Oozing / stringing

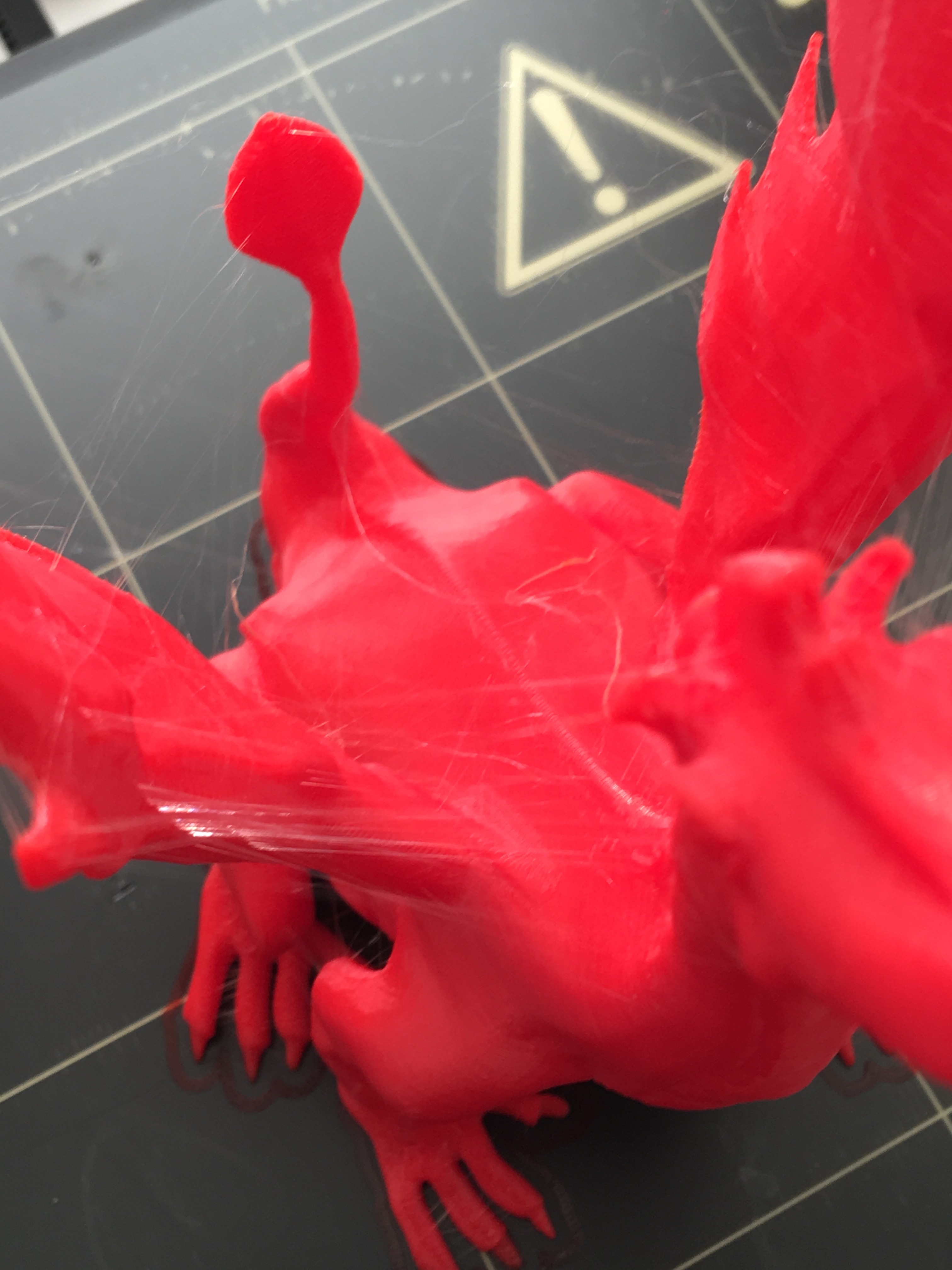

I printed this copy of Adalina in PLA which turned out ok except for the oozing and stringing. You can see it in the pictures below.

