Is my PINDA broken because it deforms?

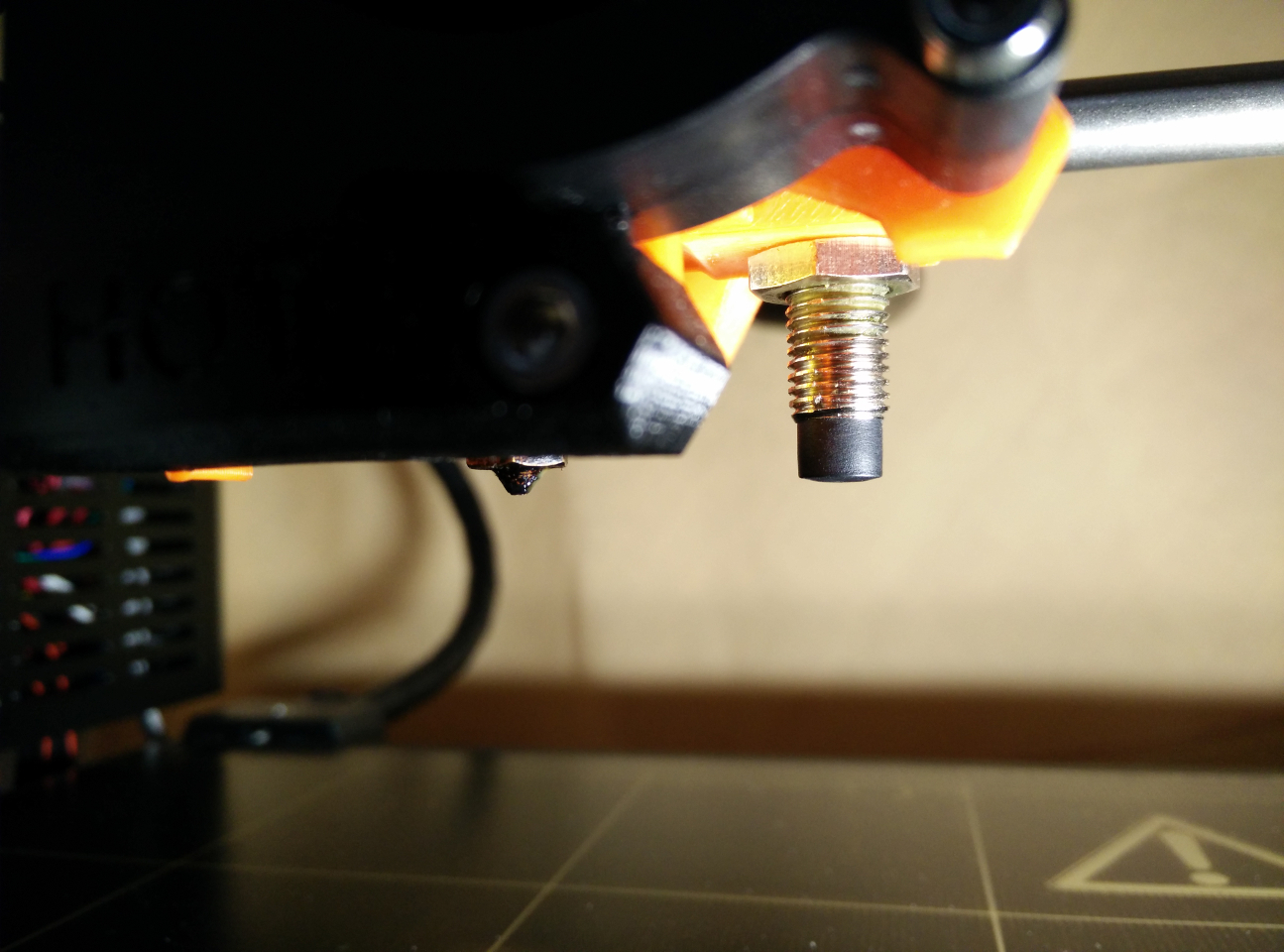

Here is the picture of my deformed PINDA probe. Noticed the deformed rubber part, you can tell the bottom curve down and I believe it is suppose to be flat. Does it affect the performance and readings??

