MK2S print edges curl

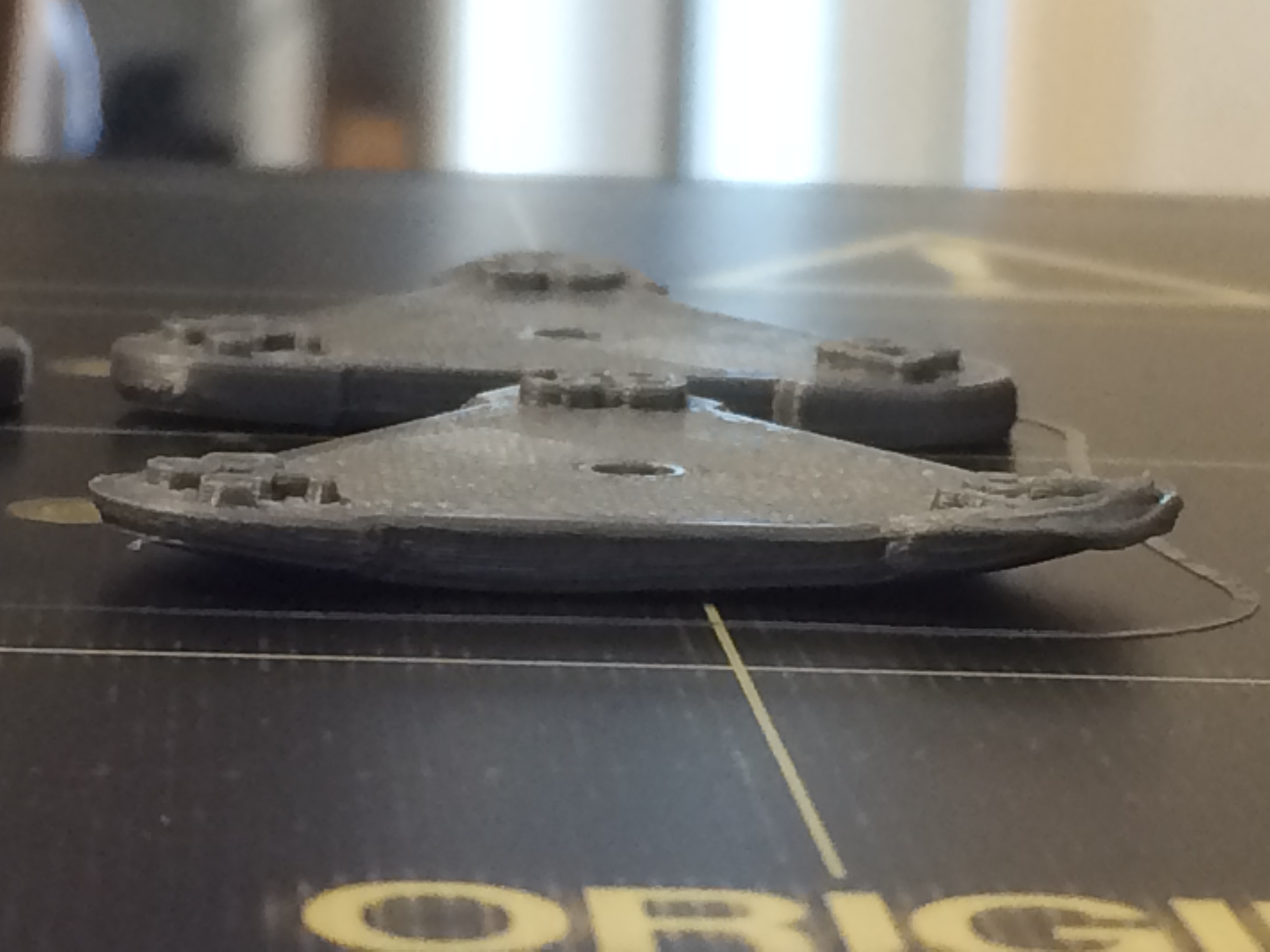

We are having trouble with our print, sometimes the print prints flat and fine but other times towards the end of the print it starts to curl up at the edges. We have tried printing a single object and we have tried printing multiple of the same object at the same time and it happens in both circumstances. We are printing with PLA, have tried 50 and 60 for extruder temp(seems to work better at 60) and bed temp at 200. We have tried cleaning the bed with alcohol and with acetone. When we turn the extruder temp up to 60 it will drop back down to 50 during the print. This is our first printer and this is causing some frustration. Any help would be appreciated. Picture shows a multiple print and you can see the object in the back printed properly but the object in front curled up.

Re: MK2S print edges curl

I think you have you temps reversed. Try extruder at 218 and bed at 60. The other possibility is that your Z adj is off, in other words the height of the nozzle to the bed is too great. If your P.I.N.D.A. probe is 1mm above the nozzle tip your Z adj should be 550 to 650. The larger the number, the closer to the bed. Make sure the calibrations are successful.

Original Prusa I3 MK2s with 2.5 upgrade; Original Prusa I3 MK3s; Slic3rPE; FreeCAD

Re: MK2S print edges curl

Do the things that andyldavis posted first! If that doesn't help:

Also make sure to clean your print bed: There is some special alcohol for cleaning (don't know the word for it in English!) which works best for me.

On some prints you may also need to add brim. You can find it under "Printing Settings" > "Skirt & Brim". 10mm should be a good value to start.

You may also use some glue (the one that was delivered with your printer). But be aware that it might be very hard to remove the print from the printbed!

Re: MK2S print edges curl

Gord,

As davis and chrostoph worte, the parts should be able to get to print well.

They are not too large, PA is easy to print, only the fact that the corners of the part have a rather smaller contact surface on the bed and there is a large triangle shape which will generate some warping force is making it a little more challenging.

First thing is to have the clean print bed -which you seem to have covered since you cleaned it with alcohol and even acetone.

Hint: lacohol concentration should be as high as possible, 96% isopropyl alcohol from the drug store is good. Also note that alcohol is extremely hygrophobic, i.e. it absorbs water from the air like crazy and that reduces it's effectiveness for cleaning. Keep in glass bottle and minimize the time the alcohol is exposed to air.

Next thing is the first layer thickness: in your photo it actually looks as if the first layer is too thin. Teh skirt around the print is very wide and very thin. Refer to the manual to adjust to the correct height. Watch the print during the first layer. It should be smooth (ripples --> nozzle too low) and there should be no gap between the individual extrusion lines (gaps--> nozzle too high)

If you still get curling of the edges try Brim (I think 5mm might also be enough) to increase the adhesion of the corners further.

Increasing heatbed temperature also helps as you noticed in your email.

Good luck!

Re: MK2S print edges curl

For setting Live Z to improve adheasion.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…