Flex3drive

Hi all,

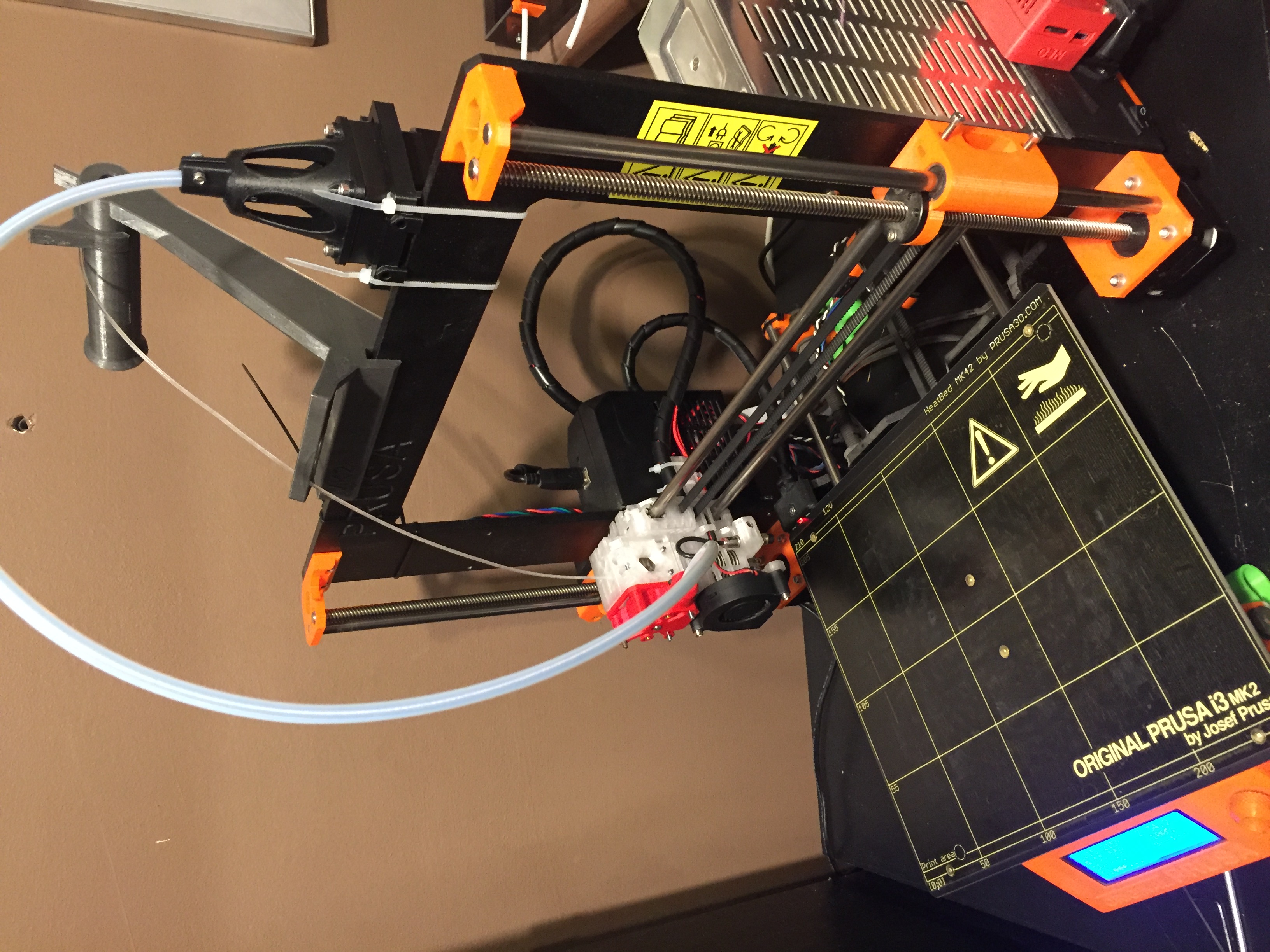

I have two flex3drive NEMA adapters for an ongoing 3d printer project .

https://flex3drive.com/flex3drive/f3d-dda/

They where laying around so i i gave it a try and mounted one on the prusa I3 MK2.

Motor moved to the back of the prusa and direct drive adapter onto the carriage to save some weight.

It is a 40:1 reduction so i had to up the e-steps a bit by using the M92 E7600.00 command.

Acceleration was very slow, so i used M201 E500.

Helped a bit but not that much.

Anyone using the flex3drive NEMA adapter to ?

Any ideas for better settings ?

Thanks !

Re: Flex3drive

This interests me, could you post some pictures ?

How is the print quality ? Also pic ?

Thanks a lot!

Re: Flex3drive

This would be brilliant for very high-res prints, but not so good on loading and unloading filament (missed steps) and unfortunately would be unworkable on the MMU with filament changes (up to 100mm/s extruder speed required)

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Flex3drive

Mounted and extrusion works ok.

Less weight on the extruder carriage means less resonance and faster possible x movements.

Offcourse if material will let you extrude (and bond) faster...

My goal is taking weight off for less jerk/resonance, speed is not that important to me.

I need a responsive system though cause i want to try "velocity painting"

https://www.velocitypainting.xyz/blog/category/cool-prints/

Since it's a 40:1 reduction for the Flex3drive, the E motor needs to spin 40 times faster, which is not a problem.

The problem is that it needs to halt and spin the other way nearly instant to retract.

Now i'm facing the problem that my Prusa NEMA stalls. (high or silent mode don'make a diff.)

http://forums.reprap.org/read.php?1,656132

This page sugests to tune the VREF.... How can you do that best on a Rambo mini ?

Re: Flex3drive

This page sugests to tune the VREF.... How can you do that best on a Rambo mini ?

M907 E750

Where 750 is the approximate current limit in mA.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Flex3drive

Just went back from Flex3Drive DDA setup on my i3 MK2 (mostly MK2 ;).

TL;DR: It is unreliable.

It is great idea, but... :

1) Loading/unloading filament is a pita. It does not work from menu, because extruder motor won't rotate that fast to unload filament necessarily fast to prevent clogging on the outlet. You have to loosen extruder idler to load/unload. p-i-t-a...

2) It relieves about 200g from extruder carriage, but it seems that it has almost no effect on printout (looking on ringing,etc...)

3) Its obvious that you need to tinker heavily with printer's working parameters via specific GCODE (microstepping, step/s per mm, speeds, accelerations, jerks, extruder current), but even with "overdrive" setup your extruder won't stop momentarily and retract necessarily fast. Its pure math - retraction need to be fast as hell, but when you have 1:40 reduction, the time for retraction is at least 40x higher than normal -> stringing like hell...

4) It may have effect on small nozzles (0.25) printing narrow layers (0.1mm), but it has no effect during nominal 0.4mm/0.15mm optimal or 0.2mm.

5) It noisy... very noisy. I can hear my MK2 @ igus drylin bearings standing 2m aside from me - it is not interfering with my mind :), but F3D makes it unpleasantly louder.

And last :

6) If it is good, Jo Prusa would adapt it before 🙂

(Sorry for image rotation...)

And of course, I might put more work into it, but I need stable and reliable machine...