Here is my problem, I started a print the other day and I noticed that the first layer is too high and it would not stick to the bed. Please note that I did not modify any settings from my previous print because I am printing the same file again. Then I noticed that my probe is deformed and the rubber part seats below the nozzle, which makes the first layer too high to make it stick to the bed.

Then, I raised the probe back up to 1mm above the nozzle to see if it solve the problem. I then redo the XYZ calibration and it failed at 3 of 4 of the first stage of calibration. I am sure I did not touch anything else and belt seems tight as guitar string on X & Y. I can see the red LED on the probe lit up and goes out if I put my metal wrench underneath it. I have no clue what went wrong.

Does anyone have the same problem? Please let me know if someone has the solution. Thanks

Re: Is my PINDA broken because it deforms?

I don't think the shape of the encapsulating plastic will have any affect on your PINDA.

Not sure why things shifted, but I notice you have the MK2 PINDA holder. The MK2S holder is far superior, and you might want to print that one if you have time.

People have noticed that if they have the PINDA near the bed (low Z) while pre-heating prior to the Z-Calibration they get strange results. Many upgrade their "Start GCode" in the slicer to home then up Z to 125 or so before pre-heating and people seem to think that improves the repeatability of the PINDA. Here is some example START GCODE that does this, and also does the calibration at 170 to prevent the nozzle oozing during the 9 point testing and leaving little drips:

M115 U3.0.12 ; tell printer latest fw version

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; extruder relative mode

M104 S170; Extruder to 170

M140 S[first_layer_bed_temperature] ; set bed temp

G28 W ; home all without mesh bed level

G1 X0 Y0 Z125; home X axis Lift to 125

M190 S[first_layer_bed_temperature] ; wait for bed temp

M109 S170 ; wait for extruder temp to hit 170

M104 S[first_layer_temperature] ; set extruder temp

G80 ; mesh bed leveling while rising in temp

G1 Y-3.0 F1000.0 ; go outside printing area

M109 S[first_layer_temperature] ; wait for extruder temp if needed

G92 E0 ; reset extrusion distance

G1 X100.0 E9.0 F1000.0 ; intro line

G1 X200.0 E12.5 F1000.0 ; intro line

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Is my PINDA broken because it deforms?

I planed to print the MK2S PINDA holder. However, I cannot even pass the XYZ calibration because of my probe.

Re: Is my PINDA broken because it deforms?

It sounds like your PINDA probe is too high. It should be about 0.6mm higher than the nozzle tip.

Try following these instructions and see if that gets you to a successful XYZ calibration. If not report back the results form each step and we can help find out what is going wrong.

If the light goes out when you put metal under it, the PINDA probe is working fine, it might just be too high to trigger. (Or you may have an XY problem where it is looking in the wrong place.) Try those steps above and let us know.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Is my PINDA broken because it deforms?

I did a further test on my PINDA probe and it seems like the probe get less sensitive to the heated bed because it sometimes pickup the destination points on the bed and sometimes it does not. My probe is seated almost the same height as the nozzle, and there is no way I can print anything with such setting. Still, I could not even finished the XYZ calibration process. So, I believe I get a pinch cable somewhere along the line. or the destination points on the heated bed is degraded. How can I fix it?

Re: Is my PINDA broken because it deforms?

stephen.I2

It is impossible for us to diagnose or help you with the limited description you have provided, which seems to have more conclusions you have drawn, than direct observations of the setup.