I used the August 30 Simplify3D profile .2mm layer height (215 degrees first layer, 200 degrees for all other layers), with the following modifications:

retraction distance: 1 mm

retraction vertical lift 0.15mm

retraction speed 2400 mm/s

Any tips for how I can reduce the oozing/stringing?

Thanks!

Re: Oozing / stringing

Try increase the retraction a bit?

Found alot of good info here: https://www.matterhackers.com/articles/retraction-just-say-no-to-oozing

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: Oozing / stringing

Is it Prusa PLA?

215C can be too much for some PLA filaments

Re: Oozing / stringing

Is it Prusa PLA?

215C can be too much for some PLA filaments

I think the PRUSA PLA is specified to print pretty hot, but it could be the first test to do... lower the temp to 190 or so.

Me on MyMiniFactory!

Me on Instagram

3D Printing Live Feeds

Prusa MK2 Usergroup Slack Live Chat

Unofficial live chat by users for users.

Re: Oozing / stringing

Joshua

I would reduce retraction to 0.6mm, and lower the retraction speed.

Extruder speed is limited in firmware to 25mm/sec and it has been noted previously that having the speed set above that value can actually cause slower retraction.

You could also try printing slower, fan at 100% and not using Z-Lift (which can also cause stringing).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing / stringing

Joshua

I would reduce retraction to 0.6mm, and lower the retraction speed.

Extruder speed is limited in firmware to 25mm/sec and it has been noted previously that having the speed set above that value can actually cause slower retraction.

You could also try printing slower, fan at 100% and not using Z-Lift (which can also cause stringing).

Peter

I remember reading in one of Prusa's how-to guides him saying not to use firmware retraction, as it is way too fast. These two statements seem to be mutually exclusive.

Re: Oozing / stringing

and not using Z-Lift (which can also cause stringing).

+1

While I'm still cutting my teeth on the MK2, I've used 5 types of PLA from 4 vendors. I found 3 wood PLA filaments (ColorFabb bamboo, ColorFabb cork and Robo3d wood) to be *very* stringy when using the default PLA settings. Lowering the extruder temperature and, more importantly, turning off Z-Lift eliminated most of the stringing in my prints.

Kevin

Re: Oozing / stringing

Joshua

I would reduce retraction to 0.6mm, and lower the retraction speed.

Extruder speed is limited in firmware to 25mm/sec and it has been noted previously that having the speed set above that value can actually cause slower retraction.

You could also try printing slower, fan at 100% and not using Z-Lift (which can also cause stringing).

Peter

I remember reading in one of Prusa's how-to guides him saying not to use firmware retraction, as it is way too fast. These two statements seem to be mutually exclusive.

Hmm....so which is which?

Re: Oozing / stringing

Joshua

I would reduce retraction to 0.6mm, and lower the retraction speed.

Extruder speed is limited in firmware to 25mm/sec and it has been noted previously that having the speed set above that value can actually cause slower retraction.

You could also try printing slower, fan at 100% and not using Z-Lift (which can also cause stringing).

Peter

I remember reading in one of Prusa's how-to guides him saying not to use firmware retraction, as it is way too fast. These two statements seem to be mutually exclusive.

Hmm....so which is which?

The Prusa default in slic3r is .35. If the hardware is limited to 25, even the default is too fast (or ignored). But that doesn't jive with Josef's article saying the hardware is too fast. So I'm confused.

Re: Oozing / stringing

I remember reading in one of Prusa's how-to guides him saying not to use firmware retraction, as it is way too fast. These two statements seem to be mutually exclusive.

Hmm....so which is which?

The Prusa default in slic3r is .35. If the hardware is limited to 25, even the default is too fast (or ignored). But that doesn't jive with Josef's article saying the hardware is too fast. So I'm confused.

I would like to know definitely what's going on here as well as if the hardware is limited to 25 in firmware and the software setting does nothing then I've been pissing away a lot of time testing retraction speeds with different materials.

Re: Oozing / stringing

I can't find the original article wherein I read that the internal retraction is too fast.

