Extruder Gear Replacement Tip on MK2

After printing almost a whole spool or Colorfabb XT CF-20 I began to notice filament flow issues in my prints. Tonight the problem became clear when printing the part shown below. The regular nature of the under extruded gaps in the print prompted me to look at the extruder gear more closely. At first glance the gear looked ok , but under strong light I realized that the teeth had become quite worn from the abrasive carbon fiber filament. The wear was worse on one side, causing the filament to slip on every revolution.

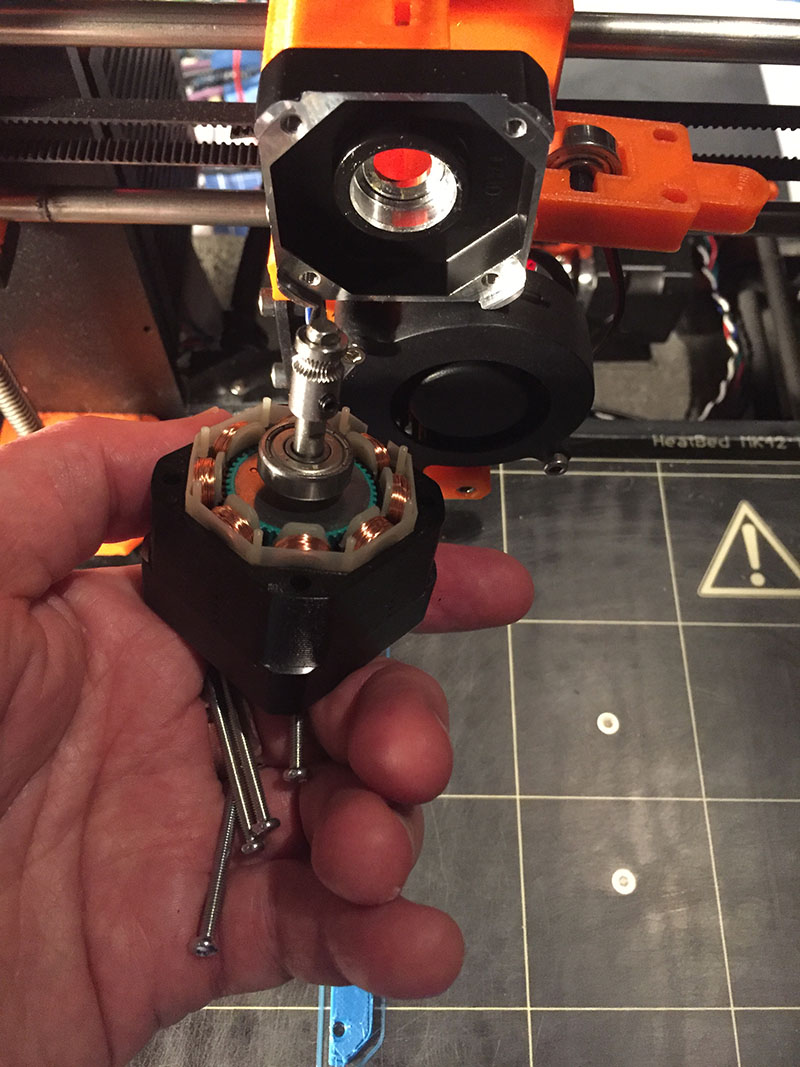

But, hey, no problem, I bought a couple of spares anticipating this would happen... but how to swap out the part? There's not enough room to slide the gear off the end of the shaft with the motor installed, and only one of the extruder motor screws is accessible from the back of the carriage. This meant the whole front section of the carriage assembly would need to be taken apart. Then it hit me that maybe I could simply take the motor apart! I took out the 4 screws holding the motor body together, and a with a gentle wiggle the motor popped apart so I could get off the old gear and install the new one. Within 10 minutes from start to finish I was printing again!

Worn gear:

Hope this is useful to someone!

Jim

Re: Extruder Gear Replacement Tip on MK2

Great tip - I was trying to clean my extruder and dropped the little set screw that got caught in the hinge, etc. Took way longer than it should have to get it back running. Wish I knew then what I know now. Thanks!

Re: Extruder Gear Replacement Tip on MK2

While I have no personal experience with this, it is my understanding that disassembly of a stepper motor is likely to result in permanently reduced torque due to partial demagnetization. I believe that the final manufacturing step is properly magnetizing the motor with a special jig.

Did a bit of googling and found a number of sites that support this theory but nothing definitive.