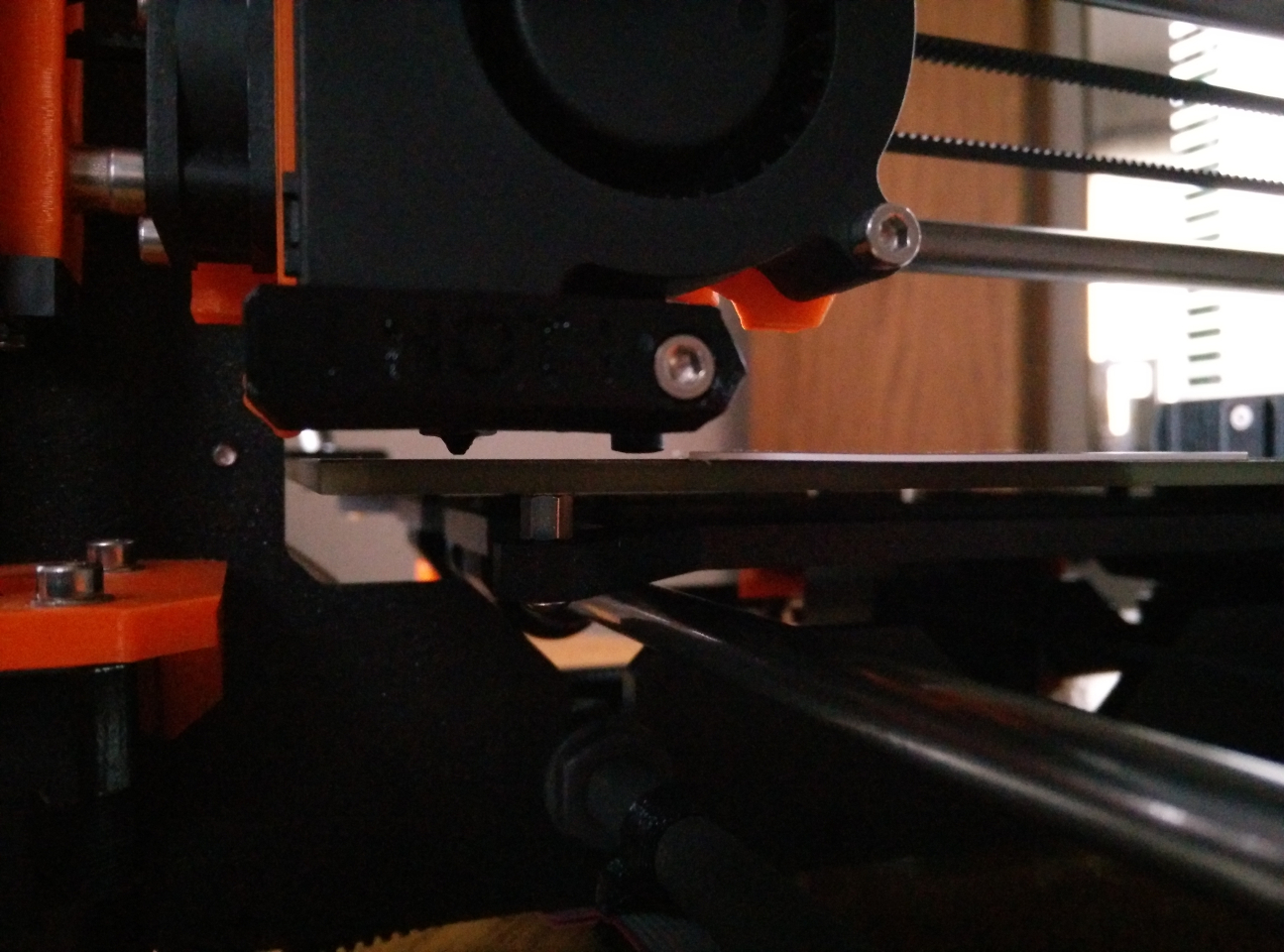

1) Can you provide a photo of the PINDA setting relative to the nozzle. E.g. Put the nozzle down very close to - or touching - the bed, and take a photo of where the PINDA sensor is. Can you slide a credit card under the PINDA in this configuration? The images you posted are hard to tell because there is no reference to perspective, but it looks like the PINDA is 2mm or so above the nozzle which it too high. Again, impossible to really tell from your photo, so if you could take another photo with the nozzle touching the bed, and something of known thickness (e.g. a credit card) next to it to judge the gap size.

2) When the PINDA sensor comes down to test point 1, or a Z calibration, does it come down in the little dashed circle on the bed, or is it offset in X Y?

3) If you put the nozzle down near the bed, and move the nozzle to other locations around the bed, is that spacing nearly constant, or is the bed much closer to the nozzle at some parts of the bed than others?