Here is an article where he describes gcode retraction with distance of 1mm and speed of 30mm/s

http://prusaprinters.org/slic3r-and-marlin-configuration-for-reprap-firmware-retraction/

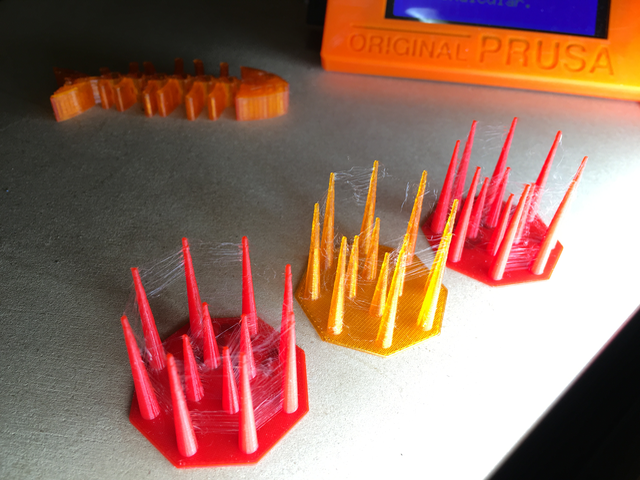

Without trying to thread jack, I've not found any combination of temp, distance, or speed fixes the stringing I'm experiencing with Hatchbox PLA, temp=185. Orange is speed 35, 0.7mm retraction, red to the right is 0.9mm, speed100, red to the left is 2mm, speed 100

Increasing temps causes ooze during the mesh bed leveling.

Re: Oozing / stringing

I have no idea why firmware retraction (G10/G11/M207) has been brought into the subject.

The maximum print and travel speeds are defined in the firmware:

// The axis order in all axis related arrays is X, Y, Z, E

#define DEFAULT_MAX_FEEDRATE {500, 500, 1000, 25} // (mm/sec)

There were versions of Marlin where exceeding the MAX_FEEDRATE caused problems; it has supposedly been fixed, but judging by the faults within Marlin that Vojtech has found, there could still be issues in that area.

Incidentally, firmware retraction can be used and the speed/distances are set using M207. I have not used a slicer which generates firmware retraction codes.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing / stringing

I have no idea why firmware retraction (G10/G11/M207) has been brought into the subject.

The maximum print and travel speeds are defined in the firmware:

// The axis order in all axis related arrays is X, Y, Z, E

#define DEFAULT_MAX_FEEDRATE {500, 500, 1000, 25} // (mm/sec)

There were versions of Marlin where exceeding the MAX_FEEDRATE caused problems; it has supposedly been fixed, but judging by the faults within Marlin that Vojtech has found, there could still be issues in that area.

Incidentally, firmware retraction can be used and the speed/distances are set using M207. I have not used a slicer which generates firmware retraction codes.

Peter

Thanks for the confirmation, Peter. It is helpful for me to know that setting a speed any higher than 1500 in S3D will not do anything, and would only potentially hurt.

Re: Oozing / stringing

I have no idea why firmware retraction (G10/G11/M207) has been brought into the subject.

The maximum print and travel speeds are defined in the firmware:

// The axis order in all axis related arrays is X, Y, Z, E

#define DEFAULT_MAX_FEEDRATE {500, 500, 1000, 25} // (mm/sec)

There were versions of Marlin where exceeding the MAX_FEEDRATE caused problems; it has supposedly been fixed, but judging by the faults within Marlin that Vojtech has found, there could still be issues in that area.

Incidentally, firmware retraction can be used and the speed/distances are set using M207. I have not used a slicer which generates firmware retraction codes.

Peter

In the MK2 branch, file 1_75mm_MK2-RAMBo13a-E3Dv6full.h, I see the following which indicates a much greater extruder feedrate is possible:

#define DEFAULT_MAX_FEEDRATE {500, 500, 12, 120} // (mm/sec)

Did I miss something? Does this mean that in an attempt to minimize stringing, we can go up to 120 from the default of 35?

Re: Oozing / stringing

Curtis

Apologies; you are indeed correct. For some reason, I have V3.0.5 loaded as current firmware, and 3.0.7 as previous version. Obviously a mistake on my part.

The only thing I will say is that the organisation of versions on Github is not great and is something I have mentioned before. I note that 3.0.8 was released on Sept 1st, yet there are amendments to that version on GitHub from only 6 days ago.

