and print bed film blistering

Constantine

PEI info is here: http://shop.prusa3d.com/en/3d-printer-parts/109-replacement-pei-sheet-ultem.html

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: PET filament and print bed film blistering

Hi,

just made a test based on what is discussed there, using PETG from RepRapper, with 225 °C / 50 °C for first layer and 240 °C / 60 °C for following layers.

Results are encouraging, everything stick well but is quite easy to remove. However I had a small warping on long thin parts (I printed this: http://www.thingiverse.com/thing:840290 ). So maybe a bit of glue could have helped, or a bit of brim. I'll try to increase the headbed temp a bit for the first layer.

I'm like Jon Snow, I know nothing.

Re: PET filament and print bed film blistering

I had a long thin print today which also lifted a little at the corners, so I bumped my bed temperature up a little. Its just something that you play with based on printer and material.

For objects that I control, sometimes I prefer to add adhesion discs to problem spots instead of other more drastic measures. Faster to print, less material used, more effective, and faster to snip off than an entire brim.

Would probably be a reasonable feature to add to the slicer.

Re: PET filament and print bed film blistering

Constantine

PEI info is here: http://shop.prusa3d.com/en/3d-printer-parts/109-replacement-pei-sheet-ultem.html

Peter

Thanks for the link! It is quite thin as suspected, but I still think lower bed temps should take care of most of the issues. I'd like to see someone try a thicker sheet though.

Re: PET filament and print bed film blistering

My 2 cents..

I tried tglase PET on a PEI board and had some luck after proper cleaning with Isopropyl Alcohol and then a layer of gluestick. However parts kept getting unstuck and I was trying to print 100 x tiny tall things with a 2 layer bed adhesion per part! Not easy on any printer except it does it fine with PLA. once one piece falls over and gets caught then rest follow and the print is gone. Client needs the parts ASAP! I was using 90 Degree bed temp as the default settings provided by Prusa Research in Slic3r. Needed an alternative quickly..

So I used some crappy old white (PVA) glue that was a glob of almost dry mess, watered it down heaps and mixed it up until it was like thick milk. may be 1:8 ratio-ish. Cleaned the bed again and layered it on thinly. The PET pieces stuck totally sweet with such a small footprint! I also added 1.5mm Z lift to the settings as I noticed there were tiny bits catching as the hotened moved over all the pieces as they were printing. Nothing dislodged and all is good in 3d printer land once again 🙂 The PVA washes off really easy once it's wet again and then some Isopropyl Alcohol can be used to make sure it's totally gone for a different material.

I would totally switch to a Glass bed though as in my other printers but the sensor needs to be so close to do it's auto calibration thing I don't think I'm gonna find a 1mm sheet of glass 🙁

Re: PET filament and print bed film blistering

if you want 1mm thick glass use a iPad tempered glass protector. I had great success with PetG on my MK1 using this. 90 degree bed temp. let it cool completely after print and the print just lifts off.

Having said that I have found PetG fine on the MK2 but using Print Stick as suggested in the manual.

Ken

Re: PET filament and print bed film blistering

My 2 cents..

I tried tglase PET on a PEI board and had some luck after proper cleaning with Isopropyl Alcohol and then a layer of gluestick. However parts kept getting unstuck and I was trying to print 100 x tiny tall things with a 2 layer bed adhesion per part! Not easy on any printer except it does it fine with PLA. once one piece falls over and gets caught then rest follow and the print is gone. Client needs the parts ASAP! I was using 90 Degree bed temp as the default settings provided by Prusa Research in Slic3r. Needed an alternative quickly..

So I used some crappy old white (PVA) glue that was a glob of almost dry mess, watered it down heaps and mixed it up until it was like thick milk. may be 1:8 ratio-ish. Cleaned the bed again and layered it on thinly. The PET pieces stuck totally sweet with such a small footprint! I also added 1.5mm Z lift to the settings as I noticed there were tiny bits catching as the hotened moved over all the pieces as they were printing. Nothing dislodged and all is good in 3d printer land once again 🙂 The PVA washes off really easy once it's wet again and then some Isopropyl Alcohol can be used to make sure it's totally gone for a different material.

I would totally switch to a Glass bed though as in my other printers but the sensor needs to be so close to do it's auto calibration thing I don't think I'm gonna find a 1mm sheet of glass 🙁

I use a glass bed on my Prusa with no issues.

http://www.prusamk2.com/printing-on-glass-with-youre-prusa-i3-mk2-ohhh-so-smooth/

Personally I edited the gcode scripts to increase the time between attaching the glass bed to allow the glass to warm to the right temperature.

I use this for printing ABS and PETG (kapton tape, ABS slurry). No issues at allow.

Re: PET filament and print bed film blistering

I just opened a new PETG spool and tried it.

This one seems to need higher temperature and to have higher viscosity but using 235 °C for extruder and 55°C for bed on first layer then 260 °C for extruder and 60°C for the others layer just allow me to print as intended.

Adhesion is just fine and object can be unstuck withour too much effort after the print, without any glass, glue layer or anything aprat the standard PEI bed.

I'm like Jon Snow, I know nothing.