4) You say the XYZ calibration process does not finish. Please explain what it does do at each step. And what the printer says. Does it drag on the paper? Does is stop with a failure message? Do you shut it off? On what points?

The more descriptive you can be with what you see the quicker we can help find an isolate the issue, and get you printing again.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Is my PINDA broken because it deforms?

I'll get some more info and pictures of my issue over the weekend. Thanks.

I can answer the rest of the question:

2) When the probe comes down to test point 1, it does come down in the center of the dotted circle on the print bed lower left hand corner.

3) If I put the nozzle down near the bed, it seems like it has even distance between the entire bed.

4) I go to Calibration > XYZ Calibration. It begins the calibration process. Sometimes, it stopped at the first calibration point, sometimes it stopped at the 3rd point, and sometimes it passed all four points and went to the detail 9 point calibration and stop at one of the point and never finished the whole process. the error message is "XYZ calibration failed. Bed calibration point was not found."

As I mentioned before, I did not touch the printer at all and it did finished my print beautifully the day before. The next day when I start the print the nozzle seat way too high because I showed on the first layer. It looks like it print in the air. So, I noticed that the rubber part of the probe deformed and stretched way lower then nozzle, so I adjusted it back up and redo the XYZ calibration. And it never get to finish the calibration process.

Thanks.

Re: Is my PINDA broken because it deforms?