Yes, 3.0.8 will allow extruder speeds of 120mm/sec; I think this was introduced to allow fast retraction on filament changes. However, for move retractions, acceleration will significantly limit the maximum speed. According to Josef, the acceleration for the extruder is 600mm/s^2.

I am not a great mathematician, but my thoughts would be that if the speed was set to 120mm/sec, it would take 0.2 seconds to reach that speed and in that time, about 25mm of filament would have been retracted. As a maximum of 1mm retraction should be required, then retraction will occur at less than 25mm/sec.

Acceleration would be constant for any speed setting up to the required speed, so setting retraction greater than 20 to 25mm/sec would be pointless for the maximum retraction of the V6 extruder.

Peter

And I think I acquitted myself quite nicely 😉

EDIT: despite what Josef has previously stated, I see that default retraction acceleration is set at 1500mm/s^2... There's my theory up in smoke... 😥

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing / stringing

Yes, 3.0.8 will allow extruder speeds of 120mm/sec; I think this was introduced to allow fast retraction on filament changes. However, for move retractions, acceleration will significantly limit the maximum speed. According to Josef, the acceleration for the extruder is 600mm/s^2.

I am not a great mathematician, but my thoughts would be that if the speed was set to 120mm/sec, it would take 0.2 seconds to reach that speed and in that time, about 25mm of filament would have been retracted. As a maximum of 1mm retraction should be required, then retraction will occur at less than 25mm/sec.

Acceleration would be constant for any speed setting up to the required speed, so setting retraction greater than 20 to 25mm/sec would be pointless for the maximum retraction of the V6 extruder.

Your math is quite correct--and then I lose you at the last 25mm/sec.

120mm/sec / 600mm/s^2 = 0.2s to reach full speed.

Even assuming you were already at full speed (120mm/sec), the max extrudable filament is 120mm/sec * 0.2sec = 24mm. The reality is some bit less as the extruder may not be at full speed. I've forgotten too much calculus to figure the actual.

Where I lose you is the assumption of 1mm retraction required. This seems an arbitrary number. I think the Slic3r default is 0.7 (or 0.8)mm. I've seen some people with 2 or 3mm retraction.

And I think I acquitted myself quite nicely 😉

Yes, yes you did! As you always do.

EDIT: despite what Josef has previously stated, I see that default retraction acceleration is set at 1500mm/s^2... There's my theory up in smoke... 😥

And yeah, that's a monkey wrench. It means that the full speed is 120mm/sec/1500mm/sec^2 = 0.08s to reach full speed. The max extrudable filament doesn't necessarily change.

Re: Oozing / stringing

Where I lose you is the assumption of 1mm retraction required.

Curtis

I believe that is the maximum retraction value specified by E3D; any more and there is a danger of blockage (soft filament being drawn into heat break area and solidifying in the small gap at the end of the PTFE tube).

When the Mk2 was first released the default Slic3r profiles used retraction of 1.5mm and several users (including myself) had blocked filament paths very quickly. The retraction settings were then amended to 0.8mm.

However, I don't believe that the retraction was the cause of the blockage; I had a V6 extruder on my Mk1 for 6 months before the Mk2 was released and I was using 1.5mm retraction. When I had the blockage on the new Mk2, I rebuilt the extruder and carried on using 1.5mm retraction settings without issue. I concluded that it was the hot end assembly process that was faulty (PTFE tube not square or not inserted fully).

Peter

Just a bit more on acceleration... At 1500 mm/s^2, after 0.1 second, the speed reached would be 150mm/s and 7.5mm of filament would have been retracted. At 0.05 second, the speed would be 75mm/s and 1.87mm of filament extracted. At 0.025 second, speed 37.5mm/s and 0.46875 mm retraction. Therefore the terminal speed when retracting 1 mm of filament will be a maximum of ~50mm/s, assuming linear acceleration and ignoring the "Jerk" value which I believe will be included in the calculation of the starting speed.

In addition, I note that Slic3r which apparently "intelligently" handles acceleration has a default value of 1000mm/s^2 which, if it does do what is says, will override the firmware settings, reducing the 50mm/s

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…