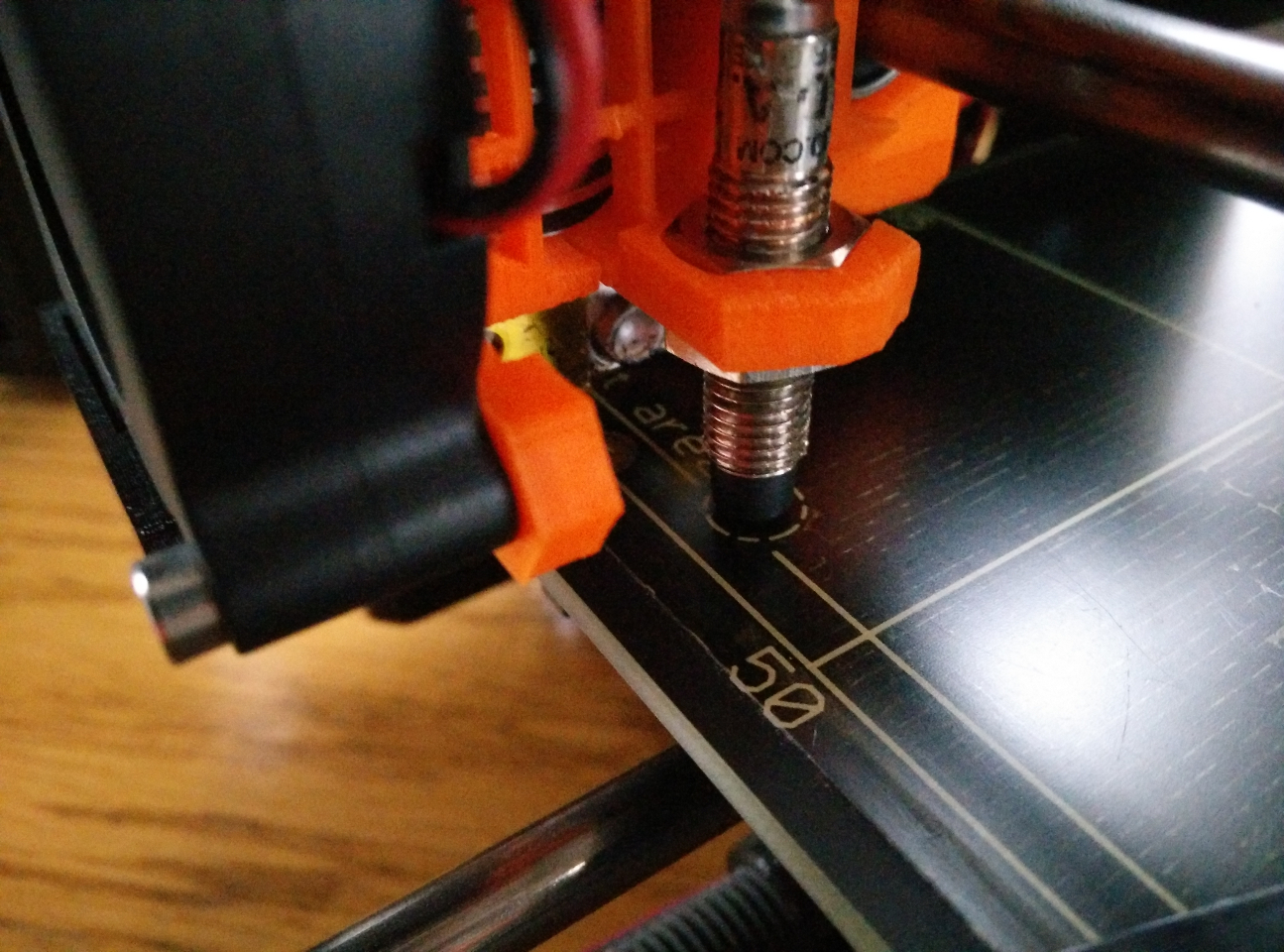

Here is the photos as requested.

This the the current height of my PINDA and nozzle when I did AUTO HOME. Credit card showed next to the probe.

Notice that it is almost dead center in the dotted circle at the lower left corner on the bed.

This is the ERROR message that I got during the XYZ calibration.

When I do the mesh bed leveling, sometimes it did finish all 9 calibration points and home. Sometimes, it just crashed to the bed in some calibration points. Any idea?

Re: Is my PINDA broken because it deforms?

These photos are excellent. Thank you.

You have the PINDA nice and low (and as you said, possibly too low).

Your X-Y location is correct.

I am assuming the PINDA light is ON when not near the calibration points.

This is starting to sound like a bad PINDA, but I want to walk through one more thing.

What version of the firmware are you using? The XYZ Cal has changed a lot over the recent versions. I think re-flashing the machine with the latest version is a worthwhile test step.

When doing the XYZ Cal, the printer "searches" for the different calibrations points. Starting at 2, 4, 6, 8 and then repeats for 1-9. It starts high, and searches in XY and then slowly drops z step by step until the PINDA senses the calibration point (PINDA light will flicker off) it refines the measurements there, and then moves on. You should have a piece of paper under the nozzle while it is doing this - in case it starts to drag you can shut off the printer before the nozzle digs in as the printer keeps dropping Z to find the points. It does not seem that you are turning off the printer - but the printer is giving you an error message. Can you describe what the printer does during the XYZ cal before it gives you that error?

Thanks for being patient with us. It is hard to "see" remotely.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Is my PINDA broken because it deforms?

The PINDA probe light is OFF when it is near the calibration points. Under "show end stop" menu, it will change from 0 to 1 on the Z if it is close to the calibration point or metal.

I am using firmware version 3.0.10. Not the latest, but I believe this version have some improvement on the calibration process.

When doing the XYZ calibration, it start at 2, and as you said, it starts high on gradually drops and search near the calibration point. The LED on probe did flick while it was searching near the point. Then it moves fast from left to right and gradually from backward to forward to look for the exact point (As usual XYZ calibration process on point 2,4,6,8). However, it just spit out the error message that I just shown on the photo after awhile of searching.

I did put a paper on the bed during the calibration process, and I did turn off the printer once it hit the bed.

Re: Is my PINDA broken because it deforms?

I would try firmware 3.0.12 (I am using this one) and see if that helps. It is possible your firmware is "corrupt" and re-flashing it will fix it. The new version should help too.

(3.0.12-RC2 claims to have improved XYZ Calibration, but I am waiting to jump to it - it might be worth your while to try that.)

If that does not fix it, then I think you have a bad PINDA, and should "chat" with PRUSA support and get a replacement.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Is my PINDA broken because it deforms?

Thanks Arron for all your input. And thanks for Shane from PR technical support to straighten it out by replacing my bad PINDA. Their service is top notch and I appreciated their patient and kindness for their customers. Awesome.